The article discusses the importance of steel packaging solutions as a sustainable and efficient way to protect industrial equipment during distribution. These tailored containers are crafted for their durability, efficiency, and environmental friendliness, providing superior protection while reducing costs and environmental impact compared to bulkier alternatives. Steel’s high recyclability, aligning with eco-conscious consumer trends and regulatory standards, positions it as a top sustainable packaging choice. Its ability to be reused without compromising quality or strength supports closed-loop systems that conserve resources and reduce carbon emissions. The customizable nature of these steel packages ensures minimal waste, further enhancing their sustainability. The section concludes by highlighting the innovative approach of these solutions in advancing operational efficiency and environmental stewardship within the industrial sector. Steel packaging is presented as a key player in sustainable practices, offering robust protection for heavy-duty machinery without sacrificing performance or environmental responsibility. Manufacturers adopting these custom steel packaging options are embracing a greener production chain that supports circular economy principles by reducing waste and promoting material efficiency.

Steel packaging solutions are transforming the industrial landscape by offering robust, sustainable options that meet the unique needs of heavy-duty equipment. This article delves into the pivotal role these tailored containers play in maximizing efficiency and sustainability. We explore their environmental impact, highlighting the benefits they bring to manufacturing processes. Additionally, we examine design considerations that ensure industrial components are protected and preserved during transport and storage. Finally, we investigate innovative applications where steel packaging solutions significantly enhance safety and durability for heavy-duty equipment, underscoring their indispensable role in modern industry.

- Maximizing Efficiency and Sustainability with Custom Steel Packaging Solutions for Industrial Equipment

- Exploring the Environmental Impact and Benefits of Sustainable Steel Packaging in Manufacturing

- Design Considerations for Tailored Steel Packaging to Protect and Preserve Industrial Components

- Innovative Applications: The Role of Steel Packaging Solutions in Enhancing Safety and Durability for Heavy-Duty Equipment

Maximizing Efficiency and Sustainability with Custom Steel Packaging Solutions for Industrial Equipment

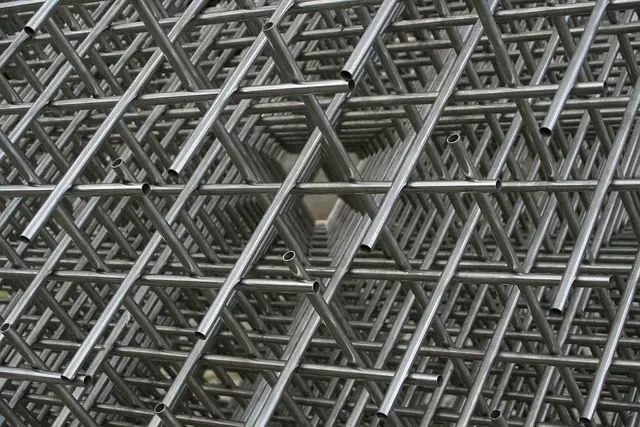

In the realm of industrial equipment, the adoption of robust and reliable packaging solutions is paramount to ensure the safety and integrity of the products throughout their distribution journey. Custom steel packaging solutions stand out as a pinnacle of efficiency and sustainability in this domain. These tailor-made containers are engineered to provide superior protection against environmental factors and potential damage during transport, thereby minimizing the risk of product spoilage or equipment failure post-shipment. The durability and resilience of steel contribute to a reduced need for additional packaging materials, which not only cuts down on costs but also lessens the environmental footprint typically associated with bulkier packaging options.

Sustainable steel packaging emerges as a strategic choice for companies aiming to align with eco-conscious consumer preferences and regulatory standards. The recyclability of steel makes it an ideal material for sustainable packaging solutions, as it can be repurposed time and again without loss of quality or strength. This closed-loop system not only conserves natural resources but also reduces the carbon footprint associated with traditional packaging materials. Moreover, customizing these steel packages to fit the exact dimensions and specifications of industrial equipment ensures that there is minimal waste, further enhancing the sustainability profile of the entire operation. With a focus on innovation and environmental stewardship, custom steel packaging solutions are setting a new benchmark for efficiency and sustainability in the industrial sector.

