Regular Kitchen Suppression Inspections in Spring Lake are crucial for maintaining fire safety standards. Professional evaluators check sprinkler heads, valves, alarms, and more, identifying issues like blocked heads or corrosion to ensure system reliability. Adhering to local regulations and best practices through inspections, cleaning, and proper maintenance prevents safety hazards, legal penalties, and promotes proactive fire safety measures in Spring Lake kitchens.

In the heart of any kitchen lies a critical life safety feature: the suppression system. To ensure optimal performance and fire protection, regular Kitchen Suppression Inspection Spring Lake is paramount. This article delves into the intricacies of these systems, guiding property owners and managers through essential maintenance practices. From understanding key components to identifying common issues, we explore what to expect during Fire Suppression Compliance Checks. Discover best practices for hassle-free suppression system troubleshooting and the vital role professionals play in keeping your kitchen safe.

- Understanding Kitchen Suppression Systems: An Overview

- Importance of Regular Inspection and Maintenance

- Key Components to Check During a Kitchen Suppression Inspection in Spring Lake

- Common Issues and Their Solutions: Troubleshooting Tips

- Fire Suppression Compliance Checks: What to Expect

- Best Practices for Ensuring Optimal System Performance

- The Role of Professionals in Kitchen Suppression System Troubleshooting

Understanding Kitchen Suppression Systems: An Overview

Suppression systems in kitchens are critical components designed to protect against fires and ensure safety for occupants. These systems work through a network of pipes, nozzles, and fire suppression agents, such as gas or water, to extinguish or control fires at their source. Regular kitchen suppression system inspections are vital to maintain compliance with fire safety regulations, like those enforced by local authorities in Spring Lake.

During a kitchen suppression inspection, professionals check for any signs of damage, corrosion, or misalignment in the system’s components. They assess the functionality of each nozzle and ensure proper agent distribution. Fire suppression compliance checks also involve verifying that all valves, controls, and alarms are operating as intended, allowing for swift response in case of an emergency. By conducting these thorough inspections, Spring Lake residents can have peace of mind knowing their kitchen is equipped with a reliable fire suppression system, adhering to the highest safety standards.

Importance of Regular Inspection and Maintenance

Regular inspections and maintenance are crucial for any kitchen suppression system in Spring Lake. These systems play a vital role in fire safety by quickly suppressing cooking grease fires, which can be particularly challenging to extinguish. Over time, however, they can become contaminated or malfunction, leading to potential hazards. Kitchen suppression inspection services ensure that these systems are in optimal condition and compliant with local fire codes.

During a kitchen suppression inspection, professionals will thoroughly evaluate the system’s components, including the gas lines, sensors, and nozzles. They also check for any signs of damage, corrosion, or leaks. Regular compliance checks help identify issues early on, preventing more serious problems that could compromise safety and lead to costly repairs or even legal penalties.

Key Components to Check During a Kitchen Suppression Inspection in Spring Lake

During a kitchen suppression inspection in Spring Lake, several key components should be thoroughly checked to ensure fire suppression compliance. The first step is to verify that all sprinkler heads are free from obstructions and in good working order. Even a single blocked head can significantly impair the system’s effectiveness during a fire event. Inspectors should also examine the main supply valves for any signs of corrosion or damage, ensuring they are fully operational and accessible without difficulty.

Additionally, the control panel must be evaluated to confirm proper functionality and clear labeling. All alarms, indicators, and discharge mechanisms should be tested to ensure they activate as intended. Furthermore, check fire extinguishers located in the kitchen area for date compliance, proper placement, and full charge status. Regular maintenance logs and up-to-date documentation are also crucial elements to verify during these inspections, ensuring that all components of the kitchen suppression system are in accordance with local fire safety standards and regulations.

