Industrial ventilation solutions play a pivotal role in controlling dust and particulate matter within manufacturing environments. These solutions, encompassing both supply and exhaust systems, are designed to ensure worker health, enhance productivity, and comply with safety regulations by maintaining optimal air quality. Exhaust systems capture and remove contaminants at their source, preventing the spread of fumes, pollutants, and harmful particulates, while supply systems introduce clean, conditioned air to improve comfort and performance. The integration of advanced filtration technologies like HEPA filters and electrostatic precipitators in these systems has significantly improved their efficiency in addressing various types of dust, reducing respiratory risks, and preserving equipment integrity. Recent technological advancements have further optimized these ventilation solutions, contributing to environmental benefits by decreasing air pollution and enabling smart controls for real-time adjustments in performance. Across different industries, such as woodworking, pharmaceuticals, and food processing, these systems have successfully mitigated specific environmental challenges, ensuring safe and productive workspaces while upholding high standards of health and safety. Keywords: industrial ventilation solutions, exhaust ventilation solutions, supply ventilation systems.

Dust collection systems play a pivotal role in maintaining safe and productive industrial environments. This article delves into their critical function within the manufacturing sector, offering insights into the components of effective industrial ventilation solutions, including exhaust and supply ventilation systems. We explore the importance of these systems in safeguarding worker health and protecting against combustible dust fires and explosions. Advanced technologies in dust collection are also examined for their contributions to improved air quality, with real-world case studies highlighting successful implementations across various industries. Join us as we navigate the essential aspects of industrial ventilation solutions that contribute to a cleaner, safer, and more efficient workplace.

- Understanding the Role of Dust Collection Systems in Industrial Settings

- Components of Effective Industrial Ventilation Solutions

- The Importance of Exhaust Ventilation in Maintaining Safe Work Environments

- Design Considerations for Supply Ventilation Systems in Manufacturing Facilities

- Advanced Technologies in Dust Collection and Their Impact on Air Quality

- Case Studies: Successful Implementation of Dust Collection Systems Across Industries

Understanding the Role of Dust Collection Systems in Industrial Settings

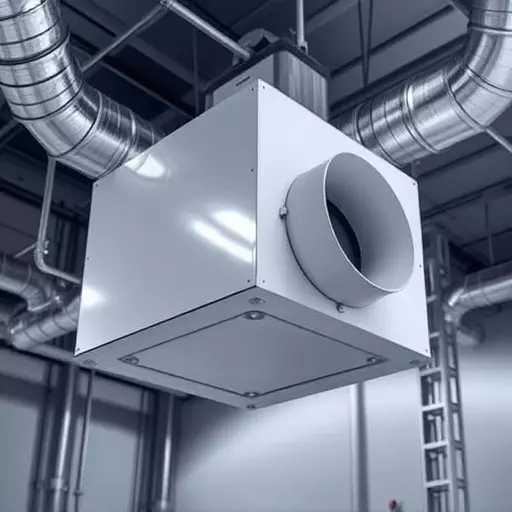

Industrial settings often generate large volumes of dust and airborne particulate matter during manufacturing processes. This byproduct can pose significant health risks to workers and compromise product quality. Moreover, excessive dust accumulation can lead to machinery malfunctions, reduced operational efficiency, and increased fire hazards. To mitigate these risks, industrial ventilation solutions play a pivotal role. These systems are specifically designed to capture and remove particulate matter from the air effectively. They integrate supply and exhaust ventilation systems to ensure a continuous flow of clean air within the facility, thus maintaining a safe and productive environment. The supply system introduces fresh air, while the exhaust system is responsible for capturing dust at the source and conveying it to central collection points. By doing so, these ventilation solutions prevent dust from circulating and becoming airborne again. This proactive approach not only protects workers but also extends the lifespan of equipment by keeping components free of dust buildup. Furthermore, compliance with occupational safety and health regulations is facilitated, and overall operational costs are reduced over time due to improved equipment performance and longevity.

Components of Effective Industrial Ventilation Solutions

Industrial ventilation solutions play a pivotal role in maintaining a safe and healthy work environment by controlling the quality of air in industrial settings. Effective industrial ventilation encompasses both exhaust and supply ventilation systems working in tandem to ensure optimal airflow. Exhaust ventilation solutions are designed to remove contaminants, pollutants, fumes, and vapors from the workspace, capturing harmful particulates at their source or through local exhaust hoods and ducts. These systems are critical for compliance with occupational safety and health regulations and for protecting workers’ respiratory health.

On the flip side, supply ventilation systems deliver fresh, conditioned air to ensure worker comfort and productivity. Adequate airflow is essential to prevent the accumulation of heat, chemicals, or dust that can lead to overexposure and hazardous working conditions. The integration of both exhaust and supply systems within a comprehensive industrial ventilation solution creates a balanced environment, effectively controlling pollutants and maintaining air quality. Key components such as air filters, dampers, fans, and air handling units are integral to the functionality and performance of these systems. Additionally, the selection of appropriate materials for ductwork, the inclusion of monitoring equipment, and the design for minimal leakage are essential factors in creating a robust industrial ventilation solution that protects workers and adheres to environmental standards.

The Importance of Exhaust Ventilation in Maintaining Safe Work Environments

In industries where dust and particulate matter are generated during manufacturing processes, the implementation of effective industrial ventilation solutions is paramount to ensure the safety and health of workers. Exhaust ventilation systems play a crucial role in capturing hazardous airborne contaminants at their source before they disperse throughout the work environment. These systems are designed to draw the contaminated air directly from its point of generation, effectively removing it from the workspace and directing it outside or through filtration systems. This proactive approach to air quality management minimizes worker exposure to potentially harmful dusts, which can mitigate the risk of respiratory issues, fire hazards, and explosions that dust can facilitate.