Exploring the Environmental Impact and Benefits of Sustainable Steel Packaging in Manufacturing

Steel packaging solutions have emerged as a pivotal component in the manufacturing industry, offering robust protection for industrial equipment while also presenting significant environmental considerations. Sustainable steel packaging, with its remarkable recyclability and minimal environmental footprint, stands out as an eco-friendly alternative to conventional packaging materials. The lifecycle of steel packaging is characterized by its high recovery rate; it can be recycled repeatedly without loss of quality, effectively reducing the demand for virgin materials and the associated environmental impact. Custom steel packaging solutions are tailored to meet specific requirements, ensuring optimal protection during transit and storage while aligning with sustainability goals. These custom options often feature designs that maximize material efficiency, further lessening the ecological imprint. By adopting such sustainable steel packaging, manufacturers can significantly contribute to waste reduction and resource conservation, thereby fostering a more environmentally responsible production process. The adoption of these steel solutions also aligns with broader industry trends towards circular economy principles, where the focus is on creating closed-loop systems that minimize waste and make the most efficient use of resources. In doing so, the manufacturing sector not only safeguards its products during transportation but also demonstrates a commitment to environmental stewardship.

Design Considerations for Tailored Steel Packaging to Protect and Preserve Industrial Components

When safeguarding industrial components, design considerations for tailored steel packaging solutions play a pivotal role in ensuring protection and preservation throughout the supply chain. These considerations are informed by the unique attributes of steel as a packaging material, including its inherent strength and durability. Selecting the appropriate gauge and alloy for the packaging ensures that the industrial components within are shielded from external pressures, such as impacts and environmental factors. Additionally, the design must account for the specific dimensions and weight distribution of the items being packaged, which can be achieved through custom steel packaging options. This bespoke approach not only offers optimal protection but also contributes to sustainability by minimizing material waste and promoting reusability. The integration of sustainable practices in the manufacturing process of these steel packaging solutions underscores the commitment to environmental stewardship, aligning with global initiatives towards greener logistics and packaging alternatives. Moreover, customization allows for the incorporation of features like cushioning pads, internal bracing, and anti-corrosive coatings, all of which enhance the packaging’s ability to withstand transit and storage challenges while maintaining the integrity of the industrial components it houses. These design innovations ensure that steel packaging solutions are not only robust and reliable but also environmentally conscious, providing a cost-effective and sustainable option for protecting industrial equipment during transport and storage.

Innovative Applications: The Role of Steel Packaging Solutions in Enhancing Safety and Durability for Heavy-Duty Equipment

In the realm of industrial equipment, the protection and preservation of heavy-duty machinery during transportation and storage are paramount. Steel packaging solutions have emerged as a robust contender in this domain, offering unparalleled safety and durability. These solutions are designed with a keen focus on the unique challenges faced by the sector, ensuring that each package is tailored to meet the specific needs of its contents. The use of sustainable steel packaging is particularly noteworthy, as it reduces environmental impact without compromising on protection or performance. Manufacturers are increasingly turning to these eco-friendly options, which are engineered to withstand harsh conditions and provide long-lasting security against damage during transit. Custom steel packaging solutions further enhance this protective capability by offering bespoke designs that fit the precise dimensions of the equipment they house. This not only minimizes the risk of movement within the package but also ensures optimal stability, eliminating the potential for damage due to impact or environmental factors. The integration of advanced technologies in these packages, such as corrosion-resistant coatings and tamper-evident seals, further augments their protective prowess, making them an indispensable tool for safeguarding heavy-duty equipment throughout its lifecycle.

In conclusion, the strategic implementation of custom steel packaging solutions stands as a pivotal advancement in safeguarding and sustaining industrial equipment across various sectors. The discourse on efficiency, sustainability, and environmental impact reveals that sustainable steel packaging emerges not merely as a protective measure but as a cornerstone for eco-conscious manufacturing practices. By meticulously designing these solutions to meet the unique demands of heavy-duty components, the industry is poised to enhance both the safety and longevity of its equipment, ultimately driving innovation and operational efficiency. As industries continue to evolve and prioritize environmental stewardship, steel packaging solutions are set to play an integral role in this transformative journey.