The city of Toledo, Ohio, has embraced pavement milling and grinding as a key method for maintaining its road infrastructure, focusing on precise removal and repair of damaged asphalt or concrete. This approach not only addresses issues like potholes effectively but also aligns with sustainable practices by recycling removed material and minimizing environmental impact. Toledo's public works departments utilize advanced technologies to assess pavement conditions accurately, ensuring a stable foundation for new materials. The city's commitment to efficiency and safety is evident in its use of modern equipment, precise cutting technology, and careful planning to conduct repairs during less congested periods, thus reducing traffic disruptions. The integration of these techniques in Toledo exemplifies the city's dedication to long-term sustainability goals and enhances the quality and durability of its roads, contributing to a better driving experience for residents and visitors. Keywords 'pavement milling and grinding' and 'pavement milling and grinding Toledo Ohio' highlight Toledo's innovative and proactive approach in infrastructure maintenance.

Potholes are more than mere inconveniences; they are indicators of a city’s infrastructure health and can significantly impact vehicle longevity and road user safety. In Toledo, Ohio, the approach to addressing these imperfections involves advanced pavement milling and grinding techniques. This article delves into the intricacies of this process, highlighting its role in maintaining the city’s roadways, assessing damage, ensuring safety, and exploring the environmental implications. From the initial steps of identifying suitable potholes to the detailed procedures of milling and grinding, readers will gain insights into how Toledo tackles pavement repairs sustainably and effectively, as evidenced by a compelling case study that underscores the city’s commitment to infrastructure excellence.

- Overview of Pavement Milling and Grinding for Pothole Repair

- The Role of Milling Machines in Toledo, Ohio's Infrastructure Maintenance

- Assessing Pavement Damage: Identifying Suitable Potholes for Milling Operations

- Preparing the Work Zone: Safety and Efficiency Considerations

- Step-by-Step Process of Pavement Milling and Grinding

- The Environmental Impact and Sustainability of Pavement Milling in Toledo, Ohio

- Case Study: Successful Pothole Repair through Milling in Toledo, Ohio's Roadways

Overview of Pavement Milling and Grinding for Pothole Repair

Pavement milling and grinding are essential processes in the maintenance and repair of roadways, particularly when addressing potholes. These techniques involve the precise removal of damaged asphalt or concrete from a road’s surface to prepare it for repairs or repaving. The process begins with the identification of defective areas, such as potholes, which are then carefully milled to match the existing pavement profile. This ensures a seamless integration of the new material and maintains the structural integrity of the road.

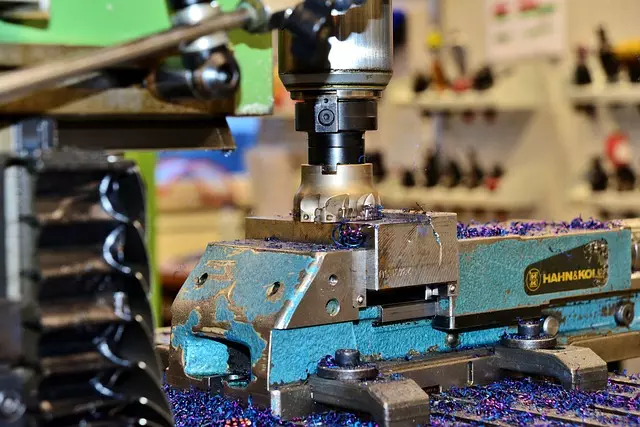

In Toledo, Ohio, as in many cities, pavement milling and grinding play a critical role in the upkeep of infrastructure. The city’s Department of Transportation employs state-of-the-art milling machines to efficiently remove the compromised portions of the road. These machines can be adjusted to mill away the exact depth required for effective pothole repair, which is crucial for both short-term fixes and long-term durability. The precision of these operations minimizes disruptions to traffic flow and extends the lifespan of the pavement, thereby enhancing road safety and user experience. The expertise in pavement milling and grinding tolededo ohio showcases the city’s commitment to maintaining its road network effectively.

The Role of Milling Machines in Toledo, Ohio's Infrastructure Maintenance

In Toledo, Ohio, the maintenance and repair of urban infrastructure are critical tasks that ensure the safety and efficiency of roadways. Pavement milling and grinding play a pivotal role in this process, serving as an essential method for the precise removal of damaged asphalt or concrete to prepare for repairs and repaving. This technique is not only cost-effective but also minimizes traffic disruptions by allowing for quick reconstruction of road surfaces. In Toledo, local public works departments leverage pavement milling and grinding technology to precisely cut out potholes, patchwork, and other surface irregularities, facilitating the seamless integration of new materials into the existing infrastructure. This approach not only extends the lifespan of roads but also enhances their structural integrity, contributing significantly to the overall quality of Toledo’s road network.

The use of advanced milling machines in Toledo is a testament to the city’s commitment to sustainable and efficient infrastructure maintenance. These machines are capable of performing precise cuts, ensuring that only the damaged portions of pavement are removed. The resulting material can be recycled, reducing waste and environmental impact. The precision of pavement milling and grinding in Toledo also minimizes the amount of asphalt or concrete used, which aligns with eco-friendly construction practices. By utilizing this technology, Toledo’s infrastructure maintenance efforts are not only effective in addressing current issues but also support long-term sustainability goals. The city’s investment in pavement milling and grinding equipment underscores the importance of leveraging modern technology to maintain and improve its urban infrastructure.

