Holland and Ohio lead the way in providing top-tier protective foam inserts specifically designed to safeguard automotive electronic components during transportation. These custom foam inserts are meticulously crafted using ESD-safe materials to prevent electrostatic discharge and offer robust protection against physical impacts, ensuring that sensitive electronics arrive intact and functional. The precision engineering of these foam inserts is tailored to fit each component perfectly, providing superior shock absorption and anti-static properties. This commitment to advanced packaging solutions with custom foam inserts sets a new industry benchmark for the automotive sector, emphasizing a dedication to excellence and reliability, particularly important given the increasing complexity of electronic systems within vehicles. The integration of CNC machining technology ensures that these protective solutions meet the high standards required by modern supply chain demands, underscoring Holland and Ohio's position as leaders in anti-static foam innovation for electronics. Keywords: protective foam inserts for electronics holland ohio, custom foam inserts, ESD-safe foam inserts, anti-static foam for electronics.

In the fast-paced world of automotive manufacturing and distribution, the integrity of advanced electronics is paramount. As such, the role of precision engineering in creating protective foam inserts for electronics in Holland and Ohio has become increasingly vital. This article delves into the advancements in CNC machining that have led to the development of custom foam inserts, a pivotal component in safeguarding these sophisticated components during transit and storage. From the importance of ESD-safe foam inserts to innovative anti-static foam solutions, we explore how these technologies not only protect against electronic interference but also streamline the automotive supply chain. The focus on Holland and Ohio underscores the region’s commitment to excellence in automotive packaging, ensuring that every electronic device reaches its destination intact and operational.

- Maximizing Automotive Electronics Protection with Custom Foam Inserts in Holland and Ohio

- The Role of Protective Foam Inserts for Electronics in Automotive Packaging Solutions

- Electronic Shielding Through ESD-Safe Foam Inserts: A Key Component in Automotive Packaging

- Innovative Anti-Static Foam for Electronics: Ensuring Safety and Performance in Automotive Applications

- Streamlining the Automotive Supply Chain with Advanced Foam Insert Solutions in Holland and Ohio

Maximizing Automotive Electronics Protection with Custom Foam Inserts in Holland and Ohio

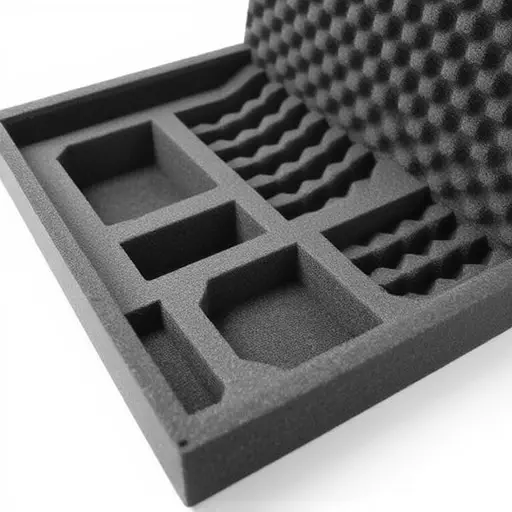

In the realm of automotive electronics, ensuring the protection of components during transportation and storage is paramount. Holland and Ohio have become synonymous with precision and care in the handling of such sensitive materials, leveraging their expertise to provide solutions that safeguard against potential damage. Custom foam inserts for electronics are a testament to this commitment, offering tailored fits for each unique component. These protective foam inserts, crafted specifically for Holland and Ohio, are designed to conform perfectly to the shapes of automotive electronic parts, providing them with unparalleled support and shock absorption during transit. The use of ESD-safe foam inserts is particularly crucial in preventing electrostatic discharge that could compromise the delicate circuitry within these devices. This anti-static foam for electronics not only secures the components but also maintains their functional integrity by preserving sensitive electrical properties. The result is a significantly reduced risk of damage, ensuring that when automotive electronics arrive at their destination, they are ready for integration without delay or additional repairs. The precision and customization offered by these foam inserts in Holland and Ohio are setting new standards for the automotive industry, demonstrating a dedication to excellence and reliability in packaging solutions.

The Role of Protective Foam Inserts for Electronics in Automotive Packaging Solutions

In the realm of automotive packaging solutions, the protection of electronic components during transit and handling is paramount. Protective foam inserts for electronics, crafted by manufacturers like those in Holland, Ohio, serve as a critical layer of defense against potential impacts and environmental factors. These custom foam inserts are engineered to fit precisely within the automotive packaging design, ensuring that every contour and crevice of delicate electronic parts is cushioned against shock and vibration. The significance of these inserts is underscored when considering their role in maintaining the integrity of sophisticated automotive electronics, which are integral to modern vehicles’ performance and safety systems.

