Pavement milling and grinding play a pivotal role in modern road maintenance, offering a sustainable and cost-effective approach to infrastructure renewal. This article delves into the multifaceted benefits and advancements within the field of pavement milling and grinding, highlighting its positive environmental and economic impacts. From detailed case studies, such as its application in Toledo Ohio, to the latest technological innovations enhancing the process, we explore the best practices for executing these operations and provide insights into future trends. Join us as we dissect the critical role of pavement milling and grinding in the realm of infrastructure management and sustainability.

- Uncovering Efficiency: The Role of Pavement Milling and Grinding in Sustainable Road Maintenance

- Pavement Milling and Grinding to Toledo Ohio: A Case Study in Asphalt Reclamation

- Technological Advancements in Pavement Milling and Grinding Machinery

- Environmental and Economic Benefits of Implementing Pavement Milling and Grinding Practices

- Best Practices for Executing Pavement Milling and Grinding Operations Effectively

- Future Outlook: Innovations and Trends in Pavement Milling and Grinding Technologies

Uncovering Efficiency: The Role of Pavement Milling and Grinding in Sustainable Road Maintenance

Pavement milling and grinding are pivotal processes in the sustainable maintenance of roads, offering significant environmental and economic advantages over traditional demolition and replacement methods. These techniques involve the removal of the top layer of asphalt or concrete from a road surface through mechanical cutting, which is then repurposed or recycled. In Toledo, Ohio, for instance, the city’s Department of Transportation has successfully integrated pavement milling and grinding into its infrastructure maintenance plan. This approach not only extends the lifespan of existing roads but also reduces landfill waste, as the reclaimed material can be used in new road constructions or other projects. The efficiency of these processes is evident in their ability to minimize traffic disruptions and complete maintenance work faster than conventional methods. Moreover, the recycled pavement material meets rigorous quality standards, ensuring the durability and safety of reconstructed roads. These eco-friendly practices are a testament to Toledo’s commitment to sustainable infrastructure management, setting a precedent for other municipalities to follow suit. The adoption of pavement milling and grinding technology in road maintenance not only contributes to resource conservation but also showcases the city’s proactive stance on reducing its carbon footprint and promoting environmental stewardship.

Pavement Milling and Grinding to Toledo Ohio: A Case Study in Asphalt Reclamation

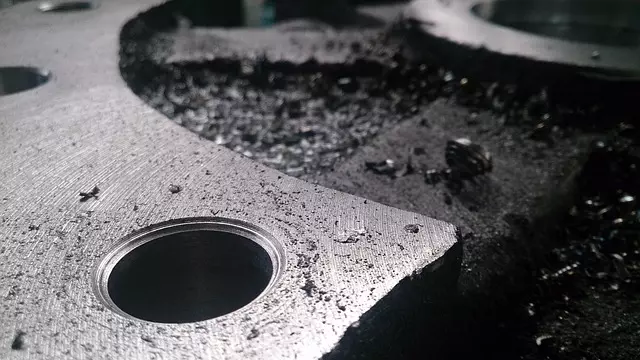

Pavement milling and grinding are efficient processes in the realm of asphalt reclamation, serving as critical components in maintaining and upgrading road infrastructure. In Toledo, Ohio, these methods have been instrumental in the city’s ongoing efforts to sustainably manage its pavement assets. The process begins with the precise removal of the worn-out asphalt surface, which is then ground down into uniform material. This not only exposes the existing pavement structure for assessment but also ensures that the reclaimed material can be effectively recycled and utilized in new construction projects.

The application of pavement milling and grinding in Toledo has been a model of efficiency and environmental responsibility. The city’s approach involves a multi-step process where the milled material is carefully collected, processed, and then incorporated into new asphalt mixes. This closed-loop system not only reduces the need for virgin materials but also minimizes landfill use. Toledo’s commitment to this reclamation practice demonstrates the city’s dedication to infrastructure renewal and sustainability initiatives, making it a compelling case study in the application of pavement milling and grinding techniques. The outcomes observed in Toledo underscore the effectiveness of these methods as a cost-effective and eco-friendly solution for urban road maintenance and development.

