Maintaining optimal performance and safety in Holland, Ohio's loading and unloading equipment is critical for warehousing success. Adhering to proven warehouse loading techniques and stringent unloading safety protocols minimizes downtime, enhances productivity, and ensures worker safety. Regular equipment inspections, strategic pallet arrangement, and employee training are key to efficient, secure, and cost-effective operations. Specializing in these best practices, loading and unloading services Holland Ohio can revolutionize logistics workflows, reduce costs, and meet delivery timelines with enhanced reliability.

In the dynamic landscape of logistics, efficient loading and unloading processes are pivotal for any warehouse operation. For businesses in Holland, Ohio, seeking optimal performance and safety, regular maintenance of loading equipment is non-negotiable. This comprehensive guide delves into essential practices, from understanding maintenance’s significance to implementing effective schedules. We explore warehouse loading techniques, unloading safety protocols, common issue prevention, training best practices, and real-world case studies, offering a robust framework for enhancing your loading and unloading services in Holland, Ohio.

- Understanding the Importance of Regular Maintenance for Loading Equipment

- Essential Warehouse Loading Techniques to Optimize Efficiency

- Unloading Safety Protocols: Protecting Your Team and Goods

- Common Issues in Loading and Unloading Processes and How to Prevent Them

- The Role of Training in Ensuring Safe Loading and Unloading Practices

- Implementing Effective Maintenance Schedules for Different Equipment Types

- Case Studies: Success Stories in Loading and Unloading Service Maintenance

Understanding the Importance of Regular Maintenance for Loading Equipment

Regular maintenance is paramount for ensuring the efficient operation of loading and unloading equipment in Holland, Ohio. These machines play a crucial role in warehouse loading techniques, facilitating the swift movement of goods. Without proper care, however, they can become a safety hazard and lead to costly downtime. Unloading safety protocols demand regular checks to identify and rectify potential issues before they escalate.

Maintaining these systems involves routine inspections, lubrication, and part replacements. Following established unloading safety protocols not only extends the lifespan of the equipment but also boosts the overall safety of the warehouse environment. For businesses relying on efficient loading and unloading services Holland Ohio offers, prioritizing maintenance is a strategic decision that translates to smoother operations and reduced risks.

Essential Warehouse Loading Techniques to Optimize Efficiency

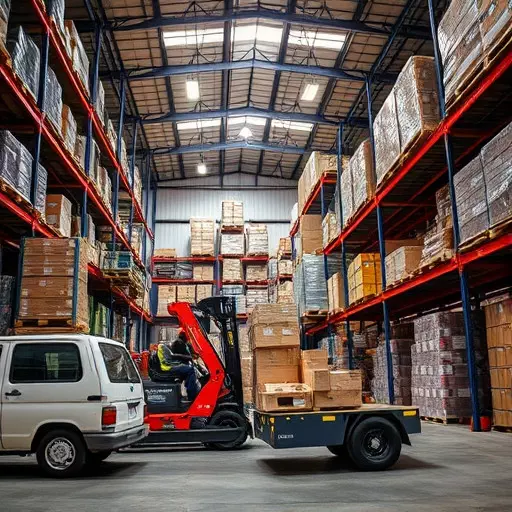

In the dynamic landscape of logistics, efficient warehouse loading and unloading are paramount to success. Implementing proven warehouse loading techniques can significantly optimize operations, enhance productivity, and streamline your supply chain in Holland, Ohio. A well-organized approach starts with prioritizing safety protocols during unloading. This involves securing loose items, using appropriate lifting equipment, and ensuring clear pathways to prevent accidents and injuries.

Moreover, maximizing space utilization within the warehouse is key. Strategically arranging pallets and goods on storage racks or floors can facilitate faster loading and unloading processes. Employing specialized loading and unloading services in Holland, Ohio, that understand these best practices can revolutionize your operations. From optimizing load sizes to implementing efficient stacking methods, these professionals ensure your inventory moves smoothly through the warehouse, reducing time and labor costs.

