The article discusses the role of pavement milling and grinding in maintaining safe and efficient roadways, highlighting Toledo, Ohio as a leading example of best practices. The city's Department of Transportation employs advanced equipment and real-time monitoring systems to minimize traffic disruptions and enhance worker safety while producing high-quality road surfaces. Toledo's approach not only showcases the cost-effectiveness and sustainability of recycling milled materials on-site but also underscores the importance of specialized training for operators in this field. The city's commitment to innovation, with its adoption of automation, real-time data analytics, sensors, and machine learning algorithms, has positioned Toledo as a vanguard in pavement milling and grinding practices, offering insights into predictive maintenance and setting new industry standards. This evolution in technology and methodology in Toledo exemplifies the transformative impact of advanced techniques in urban infrastructure maintenance and rehabilitation.

Effective productivity within infrastructure maintenance is a cornerstone of efficient urban development. This article delves into the nuances of pavement milling and grinding, highlighting strategies and technological advancements that optimize these processes. From economic evaluations to environmental impact assessments, we explore the multifaceted aspects of pavement milling and grinding operations, with a particular focus on successful initiatives in Toledo, Ohio. Additionally, we examine the importance of operator training and skill development, as well as the anticipation of future trends that will shape the industry’s trajectory. Join us as we navigate through the complexities of this critical urban infrastructure maintenance practice.

- Optimizing Pavement Milling and Grinding Operations: Best Practices

- The Role of Advanced Technology in Enhancing Efficiency in Pavement Milling and Grinding

- Cost Analysis: Understanding the Economic Implications of Pavement Milling and Grinding Projects

- Environmental Considerations in Pavement Milling and Grinding Operations

- Case Study: Successful Pavement Milling and Grinding Initiatives in Toledo, Ohio

- Training and Skill Development for Operators in the Pavement Milling and Grinding Industry

- Future Trends and Innovations in Pavement Milling and Grinding Techniques

Optimizing Pavement Milling and Grinding Operations: Best Practices

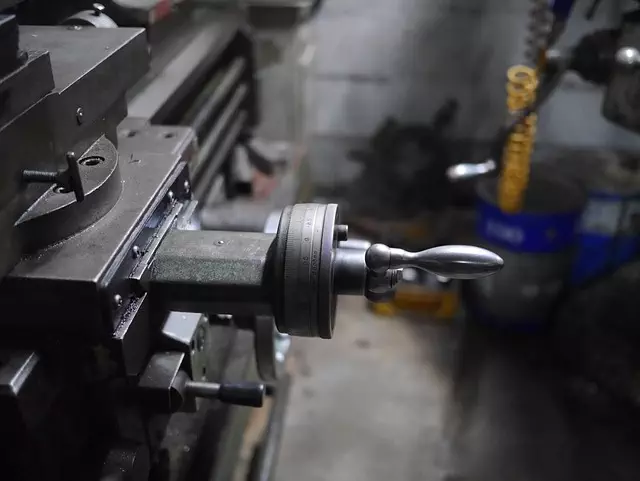

In the realm of infrastructure maintenance, pavement milling and grinding plays a pivotal role in ensuring roadways are safe and efficient. This process involves removing the top layer of asphalt from existing roads, which can then be repurposed or replaced as needed. Optimizing these operations through best practices is crucial for maximizing efficiency and cost-effectiveness. One key practice is the precise planning and scheduling of milling and grinding activities, taking into account traffic patterns, weather conditions, and available equipment to minimize disruptions. Advanced planning also allows for the coordination of resources such as personnel, machinery, and material supply, which is essential for maintaining project timelines and reducing downtime.

In Toledo, Ohio, these operations are conducted with a high degree of expertise and attention to detail. The city’s Department of Transportation employs state-of-the-art equipment and techniques to ensure that pavement milling and grinding are performed with minimal impact on traffic flow and maximum safety for both motorists and workers. Best practices in Toledo include the utilization of variable speed milling machines, which adapt to changing conditions on the road, and the implementation of real-time monitoring systems to track the progress and quality of the work. These measures contribute to the overall success of the pavement milling and grinding projects, ensuring that the city’s infrastructure is consistently maintained at a high standard. The experience and methods honed in Toledo can serve as a benchmark for other municipalities looking to enhance their own pavement milling and grinding operations.

The Role of Advanced Technology in Enhancing Efficiency in Pavement Milling and Grinding

In recent years, the integration of advanced technology has significantly enhanced the efficiency of pavement milling and grinding operations. These sophisticated systems have streamlined the process, leading to reduced time and costs associated with infrastructure maintenance and renovation. For instance, in Toledo, Ohio, where pavement milling and grinding are common practices due to the region’s dense road network, the adoption of cutting-edge machinery and techniques has been instrumental in improving project outcomes. Technologies such as GPS navigation and machine control systems enable precision work, ensuring that only the necessary material is removed without compromising the integrity of the surrounding pavement. This not only optimizes material usage but also minimizes disruptions to traffic flow and local businesses. Furthermore, advancements in milling equipment have led to machines with higher durability and performance capabilities, allowing for longer operational hours and more consistent surface finishes. The use of these technologies has transformed the pavement milling and grinding process into a more sustainable and cost-effective approach to road maintenance, reflecting the industry’s commitment to continuous improvement and innovation.

Cost Analysis: Understanding the Economic Implications of Pavement Milling and Grinding Projects

Pavement milling and grinding operations play a pivotal role in road maintenance, rehabilitation, and construction projects. These processes involve removing the surface layer of asphalt to prepare for repairs or repaving. In the context of economic implications, a comprehensive cost analysis is indispensable for stakeholders considering pavement milling and grinding projects. The costs associated with these operations extend beyond the immediate equipment and labor expenses; they include material disposal, environmental impact mitigation, and the potential for traffic flow disruptions. For instance, in Toledo, Ohio, the cost-benefit analysis must account for local labor rates, disposal fees for recycled asphalt, and the efficiency gains from utilizing pavement milling and grinding methods to minimize long-term maintenance costs. These factors collectively influence the total economic impact of the project, necessitating a detailed financial assessment to ensure the project’s viability and cost-effectiveness over time.