Technological Advancements in Pavement Milling and Grinding Machinery

In recent years, technological advancements in pavement milling and grinding machinery have significantly improved the efficiency and quality of road maintenance operations. These machines are instrumental in the process of selectively removing surface layers or full depth pavement sections to prepare for repairs, resurfacing, or reconstruction. The integration of advanced technologies such as GPS guidance systems has enhanced the precision of these machines, ensuring that only the targeted material is removed while minimizing disruptions to surrounding infrastructure. This precision not only reduces waste but also shortens project timelines and lowers associated costs. Furthermore, the development of more robust and durable milling machines capable of handling diverse pavement types has expanded their applicability. For instance, in Toledo, Ohio, local departments of transportation have utilized these advanced milling machines to maintain and improve road conditions effectively. The city’s commitment to infrastructure sustainability is evident through its adoption of state-of-the-art machinery that recycles pavement material on-site, further contributing to environmental conservation efforts. These technological advancements represent a leap forward in maintaining and upgrading our road systems with greater efficiency, longevity, and minimal environmental impact.

Environmental and Economic Benefits of Implementing Pavement Milling and Grinding Practices

Pavement milling and grinding represent a sustainable approach in road maintenance and reconstruction, offering significant environmental and economic benefits. These processes involve the removal of the surface course of asphalt pavements through mechanical means, which can then be reused or recycled. By employing pavement milling and grinding practices, cities like Toledo, Ohio, can effectively extend the life of existing roads while reducing landfill waste. The recycled materials from these operations not only conserve natural resources but also lower greenhouse gas emissions associated with producing new asphalt. This method minimizes the need for quarrying and transportation of raw materials, further contributing to reduced carbon footprints.

From an economic perspective, pavement milling and grinding practices in Toledo, Ohio, represent a cost-effective solution for infrastructure management. The reuse of recycled asphalt not only cuts down on material costs but also reduces labor expenses due to the efficiency of these processes. Additionally, investing in such sustainable techniques can lead to long-term savings for municipalities and government entities by decreasing maintenance and repair expenses over time. The consistent quality of the recycled material ensures a durable road surface, which translates into smoother travel conditions, enhanced safety, and a reliable infrastructure system that supports economic activity.

Best Practices for Executing Pavement Milling and Grinding Operations Effectively

Incorporating pavement milling and grinding into infrastructure maintenance is a critical step in maintaining road quality and safety. This process involves the removal of the surface course of an asphalt or concrete pavement to recycle the material back into new pavements. To execute pavement milling and grinding operations effectively, it is imperative to follow best practices that ensure efficiency, safety, and environmental sustainability. One of the key practices is pre-operation planning, which includes assessing the pavement condition, determining the optimal milling depth, and selecting the appropriate milling equipment for the job. In Toledo, Ohio, as in other locations, understanding the local regulatory framework and adhering to state-specific guidelines is crucial. This ensures compliance with environmental standards and local road conditions. Additionally, employing skilled operators who are trained in the latest techniques and safety protocols is essential for the success of the operation. Advanced milling machines equipped with precise control systems can adapt to various pavement structures, minimizing damage to underlying layers and maximizing material recovery. Furthermore, scheduling operations during optimal weather conditions, such as cooler temperatures, can enhance the quality of the ground material and reduce dust pollution. By integrating these best practices, pavement milling and grinding in Toledo, Ohio, not only extends the life of the road infrastructure but also contributes to a more sustainable construction process, reducing the need for virgin materials and minimizing the environmental impact.

Future Outlook: Innovations and Trends in Pavement Milling and Grinding Technologies

Pavement milling and grinding technologies have seen significant advancements in recent years, transforming the way roads are maintained and reconstructed. Innovations in these fields not only enhance the efficiency of road rehabilitation but also contribute to sustainability by recycling existing materials. In Toledo, Ohio, for instance, the application of cutting-edge pavement milling and grinding techniques is a testament to the region’s commitment to infrastructure improvements. These technologies enable the precise removal of road surface layers, allowing for the repair or replacement of underlying structures without complete road closure. The recycled materials from these processes can then be reused in new pavements, reducing landfill waste and saving on raw material costs. As these technologies continue to evolve, we can expect even greater integration of machine learning algorithms for predictive maintenance, improved sensor systems for real-time monitoring of pavement conditions, and more sophisticated milling machines with higher efficiency and lower emissions. The future outlook for pavement milling and grinding is one of innovation, with a focus on enhancing operational performance while promoting environmental sustainability.