Furthermore, the integration of comprehensive exhaust ventilation solutions as part of an industrial facility’s ventilation strategy not only protects workers but also enhances overall productivity and equipment longevity. By maintaining clean air within production areas, these systems prevent the accumulation of dust on machinery and work surfaces, which can otherwise lead to malfunctions and costly downtimes. Supplementing exhaust ventilation with appropriate supply ventilation systems ensures a balanced airflow within the facility, providing comfortable working conditions that are conducive to optimal performance and reducing the frequency of maintenance required for both the HVAC system and the production equipment. This holistic approach to industrial ventilation is essential for maintaining safe and efficient work environments in manufacturing settings.

Design Considerations for Supply Ventilation Systems in Manufacturing Facilities

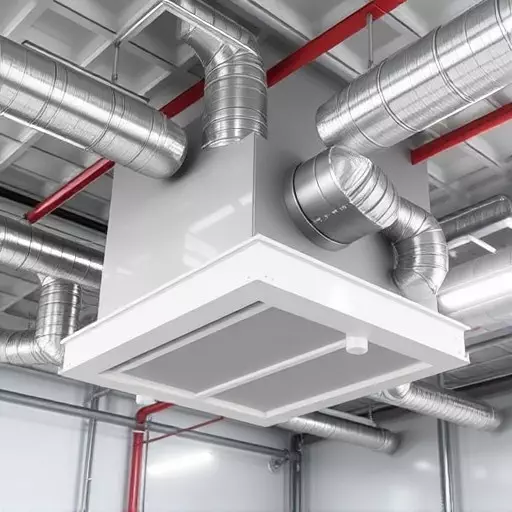

In manufacturing facilities, ensuring a safe and healthy work environment is paramount. The design of supply ventilation systems plays a crucial role in this endeavor by delivering clean air to occupied spaces. These industrial ventilation solutions must be tailored to the specific needs of each facility, taking into account factors such as the types of materials being processed, the volume of air required to maintain adequate air exchange rates, and the potential for airborne contaminants. The supply systems should be strategically placed to distribute fresh air evenly throughout the facility, minimizing the concentration of pollutants and preventing stagnation. High-efficiency particulate air (HEPA) filters can be integrated into these systems to enhance air quality further.

When integrating exhaust ventilation solutions, it is equally important to consider how they will complement the supply systems. A well-designed exhaust system works in tandem with the supply system to maintain optimal indoor air quality. It captures and removes contaminants at the source, reducing the overall load on the supply side. The integration of both systems should be done with consideration for airflow patterns, pressure differentials, and filtration efficiency to ensure that the air supplied is not immediately compromised by exhaust from processes or machinery. Additionally, these ventilation solutions must comply with occupational safety and health regulations, ensuring that workers are protected against hazardous fumes, dust, and particulate matter. By meticulously planning and implementing industrial ventilation solutions, manufacturers can create a safer and more productive environment for their employees.

Advanced Technologies in Dust Collection and Their Impact on Air Quality

In recent years, the integration of advanced technologies in dust collection systems has significantly enhanced the efficiency and effectiveness of industrial ventilation solutions. These sophisticated systems are designed to capture and remove dust particles from the air, ensuring a safer and healthier environment for workers and surrounding communities. The use of high-efficiency particulate air (HEPA) filters, for instance, is pivotal in capturing microscopic dust particles, thereby reducing the risk of respiratory issues. Additionally, the incorporation of electrostatic precipitators has proven to be an effective method for charging and collecting charged dust particles, which traditional filters may miss. These advancements not only protect air quality but also contribute to the longevity of the equipment by preventing dust accumulation, thereby reducing maintenance costs and downtime.

The impact of these exhaust ventilation solutions extends beyond occupational health; they also play a critical role in environmental stewardship. By employing sophisticated filtration systems and advanced monitoring technologies, industries can significantly reduce emissions that contribute to air pollution. Furthermore, the integration of smart controls and automation allows for real-time adjustments to dust collection performance, ensuring optimal airflow and filtration efficiency. Supply ventilation systems complement these efforts by providing controlled airflow to reduce the concentration of hazardous substances at their source, thus creating a healthier working environment and minimizing the environmental footprint of industrial processes. These advancements underscore the importance of investing in modern dust collection technologies as part of comprehensive industrial ventilation strategies.

Case Studies: Successful Implementation of Dust Collection Systems Across Industries

Across various industries, the implementation of effective dust collection systems has proven to be a cornerstone in maintaining safe and productive work environments. For instance, in the woodworking sector, companies have significantly improved air quality by integrating industrial ventilation solutions tailored to capture fine wood dust. These systems not only enhance worker comfort but also comply with stringent occupational health and safety standards. The integration of advanced filtration technologies ensures that the extracted particles are efficiently removed, reducing the risk of respiratory issues and fire hazards. Similarly, in the manufacturing of pharmaceuticals, where cleanroom environments are paramount, exhaust ventilation solutions are meticulously designed to maintain sterile conditions by eliminating airborne contaminants. The implementation of these systems has led to a marked decrease in product recalls and contamination incidents, underscoring their critical role in maintaining high-quality standards. Furthermore, the food processing industry has also benefited from supply ventilation systems that are specifically engineered to handle the unique challenges posed by organic dust and moisture. These systems maintain optimal indoor air quality, preventing cross-contamination and ensuring product safety, which is essential for consumer protection and brand reputation. The success stories across these diverse sectors demonstrate the versatility and effectiveness of supply and exhaust ventilation solutions in safeguarding operational integrity and workforce health.