The decision to undertake pavement milling and grinding is not solely based on the initial investment but also on the long-term savings and infrastructure quality it offers. In Toledo, Ohio, where transportation infrastructure supports both local commerce and interstate traffic, the longevity of the pavement post-milling is a critical consideration. The economic analysis must weigh the short-term expenses against the extended lifespan of the roadway, which translates to fewer future repairs and a smoother driving experience. Furthermore, the environmental benefits of recycling the old asphalt directly impact the cost-effectiveness and sustainability of the project, making it an attractive option for municipalities and contractors alike who prioritize eco-friendly infrastructure solutions. Understanding these economic implications is crucial for making informed decisions regarding pavement milling and grinding projects.

Environmental Considerations in Pavement Milling and Grinding Operations

Pavement milling and grinding operations play a critical role in modern infrastructure maintenance, particularly in urban environments such as Toledo, Ohio. These processes involve removing the worn-out surface course of pavements to prepare for repair or resurfacing work. Environmental considerations are paramount during these operations due to their potential impact on local ecosystems and air quality. The fine particles generated from milling and grinding activities can contribute to dust pollution if not managed properly, which necessitates the use of advanced dust suppression systems. These systems help in minimizing the release of particulate matter into the atmosphere, thereby reducing the environmental footprint of these operations.

Moreover, the reuse and recycling of milled pavement material are significant aspects of sustainability in pavement milling and grinding. In Toledo, Ohio, and similar regions, there is a concerted effort to process the milled material on-site into materials that can be reused in new construction projects, thereby reducing the need for virgin materials and the associated environmental impacts of their extraction and production. The effectiveness of these recycling efforts not only contributes to cost savings but also aligns with broader environmental goals, promoting a circular economy within the infrastructure sector. Operators must adhere to strict environmental regulations and best practices to ensure that these operations are conducted responsibly and sustainably.

Case Study: Successful Pavement Milling and Grinding Initiatives in Toledo, Ohio

Toledo, Ohio has set a benchmark for effective pavement milling and grinding operations through a series of successful initiatives. These efforts have significantly improved the city’s infrastructure maintenance and asset management strategies. The initiative leveraged advanced milling machines that efficiently removed defective road surfaces without disrupting the overall traffic flow. By utilizing these state-of-the-art machines, Toledo’s Department of Public Service was able to process large volumes of asphalt, repurposing it for new pavement construction and other projects. This not only reduced material costs but also promoted environmental sustainability by recycling materials on a large scale.

The results of these pavement milling and grinding initiatives have been tangible, with improved road conditions contributing to increased driver safety and smoother traffic flow. The city’s investment in this infrastructure modernization has paid off, as evidenced by reduced maintenance costs over time and the longevity of newly constructed roads. Toledo’s success story underscores the effectiveness of pavement milling and grinding techniques for urban renewal and maintenance, setting a precedent for cities with similar infrastructure needs. The case study serves as a testament to the benefits of embracing innovative solutions in public works projects, showcasing how pavement milling and grinding can lead to cost savings, improved road quality, and a more efficient city infrastructure.

Training and Skill Development for Operators in the Pavement Milling and Grinding Industry

Operators within the pavement milling and grinding industry play a critical role in infrastructure maintenance, and their proficiency directly impacts project efficiency and safety. Training and skill development are paramount to ensure these professionals can effectively manage advanced machinery used for pavement milling and grinding in Toledo, Ohio, and beyond. Comprehensive training programs focus on the proper operation of machines like milling machines and grinders, understanding the materials being worked with, and recognizing the varying conditions of roadways. These programs also emphasize safety protocols, as working with heavy machinery on busy roadways demands vigilance and expertise. Skill development in this field not only enhances productivity but also contributes to the longevity and quality of the repaired or maintained pavement surfaces. Advanced training centers, which may be found in areas with high industry activity like Toledo, Ohio, provide simulated environments for operators to practice their skills, ensuring they are well-prepared to handle real-world scenarios. By investing in continuous skill development, the industry ensures that operators can adapt to new technologies and methodologies, thereby maintaining a high standard of service in pavement milling and grinding operations. This commitment to training and skill enhancement is essential for the sustainable and efficient completion of projects in the infrastructure sector.

Future Trends and Innovations in Pavement Milling and Grinding Techniques

The field of pavement milling and grinding continues to evolve, with innovative techniques and technologies emerging to enhance efficiency, sustainability, and the quality of road maintenance and construction. Future trends in pavement milling and grinding involve the integration of advanced machinery that incorporates automation, precision, and real-time data analytics to optimize the milling process. These advancements aim to reduce the environmental impact associated with this heavy industry by minimizing dust, noise, and energy consumption. In Toledo, Ohio, for instance, the adoption of these cutting-edge methods not only improves project outcomes but also aligns with local regulations and community standards regarding environmental concerns.

Furthermore, the industry is seeing a shift towards more adaptive milling technologies that can handle a variety of pavement types and conditions. This includes developments in milling machines’ durability and versatility to tackle diverse materials from concrete to asphalt. The integration of sensors and machine learning algorithms enables predictive maintenance, ensuring machinery operates at peak performance and longevity. As these innovations become more prevalent, pavement milling and grinding operations in Toledo, Ohio, are expected to set new standards for safety, efficiency, and cost-effectiveness, positioning the region as a leader in road infrastructure maintenance and rehabilitation.