Kitchen suppression inspections in Spring Lake are crucial for commercial kitchen fire safety. Regular checks by professionals ensure equipment functionality, proper placement of nozzles, and adequate water supply, identifying potential risks. Adhering to local regulations through these inspections prevents costly failures, protects facilities, and ensures compliance with fire suppression standards. Optimizing systems with tailored maintenance, routine tests, and debris removal enhances kitchen safety and minimizes regulatory penalties.

In the bustling kitchen environments of Spring Lake, efficient fire suppression systems are non-negotiable. This article delves into the crucial aspect of kitchen suppression system performance analysis, offering a comprehensive guide for operators and safety professionals. We explore the significance of understanding these systems, emphasizing regular inspections and compliance checks to ensure optimal safety measures. Learn effective strategies to optimize your Spring Lake kitchen’s fire suppression system and maintain vital fire safety standards.

- Understanding Kitchen Suppression Systems: A Comprehensive Overview

- The Importance of Regular Inspection and Compliance Checks

- Effective Strategies for Optimizing Suppression System Performance in Spring Lake Kitchens

Understanding Kitchen Suppression Systems: A Comprehensive Overview

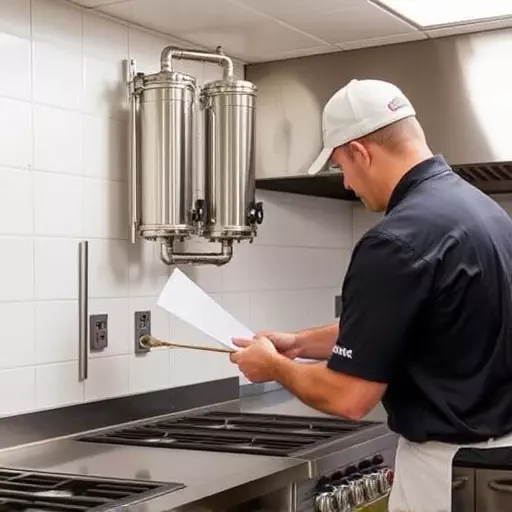

Suppression systems in commercial kitchens are critical lifelines for fire safety and survival. These sophisticated networks of pipes, nozzles, and extinguishers are designed to combat fires swiftly and effectively, minimizing damage and saving lives. A Kitchen Suppression Inspection Spring Lake service plays a vital role in ensuring these systems remain operational and up-to-code, facilitating fire suppression compliance checks that can detect any issues or deficiencies.

Regular kitchen suppression system inspections are essential for several reasons. They allow professionals to assess the condition of fire suppression equipment, verify proper placement and functionality of nozzles, and ensure adequate water supply. Moreover, these inspections identify potential risks and bottlenecks in the system’s design, enabling timely repairs or upgrades. By adhering to fire suppression compliance standards, commercial kitchens can protect their facilities, employees, and patrons from the devastating consequences of fires.

The Importance of Regular Inspection and Compliance Checks

Regular kitchen suppression inspection and fire suppression compliance checks are paramount for any commercial kitchen or facility in Spring Lake. These routine assessments ensure that critical safety systems, designed to mitigate the risks of fires, are functioning optimally. A well-maintained kitchen suppression system can mean the difference between a minor inconvenience and a major disaster.

By conducting thorough inspections, professionals can identify potential issues, such as faulty equipment, blockages, or outdated systems. Compliance checks ensure adherence to local fire safety regulations, which often require regular maintenance and testing. This proactive approach not only enhances the overall safety of the kitchen but also helps to prevent costly repairs or replacements in case of a system failure during an actual emergency.

Effective Strategies for Optimizing Suppression System Performance in Spring Lake Kitchens

In Spring Lake kitchens, optimizing fire suppression system performance is paramount for safety and regulatory compliance. Regular kitchen suppression inspections are a critical first step. These thorough checks should assess every component—from sprinkler heads to control valves—for any signs of damage, corrosion, or malfunction. By identifying and addressing issues early, property owners can prevent costly repairs during emergency situations and ensure fire suppression systems operate effectively when needed most.

Effective strategies for maximizing kitchen suppression system performance include implementing a maintenance schedule tailored to the specific needs of Spring Lake commercial kitchens. This proactive approach involves routine tests, pressure checks, and cleaning to remove any buildup or debris that could hinder system efficiency. Additionally, staying up-to-date with fire suppression compliance checks ensures adherence to local codes, minimizing penalties and enhancing overall kitchen safety.