“Unveiling the precision and potential of micro etching in the automotive industry, this comprehensive guide explores a revolutionary manufacturing process. From ‘Understanding Micro Etching Technology’ to ‘Applications of Micro etched Automotive Parts’, we delve into the intricate details and significant advantages it offers.

Oak Harbor, Ohio, emerges as a hub for advanced micro etching services, providing tailored solutions. Discover how this technology enhances automotive design and performance, ensuring reliability and precision with every cut.”

- Understanding Micro Etching Technology

- The Micro Etching Process: Step-by-Step

- Advantages of Micro Etching for Automotive Applications

- Material Considerations for Micro Etching in Ohio

- Applications of Micro Etched Automotive Parts

- Finding Reliable Micro Etching Services in Oak Harbor

Understanding Micro Etching Technology

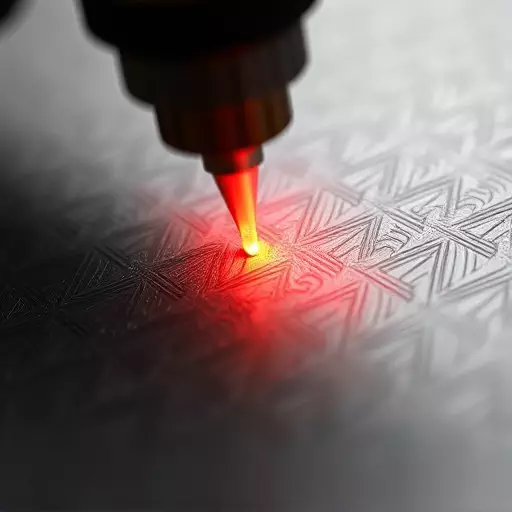

Micro etching is a highly precise and advanced manufacturing technology that has revolutionized the automotive industry. This process involves using specialized tools to create intricate patterns or structures on various materials, including metals and plastics, with microscopic accuracy. In Oak Harbor, Ohio, many automotive parts manufacturers are adopting this method to achieve unparalleled precision and quality in their components.

The micro etching process offers numerous benefits, such as enhanced durability, improved surface finish, and increased part functionality. It allows for the creation of complex geometries that traditional machining methods find challenging. By manipulating materials at a microscopic level, manufacturers can produce lighter, stronger, and more efficient automotive parts, contributing to better fuel efficiency and overall vehicle performance.

The Micro Etching Process: Step-by-Step

The Micro Etching Process in Oak Harbor, Ohio involves a precise and intricate series of steps to achieve detailed designs on automotive parts. It begins with the preparation of the surface, ensuring it’s clean and free from contaminants. Next, a photoresist is applied, acting as a mask that protects certain areas while exposing others to an ultraviolet light, which precisely hardens the resist according to the desired pattern.

Following this, micro etching commences using a specialized plasma etcher. This tool selectively removes the exposed material, revealing the desired intricate patterns. The process is highly controlled, allowing for precise depth and dimensionality. Once etching is complete, the photoresist is carefully stripped away, leaving behind the exacting design etched into the automotive part. The benefits of micro etching are significant in the automotive industry, enabling enhanced aesthetic appeal, improved functionality, and lighter, more durable components.

Advantages of Micro Etching for Automotive Applications

The micro etching process in Oak Harbor, Ohio, offers numerous advantages for automotive applications. It allows for the creation of intricate and precise patterns on various materials used in vehicle manufacturing. This level of detail can enhance structural integrity, improve performance, and contribute to fuel efficiency. By employing micro etching, manufacturers can achieve complex geometries that would be difficult or impossible to produce with traditional machining methods.

One of the key benefits is its ability to create lightweight components while maintaining strength. This is particularly valuable in the automotive industry where reducing vehicle weight to enhance fuel economy is a constant focus. Micro etching also facilitates better material utilization, minimizing waste and associated costs. Its precision ensures consistent quality control, resulting in reliable and durable automotive parts. Additionally, the process can be easily customized for specific part requirements, making it a versatile solution for modern vehicle design and development.

Material Considerations for Micro Etching in Ohio

When considering material choices for micro etching in Oak Harbor, Ohio, it’s crucial to select substances compatible with the intricate and precise nature of this manufacturing process. The benefits of micro etching are manifold, from enhancing part functionality to improving durability and aesthetics. For automotive parts, materials like aluminum, stainless steel, and certain plastics are often preferred due to their versatility and responsiveness to micro etching techniques.

In Ohio, where the micro etching process is highly advanced, these materials can be meticulously shaped and detailed, creating intricate designs and structures at a microscopic level. The benefits extend beyond physical attributes; micro etching also enables better bonding of coatings and adhesives, ensuring longer-lasting performance in harsh automotive environments. This precision-based approach revolutionizes part manufacturing, making vehicles lighter, more efficient, and aesthetically pleasing.

Applications of Micro Etched Automotive Parts

Finding Reliable Micro Etching Services in Oak Harbor

When it comes to finding reliable micro etching services in Oak Harbor, Ohio, there are several factors to consider. The city is home to a growing number of specialized machining and precision manufacturing facilities that offer advanced micro etching capabilities. These businesses cater to a range of industries, including automotive, medical device, and electronics, ensuring top-notch quality and adherence to stringent industry standards.

One of the key benefits of micro etching in Oak Harbor is access to cutting-edge technology and expertise. Local service providers invest heavily in state-of-the-art equipment and continuously train their staff to stay current with the latest advancements in the micro etching process. This commitment to excellence translates into precise, repeatable results, ensuring that automotive parts manufactured through micro etching meet or exceed performance and safety requirements. Whether you need intricate details etched onto components or specialized materials processed, Oak Harbor’s micro etching services offer a reliable and efficient solution tailored to your specific needs.