Unloading Safety Protocols: Protecting Your Team and Goods

When it comes to loading and unloading equipment, safety should always be the top priority. Proper unloading safety protocols are essential to protect both your team and the goods they’re handling. In Holland, Ohio, where warehousing and logistics operations are common, implementing robust safety measures can significantly reduce risks associated with these processes.

Start by ensuring clear communication among all team members. Define specific roles and responsibilities during loading and unloading to avoid confusion. Use proper personal protective equipment (PPE), such as reflective vests, hard hats, and safety glasses, especially when handling heavy items or working in low-light conditions. Regularly inspect the equipment for any signs of damage or wear, and maintain a well-organized warehouse layout to facilitate smooth material flow, minimizing the risk of tripping hazards and collisions.

Common Issues in Loading and Unloading Processes and How to Prevent Them

In the efficient world of logistics, loading and unloading are critical processes that can make or break a successful operation. Common issues in these areas include equipment malfunctions, improper handling of materials, and safety hazards. To mitigate these problems, it’s essential to implement effective warehouse loading techniques and adhere to strict unloading safety protocols.

For loading and unloading services Holland Ohio, businesses should prioritize regular maintenance checks on all equipment. This proactive approach ensures that machinery is in optimal condition, reducing the risk of unexpected breakdowns during busy periods. Additionally, providing comprehensive training for staff on proper handling practices can significantly decrease accidents and damage to goods. By focusing on these areas, operations can streamline their processes, enhance efficiency, and maintain a safe working environment.

The Role of Training in Ensuring Safe Loading and Unloading Practices

Training plays a pivotal role in upholding safety standards during loading and unloading processes at warehouses or distribution centers. Equipping employees with comprehensive knowledge and skills ensures efficient and secure handling of goods, minimizing the risk of accidents and injuries. This is particularly crucial for high-volume operations where rapid loading and unloading are essential to meet delivery deadlines.

In the context of loading and unloading services Holland Ohio, businesses should invest in regular training sessions that cover various warehouse loading techniques and unloading safety protocols. These programs should educate staff on proper equipment operation, load securement, and emergency response procedures. By fostering a culture of safety through continuous learning, organizations can create a seamless, accident-free environment for both employees and cargo during the critical loading and unloading phases.

Implementing Effective Maintenance Schedules for Different Equipment Types

Implementing effective maintenance schedules is crucial for ensuring optimal performance in various equipment types used in loading and unloading processes at warehouses. In Holland, Ohio, where efficient logistics operations are paramount, adopting tailored maintenance routines can significantly enhance productivity while minimizing downtime. For instance, specialized equipment like forklifts, conveyor systems, and material handling machinery require distinct care routines based on their specific functions and usage patterns. A well-structured maintenance schedule should incorporate regular inspections, lubrication, and part replacements to prevent unexpected breakdowns during critical loading and unloading services.

When it comes to warehouse loading techniques, proper training on equipment operation and safety protocols for unloading is essential. Adhering to standardized procedures not only improves efficiency but also guarantees the safety of workers and merchandise. By integrating these practices into daily operations, facilities in Holland, Ohio, can maintain a seamless flow of goods, ensuring client satisfaction and operational smoothness despite varying equipment types and usage intensities.

Case Studies: Success Stories in Loading and Unloading Service Maintenance

In the dynamic landscape of logistics, successful loading and unloading operations are a testament to meticulous planning and consistent maintenance. Case studies from leading warehousing companies in Holland, Ohio, highlight the impact of implementing robust loading and unloading service maintenance routines. These best practices include adopting advanced warehouse loading techniques, such as optimized conveyor systems and automated pallet stacking, which enhance efficiency while minimizing worker strain.

Furthermore, these forward-thinking firms prioritize unloading safety protocols, ensuring that all personnel are thoroughly trained in handling hazardous materials and operating heavy machinery. By fostering a culture of safety and implementing data-driven maintenance schedules, they’ve achieved remarkable reductions in downtime, increased equipment lifespan, and improved overall operational reliability. These success stories serve as a beacon for other businesses, demonstrating the transformative power of prioritizing equipment maintenance within the bustling logistics industry.