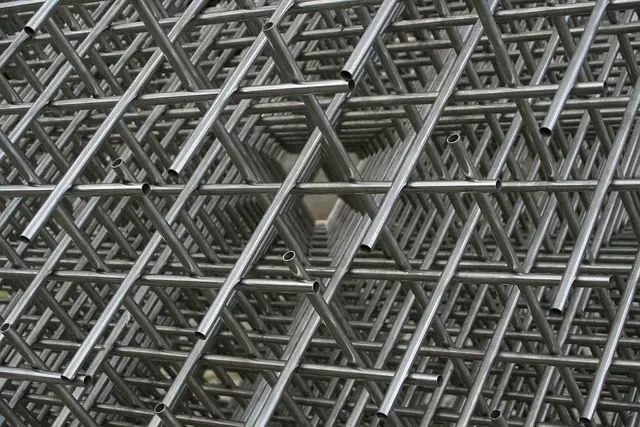

Steel packaging solutions represent a sustainable, cost-effective choice for modern industry, offering durable and recyclable alternatives that align with economic sustainability and environmental conservation. These solutions are tailored to various industries, from cosmetics to food and beverage, providing robust containers that protect products throughout the supply chain without compromising on quality or safety. The high recyclability of steel means it can be repurposed indefinitely without loss of quality, significantly reducing waste management costs and carbon emissions compared to other materials. Custom designs in steel packaging can be optimized for efficiency to minimize costs while maximizing sustainability, ensuring that companies benefit from both economic advantages and a stronger eco-conscious brand image. As the industry evolves with sustainability at its core, steel packaging solutions remain adaptable, promising long-term viability for businesses looking to future-proof their operations and maintain environmentally responsible practices.

Steel packaging solutions have emerged as a pivotal element in modern industrial practices, offering a blend of durability and sustainability. This article delves into the multifaceted aspects of steel packaging, examining its economic influence, sustainable credentials, and cost-efficiency for businesses. We explore the material’s selection impact on pricing and perform a thorough lifecycle cost analysis relative to other materials. Additionally, we assess how scale, volume, and design complexity affect production costs, and scrutinize the long-term investment potential of custom steel packaging solutions. Key insights are provided to guide companies in making informed decisions about their packaging strategies.

- Understanding the Economic Impact of Steel Packaging Solutions in Modern Industries

- The Role of Sustainable Steel Packaging in Eco-Friendly Manufacturing Practices

- Cost-Benefit Analysis of Adopting Custom Steel Packaging Options for Businesses

- Material Selection and its Implications on the Price Structure of Steel Packaging Solutions

- Analyzing the Lifecycle Costs of Steel Packaging versus Other Materials

- The Impact of Scale, Volume, and Design Complexity on Steel Packaging Production Costs

- Long-Term Investment: The Return on Scalability and Innovation in Custom Steel Packaging Solutions

Understanding the Economic Impact of Steel Packaging Solutions in Modern Industries

Steel packaging solutions play a pivotal role in shaping the economic landscape of modern industries, offering sustainable and cost-effective options for product containment and distribution. The adoption of these solutions has been influenced by the growing global focus on sustainability and the environmental impact of packaging materials. Sustainable steel packaging emerges as a frontrunner due to its high recyclability, durability, and ability to protect products over long distances without compromising integrity. Unlike other packaging materials that may degrade or contribute to landfill issues, steel packaging can be repeatedly recycled indefinitely without loss of quality, thus significantly reducing the carbon footprint associated with packaging production and disposal.

Custom steel packaging solutions further enhance their economic viability by catering to diverse industry needs, from aerosol cans for cosmetics to containers for food and beverages, and even industrial components. These tailored options enable businesses to optimize packaging design for both product protection and brand promotion, leading to reduced waste and increased market competitiveness. The cost analysis of steel packaging reveals its long-term economic advantages, as the initial investment is often offset by lower transportation costs, reduced product damage during transit, and the ability to tap into recycling streams that can offset material costs over time. This not only contributes to the sustainability goals of companies but also presents a compelling business case for industries looking to innovate and differentiate themselves in a crowded marketplace.