Common Issues and Their Solutions: Troubleshooting Tips

When it comes to kitchen suppression systems in Spring Lake, common issues can range from faulty sprinkler heads to inadequate maintenance. A thorough Kitchen Suppression Inspection is crucial for ensuring fire suppression compliance checks and identifying potential problems before they escalate. One frequent issue is blocked or painted sprinkler heads, which hinder their ability to discharge water effectively during a fire. Regular cleaning and inspecting these heads, especially in kitchens with high grease buildup, can prevent this problem.

Another common concern is corroded piping, which can lead to system failure. Corrosion often occurs due to moisture and chemical exposure. Conducting routine visual inspections and maintaining proper ventilation can help mitigate corrosion. Additionally, checking for leaks and sealing any gaps or cracks promptly is essential to avoid water damage and maintain the integrity of the suppression system. Staying proactive with these troubleshooting tips ensures a well-functioning kitchen suppression system, enhancing fire safety in Spring Lake establishments.

Fire Suppression Compliance Checks: What to Expect

When it comes to fire suppression systems in commercial kitchens, such as those in Spring Lake, regular inspections are non-negotiable. Known as Kitchen Suppression Inspections, these compliance checks are designed to ensure your system is functioning optimally and adheres to local fire safety regulations. During these inspections, professionals will meticulously assess various components of your kitchen suppression system, including the sprinkler system, fire alarms, detection devices, and more.

Expect a thorough review of your system’s design, installation, maintenance records, and operational capabilities. The goal is not only to identify any potential issues or deficiencies but also to verify that your system is properly integrated into your kitchen layout and complies with relevant codes. By conducting these Fire Suppression Compliance Checks, you’re taking a proactive step towards fire safety, providing peace of mind for both your business and the local community.

Best Practices for Ensuring Optimal System Performance

Maintaining a kitchen suppression system is crucial for fire safety in Spring Lake establishments. Regular inspections and thorough cleaning are best practices to ensure optimal performance. A Kitchen Suppression Inspection should include checking all components, testing the system’s functionality, and verifying proper maintenance records. Adhering to these protocols helps guarantee that the suppression system is ready to activate in case of a fire, providing swift and effective protection.

Fire suppression compliance checks are essential for meeting local regulations and maintaining a safe environment. Property owners and managers should schedule routine inspections with certified professionals who can identify potential issues, offer solutions, and ensure the system’s reliability. By implementing these best practices, Spring Lake businesses can mitigate risks and protect their assets effectively.

The Role of Professionals in Kitchen Suppression System Troubleshooting

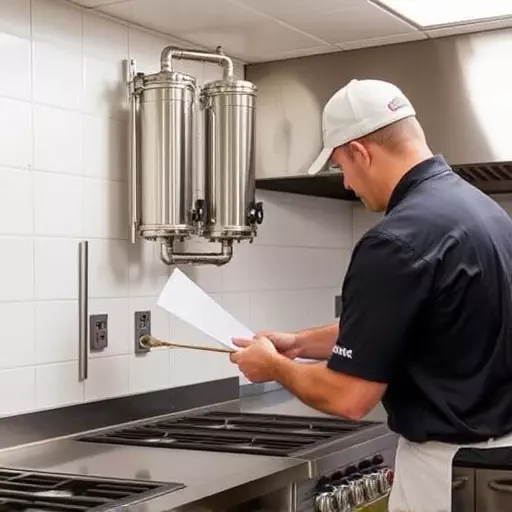

When it comes to kitchen suppression system troubleshooting in Spring Lake, professionals play a pivotal role in ensuring safety and compliance. They are equipped with the knowledge and expertise to handle complex fire suppression systems, which often involve intricate mechanisms like gas suppression or clean agent technology. These specialists can perform thorough inspections, identifying any potential issues or defects that may compromise the system’s effectiveness during an emergency.

By conducting regular kitchen suppression system inspections, professionals help commercial kitchens meet important fire suppression compliance checks. They verify proper system functionality, check for necessary maintenance, and ensure all components are in good working order. Their expertise allows them to provide valuable insights on improving fire safety protocols, making kitchens safer for everyone.