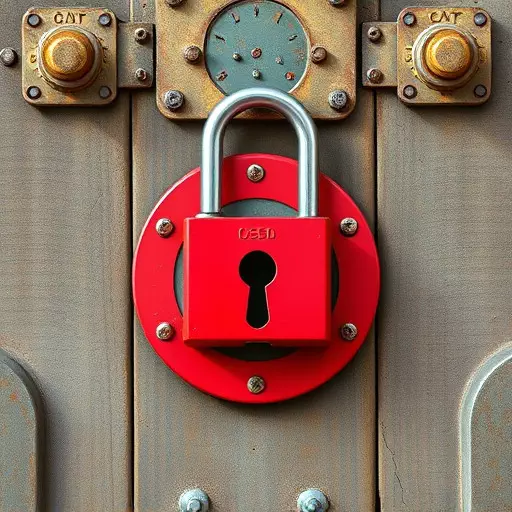

Energy isolation through tailored lockout tagout program development is crucial for industries using hazardous energy sources. Adhering to OSHA lockout tagout standards, these programs educate workers on safe procedures, locking device selection, and best practices to prevent injuries from unexpected energy release. Lockout tagout training programs significantly reduce risks, making them an essential part of comprehensive workplace safety initiatives.

In today’s industrial landscape, energy isolation risk assessments are paramount for workplace safety. This comprehensive guide explores the critical components of effective lockout/tagout (L/T/O) program development, aligned with OSHA lockout tagout standards. We delve into best practices, key considerations, and lockout tagout training programs essential for mitigating risks associated with energy sources. By understanding these elements, folks can foster a culture of safety, ensuring a robust and compliant environment.

Energy isolation is a critical aspect of workplace safety, especially in industries where hazardous energy sources are commonly used. A comprehensive risk assessment for energy isolation focuses on identifying potential hazards and implementing effective control measures to prevent accidents. This involves understanding OSHA lockout/tagout standards, which provide guidelines for safeguarding employees during equipment maintenance or servicing.

One key component is the development of a tailored lockout tagout program that aligns with industry-specific requirements. These programs ensure that workers are trained in the proper procedures for isolating energy sources, using appropriate locking devices, and following safe work practices. Effective training on these protocols can significantly reduce the risk of injuries related to unexpected energy release, making it an essential part of any comprehensive safety program.