Process Safety Management Consulting (PSM) is a specialized service ensuring safe industrial operations in high-risk sectors through robust hazard identification. PSM leverages comprehensive Process Hazard Analysis (PHA) to identify, assess, and mitigate risks by examining equipment, materials, and operational dynamics. PHA uses tools like fault tree analysis and event tree analysis to uncover hidden dangers, enabling tailored risk management strategies for enhanced process safety. Root Cause Analysis (RCA), integrated with hazard identification techniques, helps organizations proactively address incident root causes, fostering continuous improvement and a robust safety culture.

“Unraveling the intricacies of Process Safety Management (PSM) is paramount in industries where processes are complex and risks are high. This article explores the foundational concepts of PSM, shedding light on its significance in mitigating hazards. We delve into advanced hazard identification techniques, a pivotal step in PSM, which help identify potential dangers early.

Furthermore, we present Process Hazard Analysis (PHA), a robust methodology transforming theoretical knowledge into practical applications for process safety enhancement. By examining root causes, PHA empowers industries to prevent catastrophic events and create safer working environments.”

- Understanding Process Safety Management Consulting (PSM) and Its Foundation

- Unveiling Hazard Identification Techniques: A Crucial Step in PSM

- Delving into Process Hazard Analysis (PHA): Methodology and Applications

- The Impact of Root Cause Analysis on Enhancing Process Safety

Understanding Process Safety Management Consulting (PSM) and Its Foundation

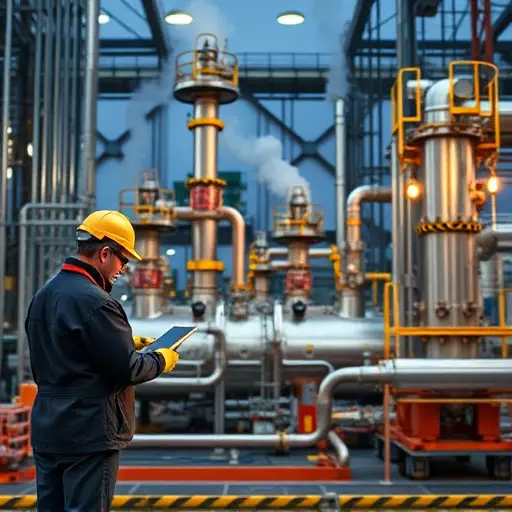

Process Safety Management Consulting (PSM) is a specialized service that plays a pivotal role in ensuring the safe operation of industrial processes and facilities. It focuses on identifying, assessing, and mitigating risks associated with chemical, pharmaceutical, petrochemical, and other high-risk industries. PSM is built upon a robust foundation of hazard identification techniques and process hazard analysis (PHA), which serve as the cornerstone for developing effective safety management systems.

Through thorough PHA, consultants systematically examine processes to identify potential hazards and evaluate their severity and likelihood. This involves a comprehensive review of facility operations, equipment, materials, and relevant industry standards. By employing advanced hazard identification techniques, PSM experts can uncover subtle risks that might otherwise be overlooked. These methods ensure a holistic understanding of process safety, fostering a culture of continuous improvement and enhanced operational resilience.

Unveiling Hazard Identification Techniques: A Crucial Step in PSM

Unveiling Hazard Identification Techniques plays a pivotal role in Process Safety Management (PSM). This initial step involves employing robust hazard identification techniques such as Process Hazard Analysis (PHA) to unearth potential risks lurking within industrial processes. By systematically assessing the interconnection of equipment, materials, and human actions, PSM consultants can identify hazards that may go unnoticed during routine operations.

Effective hazard identification techniques transcend mere checklists or standardized procedures. They demand a deep understanding of process dynamics, system failures, and human factors. Through detailed scenario analysis, fault tree analysis, and event tree analysis, potential accidents are dissected, their causes explored, and the likelihood of occurrence evaluated. This meticulous approach empowers PSM consultants to implement proactive measures, enhancing overall process safety and mitigating catastrophic risks.

Delving into Process Hazard Analysis (PHA): Methodology and Applications

Delving into Process Hazard Analysis (PHA) involves a systematic exploration of potential hazards within industrial processes. As a cornerstone of process safety management consulting, PHA employs robust hazard identification techniques to assess risks and implement effective risk mitigation strategies. By meticulously examining each stage of a process, from raw material input to final product output, consultants can uncover hidden dangers that might otherwise go unnoticed.

The methodology behind PHA is both comprehensive and application-focused. It leverages a range of qualitative and quantitative tools to analyze complex systems. These include fault tree analysis, event tree analysis, and what-if scenarios, enabling consultants to identify, quantify, and prioritize potential hazards. This data-driven approach ensures that risk management strategies are tailored to the specific needs and operational contexts of each facility, enhancing overall process safety.

The Impact of Root Cause Analysis on Enhancing Process Safety

Root Cause Analysis (RCA) plays a pivotal role in enhancing process safety within Process Safety Management (PSM). By employing robust hazard identification techniques, such as Process Hazard Analysis (PHA), organizations can uncover the fundamental reasons behind incidents or near-misses. This proactive approach allows for the development of effective risk mitigation strategies that go beyond addressing symptoms.

RCA enables a deeper understanding of process failures, leading to more comprehensive and targeted improvements in PSM consulting. By identifying and addressing the root causes, organizations can significantly reduce the likelihood and severity of future hazards, ultimately fostering a safer operating environment. This continuous improvement methodology ensures that lessons learned are systematically incorporated into existing processes, contributing to a robust and adaptive safety culture.