Assessing Pavement Damage: Identifying Suitable Potholes for Milling Operations

Pavement milling and grinding is a critical process in the maintenance and repair of road infrastructure, particularly for addressing pothole issues. This method involves removing the damaged asphalt or concrete to prepare the area for repairs or resurfacing. Assessing pavement damage accurately is the first step in determining which potholes are suitable for milling operations. Technicians utilize a combination of visual inspection and advanced technologies, such as infrared scanning and ground-penetrating radar, to identify and evaluate the extent of the surface degradation. These assessments help determine the necessary depth of milling required to remove the compromised material and ensure a stable base for new asphalt placement.

In Toledo, Ohio, the Department of Public Utilities, along with private contractors, employs pavement milling and grinding as part of their regular maintenance routine. The city’s infrastructure demands a meticulous approach to repair potholes and other forms of pavement damage. The process begins with a detailed evaluation of the pothole’s size, depth, and location, which influences the type of milling equipment and technique used. For instance, larger or deeper potholes may require more sophisticated machinery capable of adjusting to various milling depths for an effective repair. The milled material is then repurposed when possible, showcasing a commitment to sustainability within the city’s operations. The end result is a smoother, safer driving experience for Toledo’s residents and visitors alike.

Preparing the Work Zone: Safety and Efficiency Considerations

When addressing pothole repairs through pavement milling and grinding, safety and efficiency are paramount in preparing the work zone. This process involves precision machinery that cuts and removes damaged asphalt to prepare for repair or resurfacing. In Toledo, Ohio, as elsewhere, crews must establish a secure and well-organized work environment to ensure both the workers’ and motorists’ safety. Barricades, signage, and cones are strategically placed to delineate the work area and guide traffic around the operations. The use of advanced pavement milling equipment in Toledo, Ohio, requires skilled operators adhering to strict safety protocols. These measures not only protect workers from oncoming traffic and machinery-related hazards but also minimize disruptions to traffic flow. Efficiency is enhanced by pre-planning the work zone layout, selecting optimal machinery for the task, and coordinating with local authorities to time the repairs during off-peak hours when possible. This approach ensures that the pavement milling and grinding process in Toledo, Ohio, is carried out swiftly, reducing the inconvenience to drivers and expediting the return of the road to full functionality. The integration of technology, such as GPS-guided systems for precision cutting, further streamlines operations, allowing for more consistent and high-quality repairs that extend the longevity of the pavement.

Step-by-Step Process of Pavement Milling and Grinding

Pavement milling and grinding is a critical step in the maintenance and repair of roadways, serving as a foundation for effective pothole repairs and overall infrastructure health. The process begins with an assessment of the damaged area, where precise measurements are taken to determine the extent of the repair needed. Once evaluated, the milling machine is deployed to remove the defective material. These machines, equipped with rotating drums or discs, precisely cut into the pavement at a controlled depth, ensuring that only the compromised layer is removed without undermining the structural integrity of the road.

In Toledo, Ohio, as in many other locations, the Department of Transportation (DOT) employs advanced milling and grinding techniques to address pothole issues and maintain road quality. The process involves selecting the appropriate milling machine for the job, considering factors such as the type of pavement, depth of the damaged area, and the desired final surface profile. The milling operation is conducted with careful attention to detail, ensuring that the edges of the removed material are clean and straight to facilitate seamless patchwork and minimize future repair needs. After the affected section is milled away, the resulting cavity is carefully inspected before being filled with fresh asphalt. This meticulous approach to pavement milling and grinding in Toledo, Ohio, ensures a smooth and durable repair that contributes to the longevity and safety of the road network.

The Environmental Impact and Sustainability of Pavement Milling in Toledo, Ohio

Pavement milling and grinding play a crucial role in the maintenance and sustainability of Toledo, Ohio’s infrastructure. This process involves removing the top layer of asphalt or concrete from roads to repair issues such as potholes or to prepare for repaving. In the context of environmental impact, pavement milling offers several benefits. The recycling aspect of this process significantly reduces the need for new materials, thus conserving natural resources and minimizing landfill usage. The milled material can be reused in the construction of new roadways or as base material for other projects, closing the loop on a circular resource model. This not only lessens the environmental footprint but also aligns with Toledo’s sustainability goals.

Furthermore, the method is designed to minimize disruptions and can be performed with precision, ensuring that only the damaged sections of pavement are removed. Advanced equipment used in pavement milling and grinding in Toledo can control dust and emissions, further reducing its environmental impact. The local government’s commitment to using this eco-friendly method demonstrates a proactive approach to infrastructure management and sustainability. The implementation of pavement milling and grinding as a standard practice for pothole repair in Toledo showcases the city’s dedication to maintaining its streets while upholding environmental standards, contributing positively to the overall health and vitality of the urban landscape.

Case Study: Successful Pothole Repair through Milling in Toledo, Ohio's Roadways

In Toledo, Ohio, the Department of Public Infrastructure has effectively utilized pavement milling and grinding techniques to address the issue of potholes on its roadways. This innovative approach has proven to be a reliable method for pothole repair, ensuring a smoother and safer driving experience for residents and commuters alike. When a pothole is detected, the process begins with the precise removal of the damaged asphalt using specialized milling machinery. This machinery operates by grinding away the defective surface layer to the specified depth, allowing for a clean and accurate repair. The milled material is then carefully removed from the site, leaving a prepared area ready for patching or overlay work. The effectiveness of this method in Toledo is evident in the durability and quality of the repaired road surfaces. Not only does pavement milling and grinding facilitate a more permanent solution to pothole issues, but it also minimizes traffic disruptions and allows for faster return to normal traffic flow compared to traditional repair methods. This case study from Toledo underscores the benefits of employing advanced pavement milling and grinding techniques for effective road maintenance and repair. The city’s commitment to this method has resulted in improved public infrastructure, contributing to the overall safety and efficiency of its transportation network.