Moreover, the advent of electronics requiring ESD-safe (Electrostatic Discharge) foam inserts has revolutionized the way electronic components are protected within the automotive industry. Anti-static foam for electronics is specifically designed to neutralize static electricity, thereby preventing damage to sensitive components caused by electrostatic discharge. This advanced material not only protects against physical impacts but also safeguards against the subtle dangers of electromagnetic interference and static charge accumulation. The integration of these ESD-safe foam inserts into automotive packaging solutions is a testament to the industry’s commitment to maintaining the highest standards of electronic component protection, ensuring that each part arrives at its destination intact and functional.

Electronic Shielding Through ESD-Safe Foam Inserts: A Key Component in Automotive Packaging

In the realm of automotive packaging, the integrity and safety of electronic components are paramount. As vehicles become increasingly sophisticated with advanced driver-assistance systems and electric powertrains, the need for robust protective measures has grown. One critical component in safeguarding these electronics during transport is the use of specialized foam inserts designed by providers in Holland, Ohio, and beyond. These custom foam inserts are engineered to provide superior protection against shocks, vibrations, and environmental factors that could potentially damage delicate electronic parts. The integration of ESD-safe foam inserts is particularly crucial, as they offer a protective shield against electrostatic discharge (ESD), which can otherwise wreak havoc on sensitive electronic circuits. The anti-static properties of these foam inserts ensure that static electricity is dissipated harmlessly, thereby preventing the formation of harmful charges that could lead to component failure or malfunction. This not only safeguards the electronics but also guarantees the functionality and performance of the automotive systems upon arrival at their destination.

The selection of the right foam material for ESD-safe applications is a complex task that requires expertise in both materials science and electronic engineering. Manufacturers specializing in custom foam inserts, such as those in Holland, Ohio, leverage cutting-edge technology to create tailor-made solutions that cater to the specific needs of each automotive client. The advanced ESD-safe foam inserts are designed with precision and manufactured under strict quality control to ensure consistent performance. These innovative solutions are not only lightweight and cost-effective but also demonstrate a commitment to excellence and reliability, which is essential for the high-stakes environment of automotive electronics packaging. With the increasing complexity of automotive systems, the demand for such protective measures will only continue to rise, making ESD-safe foam inserts an indispensable element in the supply chain of the automotive industry.

Innovative Anti-Static Foam for Electronics: Ensuring Safety and Performance in Automotive Applications

CNC machining has become a cornerstone in the production of specialized components, such as protective foam inserts for electronics in automotive packaging. Holland, Ohio, stands out as a pivotal location for manufacturers who prioritize precision and quality in their custom foam inserts. These advanced foam solutions are not just any cushioning material; they are ESD-safe foam inserts designed to safeguard delicate electronic components from electrostatic discharge (ESD). The integrity of electronics within automotive systems is paramount, and the advent of anti-static foam for electronics has revolutionized how these components are packaged and transported. The customizable nature of these foam inserts allows for a perfect fit for each electronic part, ensuring that every device arrives at its destination intact and operational.

The precision engineering behind CNC machining enables the creation of complex geometries with tight tolerances that are essential for anti-static foam applications. These foam inserts are tailored to meet rigorous standards set by the automotive industry, where reliability and functionality are non-negotiable. The anti-static properties inherent in these foams prevent static accumulation, which could otherwise compromise the sensitive electronics within vehicles. By leveraging the capabilities of CNC machining, manufacturers in Holland, Ohio, can produce high-quality custom foam inserts that not only protect against ESD but also conform to the unique shapes and sizes of modern automotive electronic components. This ensures that when these components are installed in vehicles, they perform optimally, enhancing the overall safety and reliability of the automobile.

Streamlining the Automotive Supply Chain with Advanced Foam Insert Solutions in Holland and Ohio

In the realm of automotive packaging, streamlining the supply chain is paramount to maintaining efficiency and ensuring timely delivery of components. Advanced foam insert solutions in Holland and Ohio play a pivotal role in this process. Manufacturers in these regions leverage cutting-edge technology to design custom foam inserts that cater specifically to the needs of the automotive industry. These protective foam inserts for electronics, crafted with precision by experts in Holland and Ohio, are tailored to fit a variety of electronic components, providing them with the necessary cushioning against impact and vibration during transit. The custom foam inserts not only safeguard the delicate elements within but also facilitate the quick sorting and handling of parts, which is essential for just-in-time manufacturing strategies.

Moreover, the innovative solutions extend beyond conventional protective measures. ESD-safe foam inserts are a critical component in these regions, given their anti-static properties that protect sensitive electronics from electrostatic discharge (ESD). The demand for anti-static foam for electronics is growing, particularly within the automotive sector where electronic systems are increasingly integrated into vehicles. The expertise of Holland and Ohio’s manufacturers ensures that these ESD-safe solutions are designed to meet rigorous industry standards, guaranteeing the integrity of the components and reducing the risk of damage or failure due to static charge accumulation. This commitment to advanced foam insert technology is a testament to the regions’ dedication to excellence in automotive packaging, directly contributing to the streamlining of the supply chain and the protection of high-value electronics.