The Role of Sustainable Steel Packaging in Eco-Friendly Manufacturing Practices

Steel packaging solutions play a pivotal role in advancing eco-friendly manufacturing practices, offering a sustainable alternative to traditional packaging materials. The adoption of sustainable steel packaging not only reduces environmental impact but also aligns with modern sustainability goals. Steel’s inherent properties—such as its recyclability, durability, and strength—make it an ideal candidate for packaging applications, ensuring products are protected during transport while minimizing the carbon footprint associated with packaging production and disposal. Custom steel packaging solutions, tailored to specific product needs, further enhance the versatility of this material. These custom options allow manufacturers to design packaging that fits perfectly, reducing waste and improving resource efficiency. The lifecycle analysis of steel packaging reveals its superiority over other materials; it is infinitely recyclable without loss of quality, meaning it can be reused repeatedly without contributing to landfill waste. This characteristic, coupled with the energy-intensive processes required to produce alternative packaging materials, underscores the environmental advantages of sustainable steel packaging. By integrating these solutions into manufacturing practices, companies can demonstrate a commitment to sustainability and contribute to a circular economy, all while maintaining the integrity and safety of their products throughout the supply chain.

Cost-Benefit Analysis of Adopting Custom Steel Packaging Options for Businesses

In the realm of business operations, the adoption of custom steel packaging solutions presents a compelling cost-benefit analysis for companies seeking to optimize their resource management and sustainability efforts. Steel, inherently durable and recyclable, stands out as a sustainable choice among packaging materials. Its longevity not only reduces the frequency of replacement but also minimizes the environmental impact associated with packaging waste. Custom steel packaging options can be tailored to fit specific product needs, offering enhanced protection during transportation and storage, thereby reducing spoilage and associated financial losses. These solutions are engineered for efficiency, often allowing for automated filling and handling, which can lead to significant reductions in labor costs over time. Furthermore, the initial investment in custom steel packaging is often offset by its long-term durability and recyclability, a factor that can significantly lower the total cost of ownership when compared to other less sustainable packaging options. Companies that opt for these sustainable steel packaging solutions can position themselves as environmentally responsible entities, potentially enhancing their brand image and customer loyalty in an increasingly eco-conscious marketplace.

The transition to custom steel packaging is a strategic move that aligns with the global shift towards more sustainable materials. It not only addresses cost concerns but also contributes to corporate sustainability goals. The versatility of steel allows for various designs and sizes, ensuring that each package meets the unique demands of its contents. This specificity in design can lead to reduced material usage without compromising on performance, another aspect that positively impacts the bottom line. Additionally, the energy-intensive process of recycling steel packaging is offset by its ability to be repurposed multiple times without loss of integrity. This resilience against degradation ensures that the investment in custom steel packaging retains its value over an extended period, offering a return on investment that is both financially and environmentally sound. As businesses increasingly evaluate the long-term sustainability and cost efficiency of their operations, the role of custom steel packaging as a viable option becomes ever more apparent.

Material Selection and its Implications on the Price Structure of Steel Packaging Solutions

In the realm of product packaging, steel stands out as a material that offers both durability and sustainability, influencing the price structure of steel packaging solutions significantly. The selection of steel as a packaging material is influenced by its robustness and recyclability, which aligns with contemporary environmental concerns. Steel’s ability to be recycled indefinitely without loss of quality positions it as a sustainable choice, reducing both production and disposal costs. This eco-friendly attribute often justifies a higher upfront cost compared to less sustainable materials. Custom steel packaging solutions further complicate the price structure, as they require tailored designs and specialized manufacturing processes that increase production complexity and cost. However, these custom options can offer superior protection for products, reducing damage during transport and extending shelf life, which can be offsetting factors in the total cost of ownership. The design and engineering stages are critical in determining the final price tag; innovations that streamline the process or utilize scrap steel more efficiently can lead to cost savings, making sustainable steel packaging a competitive option in various industries. Companies exploring steel packaging solutions must weigh the initial investment against the long-term environmental and economic benefits, ensuring they consider both the immediate costs and the potential for reduced waste management expenses in the future.

