Custom automotive foam inserts in Holland, Ohio, are transforming shipping protection for delicate and heavy-duty car parts. These specialized padding materials safeguard components by absorbing shock, preventing damage, and ensuring intact delivery. From electronics to machinery, the tailored designs encapsulate and secure parts, reducing financial losses for businesses while enhancing product reliability and customer satisfaction.

“In the world of automotive manufacturing and shipping, ensuring the safe arrival of heavy-duty parts is paramount. This is where custom automotive foam inserts step in as unsung heroes. These specialized padding solutions are designed to protect delicate components during transit, minimizing damage and ensuring quality retention.

This article explores the significance of foam pads in automotive shipping, delving into customization options for specific parts and highlighting their diverse applications in Holland, Ohio.”

- Understanding the Importance of Foam Pads in Automotive Shipping

- Customization: Creating Inserts for Specific Fragile Parts

- Benefits and Applications of Automotive Foam Inserts in Holland, Ohio

Understanding the Importance of Foam Pads in Automotive Shipping

In the world of automotive manufacturing and shipping, protecting delicate components during transit is paramount. This is where custom automotive foam inserts step in as unsung heroes. These specialized padding solutions are designed to safeguard fragile parts, ensuring they reach their destination intact. For example, in Holland, Ohio, automotive foam inserts for shipping have become a game-changer for local manufacturers and logistics providers.

By employing custom foam inserts tailored to specific part dimensions, companies can prevent damage caused by shifting during transportation. These foam pads act as a protective barrier, absorbing shock and vibrations, and thus, reducing the risk of breakage. This is particularly crucial for valuable and intricate automotive parts, where even minor damage can lead to significant financial losses. Thus, investing in high-quality foam inserts demonstrates a commitment to preserving the integrity of automotive components during their journey from production line to end user.

Customization: Creating Inserts for Specific Fragile Parts

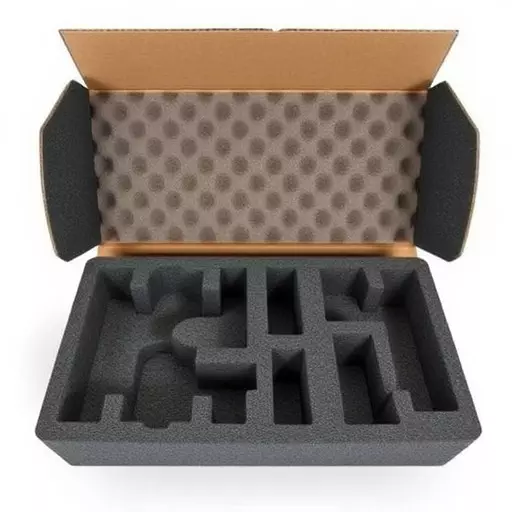

Customizing foam padding to fit specific fragile automotive parts is a specialized service offered by many suppliers in Holland, Ohio. This tailored approach ensures that delicate components receive the utmost protection during shipping and handling. By creating custom automotive foam inserts, businesses can accommodate unique shapes and sizes, providing a snug fit for each part. This customization goes beyond standard off-the-shelf solutions, offering enhanced security for high-value or vulnerable items.

Automotive foam inserts are designed to absorb shock and prevent damage, making them indispensable for parts shipping. Customization allows for precise alignment and support, reducing the risk of movement during transit. Whether it’s a rare vintage component or a modern, complex assembly, these specialized inserts can be crafted to meet exacting requirements. This level of customization is particularly beneficial for businesses dealing in specialized automotive parts, ensuring they maintain high-quality standards and protect their products’ integrity.

Benefits and Applications of Automotive Foam Inserts in Holland, Ohio

In Holland, Ohio, automotive foam inserts have emerged as a game-changer in protecting and shipping heavy-duty and fragile automotive parts. These custom foam solutions offer unparalleled benefits, ensuring that components reach their destinations intact and undamaged. By encapsulating and securing parts within a soft yet robust matrix, foam inserts minimize the risk of cracks, dents, or other forms of damage during transit—a significant concern for auto manufacturers and repair shops alike.

Applications range from delicate electronic assemblies to heavy machinery, where the insulative properties of foam help maintain part integrity while reducing shipping costs. Custom-designed automotive foam inserts allow for precise fitting around complex shapes, maximizing protection and space utilization. This is especially valuable in the competitive Ohio market, where efficient logistics and high-quality components are paramount. For businesses in Holland and beyond, leveraging these innovative foam solutions means enhanced product reliability, cost savings, and improved customer satisfaction.