Holland, Ohio, has become a leading innovator in the heavy-duty container logistics industry, renowned for its top-tier custom injection molded packaging solutions provided by professional injection molding services. These packages offer significant advantages over traditional options, including enhanced durability, improved stacking efficiency, optimized space usage, and better weight distribution, all critical for maintaining the structural integrity of containers during transit. The region's centralized location within a vast transportation network further underscores its significance in logistics, ensuring that goods are transported safely and efficiently. The customizable nature of these packages precisely meets the unique needs of heavy-duty transport, streamlining operations and significantly reducing the risk of costly damages or delays. By adopting injection molded packaging solutions, businesses can enhance their supply chain efficiency, expedite turnaround times, and improve logistics effectiveness, while also positioning themselves favorably in global competition. The strategic use of these advanced packaging options from Holland, Ohio, has set a new industry benchmark, demonstrating the transformative impact on reducing costs and enhancing product protection throughout the entire supply chain network.

navigating the intricate landscape of heavy-duty container logistics is a complex endeavor that demands innovative solutions. This article delves into the challenges and benefits within this sector, emphasizing the role of custom injection molded packaging from Holland, Ohio, as a key strategic advantage. We explore how professional injection molding services not only enhance efficiency and durability in supply chain operations but also provide tailored solutions to overcome logistical hurdles. Through a case study, we illustrate the tangible impact these custom solutions have had in streamlining logistics processes, underscoring their value in the industry.

- Navigating Complexities: The Role of Custom Injection Molded Packaging in Heavy-Duty Container Logistics

- Efficiency and Durability: Advantages of Injection Molded Containers in Supply Chain Operations

- Strategies to Overcome Obstacles in Container Logistics with Professional Injection Molding Services

- Case Study: Streamlining Logistics with Custom Solutions from Holland, Ohio

Navigating Complexities: The Role of Custom Injection Molded Packaging in Heavy-Duty Container Logistics

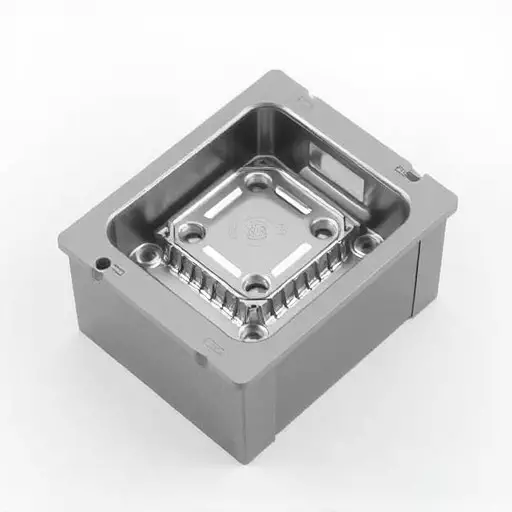

In the realm of heavy-duty container logistics, custom injection molded packaging from Holland, Ohio, plays a pivotal role in safeguarding and organizing contents during transportation. The intricate dance of logistics demands packaging solutions that are both robust and adaptable to various cargo sizes and shapes. Professional injection molding services in the region provide such solutions, crafting containers tailored to the specific needs of heavy-duty transport. These custom packages offer a host of benefits over standard options; they provide superior protection against impact and environmental factors, ensuring that contents arrive undamaged at their destination. The precision and durability of injection molded packaging also facilitate better stacking, space utilization, and weight distribution within the container, which is critical for maintaining structural integrity during transit. Moreover, the customizable nature of these containers allows for optimal configuration based on the cargo’s unique requirements, enhancing overall logistical efficiency and reducing the potential for costly damages or delays. The strategic location of Holland, Ohio, as a hub for transportation networks, further underscores the importance of its role in providing high-quality injection molding services to support the complex needs of heavy-duty container logistics. This synergy between advanced packaging solutions and centralized transportation infrastructure ensures that goods are packaged effectively, ready to withstand the rigors of long-haul travel across various terrains and climates.

Efficiency and Durability: Advantages of Injection Molded Containers in Supply Chain Operations

In the realm of heavy-duty container logistics, efficiency and durability stand out as paramount concerns for maintaining a robust supply chain. Custom injection molded packaging from Holland, Ohio, offers significant advantages that address these critical aspects. These containers are engineered with precision through professional injection molding services, resulting in products that consistently meet the rigorous demands of logistics operations. The benefits of injection molded packaging extend beyond mere containment; they encompass the ability to withstand harsh environmental conditions and repetitive handling without losing integrity. This resilience minimizes the risk of damage during transit, thereby reducing product loss and enhancing the overall efficiency of supply chain movements. Moreover, the customizable nature of these containers allows for optimal design solutions tailored to specific cargo requirements, ensuring that each container provides the perfect fit for its contents, further bolstering the protection offered. The durability and repeatable performance of injection molded packaging contribute to a more reliable and efficient supply chain, a testament to the advanced capabilities of the industry’s leading manufacturing services in Holland, Ohio.

Strategies to Overcome Obstacles in Container Logistics with Professional Injection Molding Services

In the realm of heavy-duty container logistics, the integration of custom injection molded packaging from companies like those in Holland, Ohio, presents a robust solution to numerous challenges faced by the industry. These bespoke packaging solutions are engineered to meet specific needs, ensuring that contents are protected against a myriad of environmental and operational risks during transit. The benefits of injection molded packaging are manifold; it offers superior durability, structural integrity, and can be tailored to fit complex shapes without adding unnecessary weight. This is particularly advantageous for heavy-duty container logistics where space and weight optimization are critical. Moreover, the precision and consistency of injection molding processes translate into reliable containers that can withstand the rigors of international shipping, reducing the likelihood of damage and associated delays.

To effectively tackle obstacles in container logistics, leveraging professional injection molding services is a strategic move. These services not only provide high-quality, custom packaging options but also support scalability and flexibility in operations. By adopting injection molded packaging solutions, companies can streamline their supply chains, improve turnaround times, and enhance the overall efficiency of logistics operations. The adaptability of these packages allows businesses to respond quickly to changing market demands or to accommodate fluctuating volumes without compromising on the protection of goods. This proactive approach not only mitigates potential risks but also positions companies to capitalize on new opportunities in an increasingly competitive global marketplace.

Case Study: Streamlining Logistics with Custom Solutions from Holland, Ohio

In the realm of heavy-duty container logistics, the challenges are as diverse as the products being transported. A prime example of overcoming these logistical hurdles is found in Holland, Ohio, where a leading provider of custom injection molded packaging has made significant strides. This company, recognized for its professional injection molding services, has tailored solutions that have revolutionized the way heavy-duty containers are handled and shipped. The benefits of opting for injection molded packaging are manifold: from enhancing product protection to ensuring efficient stacking and space utilization during transit. These custom solutions are designed with precision engineering to withstand the rigors of logistics, providing durability and reliability that are critical in maintaining the integrity of the contents. The result is a streamlined logistics process that minimizes damage, reduces waste, and ultimately lowers costs for clients. This case study exemplifies how innovative packaging solutions can address the complex needs of heavy-duty container logistics, making custom injection molded packaging from Holland, Ohio a strategic asset in the supply chain network. The company’s commitment to excellence and its deep understanding of the industry have set a new standard for others to follow, showcasing the tangible benefits that come with embracing advanced injection molding technologies.