The renewable energy sector faces a critical safety challenge from arc flashes—powerful electrical discharges with severe consequences. A comprehensive arc flash study process is essential to address this. It involves meticulous electrical hazard analysis using advanced tools to identify and assess arc flash points, risks, and protective equipment needs. Compliance with standards like NFPA 70E or IEC 61508 ensures worker safety throughout the system's lifecycle. This process guides design modifications, improved labeling, training, and enhanced PPE, mitigating arc flash, electrocution, and electrical fire risks. Regular reviews are vital to adapt to changes in technology and regulations. By following these best practices, renewable energy systems can significantly reduce risks associated with arc flashes.

In the rapidly growing renewable energy sector, understanding and mitigating arc flash risk is paramount for worker safety and system reliability. This comprehensive guide delves into the critical aspects of arc flash in renewable energy systems. From grasping the intricacies of the arc flash study process to exploring key components of electrical hazard analysis and uncovering industry standards, we provide a step-by-step approach to risk mitigation. Learn best practices and real-world case studies showcasing effective arc flash prevention strategies, ensuring safer and more efficient renewable energy facilities.

- Understanding Arc Flash Risk in Renewable Energy Systems

- The Arc Flash Study Process: A Step-by-Step Guide

- Key Components of Electrical Hazard Analysis in Renewables

- Uncovering Arc Flash Safety Standards and Compliance

- Best Practices for Mitigating Risks in Renewable Energy Facilities

- Case Studies: Real-World Examples of Arc Flash Prevention

Understanding Arc Flash Risk in Renewable Energy Systems

Understanding Arc Flash Risk in Renewable Energy Systems

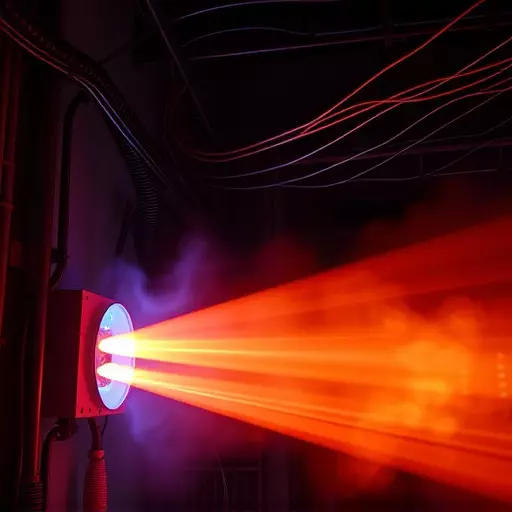

In the rapidly growing renewable energy sector, arc flash risk is an often-overlooked but critical safety concern. An arc flash is a powerful electrical discharge that occurs when there’s a breakdown of insulation between conductive parts, leading to a rapid transfer of electrical energy. This sudden release can cause severe injuries or even fatalities due to the intense heat and pressure waves it generates. To mitigate these risks, a comprehensive arc flash study process is essential, involving detailed assessments of system design, operation, and maintenance procedures.

This study process leverages advanced analysis tools and techniques, such as fault simulation and electrical hazard analysis, to identify potential arc flash hazards across the entire renewable energy system lifecycle. Compliance with established arc flash safety standards, like those set by NFPA 70E or IEC 61508, is crucial. These standards provide guidelines for risk assessment, protective equipment selection, and safe work practices, ensuring that personnel working on or around these systems are protected from potentially deadly electrical hazards.

The Arc Flash Study Process: A Step-by-Step Guide

The Arc Flash Study Process begins with a thorough electrical hazard analysis. This involves identifying all potential arc flash points within the renewable energy system, including but not limited to, switchgear, transformers, and circuit breakers. By employing specialized software and industry-standard calculations, engineers can determine the incident energy at each location, which is crucial for assessing risk levels.

Next, once hazards are identified, the study progresses to evaluating risks associated with these arcs. This step involves considering factors such as probability of occurrence, available protective equipment (PPE), and potential consequences. Based on this risk assessment, appropriate arc flash safety standards can be implemented. These may include modification to system design, improved labeling and signage, employee training, and the introduction of enhanced PPE.

Key Components of Electrical Hazard Analysis in Renewables

The arc flash study process is a critical component of electrical hazard analysis in renewable energy systems. It involves identifying potential sources of electrical arcs, evaluating their energy release, and determining the appropriate protective measures. This process leverages advanced calculations, simulations, and risk assessment tools to create a comprehensive understanding of the system’s arc flash hazards. By analyzing factors like equipment ratings, fault currents, and clearance distances, professionals can pinpoint areas requiring enhanced safety measures, such as personal protective equipment (PPE), grounding systems, and surge protection devices.

Adherence to arc flash safety standards is paramount in renewable energy sectors. International standards like NFPA 70E and IEC 61508 provide guidelines for electrical hazard analysis, risk assessment, and mitigation strategies. These standards ensure that the electrical hazard analysis considers not just arc flash but also other electrical risks, including electrocution and electrical fires. Regular reviews and updates of these analyses are essential to account for system changes, technological advancements, and evolving safety regulations, thereby fostering a safer working environment for personnel interacting with renewable energy systems.

Uncovering Arc Flash Safety Standards and Compliance

In the renewable energy sector, understanding and adhering to arc flash safety standards is paramount. The arc flash study process involves a comprehensive electrical hazard analysis that identifies potential risks associated with equipment and systems. This meticulous analysis evaluates factors such as voltage, current, and arcing time to determine the energy released during an arc flash event. By employing advanced calculations and simulations, professionals can assess the likelihood and severity of such incidents, enabling them to implement appropriate safety measures.

Compliance with arc flash safety standards is not just a regulatory requirement but also a critical step in ensuring the well-being of workers and the reliability of renewable energy systems. These standards provide guidelines for safe work practices, personal protective equipment (PPE) selection, and system design modifications. Regular audits and training sessions further reinforce compliance, ensuring that all stakeholders are equipped to recognize and mitigate arc flash hazards effectively.

Best Practices for Mitigating Risks in Renewable Energy Facilities

In mitigating risks associated with arc flash in renewable energy systems, a structured approach is essential. The initial step involves conducting an arc flash study process, which includes a thorough electrical hazard analysis. This comprehensive evaluation identifies potential arc flash points and quantifies associated risks, guiding the implementation of appropriate safety measures.

Best practices dictate adhering to established arc flash safety standards, such as those provided by IEC 61508 or NFPA 70E. These standards offer guidelines for risk assessment, protective equipment selection, and training protocols, ensuring a safe working environment during installation, maintenance, and operation of renewable energy facilities. Regular reviews and updates of these measures are crucial to adapt to the evolving nature of technology and safety regulations.

Case Studies: Real-World Examples of Arc Flash Prevention

Arc flash risks are prevalent in renewable energy systems due to their complex electrical architectures. To mitigate these dangers, numerous arc flash study processes have been implemented across various case studies. These real-world examples demonstrate the importance of a systematic approach to electrical hazard analysis. By employing advanced simulation tools and adhering to arc flash safety standards, engineers can identify potential arc flash events and implement targeted preventive measures.

One notable arc flash study process involved a wind farm where a comprehensive assessment revealed multiple high-risk zones. Through detailed circuit analysis and risk categorization, the team identified critical components prone to arcing. Subsequent interventions included upgrading protective devices, installing enhanced shielding, and implementing remote monitoring systems. These measures significantly reduced the likelihood of catastrophic failures, underscoring the effectiveness of a data-driven arc flash prevention strategy.