Analyzing the Lifecycle Costs of Steel Packaging versus Other Materials

In evaluating the economic viability of steel packaging solutions over their lifecycle, it’s crucial to consider the broader environmental and cost implications. Steel packaging offers a sustainable alternative to other materials, with its high recycling rate and durability. The initial investment in custom steel packaging may be higher than some competing materials, but this is often offset by lower maintenance costs and a longer usable lifespan. Over time, steel’s resilience against environmental factors such as moisture and temperature extremes reduces the frequency of replacements, thereby cutting long-term expenses significantly. Furthermore, the energy-intensive nature of producing new packaging materials can be mitigated by steel’s ability to be recycled repeatedly without loss of quality. This sustainability aspect not only contributes to a reduced carbon footprint but also translates into cost savings when considering the entire lifecycle of the packaging.

When juxtaposing steel packaging solutions against other materials, it becomes evident that while initial costs might be higher, the total cost of ownership for steel is competitive. The material’s longevity and resistance to damage during transport mean fewer instances of loss or spoilage, a common issue with less durable options. Additionally, the ease of recycling steel containers contributes to a lower environmental impact, aligning with modern sustainability goals. Companies adopting sustainable steel packaging are thus not only investing in a cost-effective solution but also positioning themselves as environmentally responsible entities within their industry. This strategic approach can lead to long-term cost savings and potential for brand differentiation in the marketplace.

The Impact of Scale, Volume, and Design Complexity on Steel Packaging Production Costs

Steel packaging solutions incur varying production costs that are significantly influenced by scale, volume, and design complexity. Larger production scales offer economies of size, where fixed costs are spread over more units, reducing the cost per unit. Companies that operate at high volumes can leverage these efficiencies, making their steel packaging solutions more competitive in price. Conversely, smaller batch sizes or intricate designs can increase costs due to the higher setup times and material usage required for customization.

In the realm of sustainable steel packaging, design complexity becomes a critical factor. Simpler designs not only facilitate easier manufacturing processes but also enhance the recyclability of the packaging. Custom steel packaging with complex geometries may require additional resources to separate components during the recycling process, which can increase costs and potentially reduce the environmental benefits of choosing steel as a sustainable material. Therefore, when considering custom steel packaging options, it is prudent to balance design intricacy with production efficiency to optimize both cost-effectiveness and sustainability.

Long-Term Investment: The Return on Scalability and Innovation in Custom Steel Packaging Solutions

In the realm of industrial packaging, scalability and innovation are pivotal drivers of long-term investment success. Companies that adopt custom steel packaging solutions are often at the forefront of sustainability and efficiency, reaping both environmental and economic benefits. Steel, as a material, offers unparalleled durability and recyclability, making it an ideal choice for businesses aiming to reduce their carbon footprint while ensuring product safety and integrity. Investing in scalable steel packaging solutions allows companies to adjust production levels according to demand fluctuations, thus optimizing resource utilization and reducing waste. Moreover, the adoption of sustainable steel packaging not only aligns with eco-conscious consumer trends but also positions a company as a responsible corporate citizen. This proactive stance can enhance brand reputation and customer loyalty, ultimately translating into a competitive edge in the marketplace. As industries evolve to meet sustainability goals, custom steel packaging solutions remain a cost-effective and scalable option that can adapt to changing needs without compromising on quality or environmental considerations. By continuously innovating and integrating advanced technologies, these solutions ensure that businesses can maintain a strong foothold in the market, offering products that are both economically viable and environmentally sound over the long term.