Pavement milling and grinding plays a crucial role in maintaining Toledo, Ohio's roadways, with recent advancements significantly enhancing its precision and efficiency. This process involves carefully removing compromised asphalt to facilitate effective pothole repair and resurfacing. Toledo employs state-of-the-art machinery equipped with GPS guidance systems to target damaged areas precisely, preserving the structural integrity of the pavement while minimizing waste. The incorporation of real-time data analytics tailors operations to local asphalt and weather conditions, ensuring high-quality repairs. Robotics and automation contribute to safer work environments by reducing dust and accident risks. Toledo's approach exemplifies a forward-thinking public works project, aiming for a smoother and safer driving experience through sustainable practices that recycle milled materials. This method not only addresses immediate road concerns but also preemptively maintains the structural integrity of the city's roads, serving as an effective model for other municipalities. The integration of advanced technology in Toledo's pavement milling and grinding operations underscores its importance in long-term infrastructure maintenance and safety.

When confronted with the challenge of urban infrastructure maintenance, pothole repair stands out as a critical task. This article delves into the intricacies of pavement milling and grinding, a process integral to effective pothole remediation. We explore its methodology, technological advancements enhancing the process, and a case study highlighting its application in Toledo, Ohio. By examining best practices for implementing this technique, readers will gain insight into how pavement milling and grinding contributes to sustaining robust road networks.

- Understanding Pavement Milling and Grinding: The Process Behind Efficient Pothole Repairs

- The Role of Technology in Pavement Milling and Grinding Operations

- Case Study: Pavement Milling and Grinding to Toledo Ohio's Infrastructure Maintenance

- Best Practices for Implementing Pavement Milling and Grinding in Pothole Repair Projects

Understanding Pavement Milling and Grinding: The Process Behind Efficient Pothole Repairs

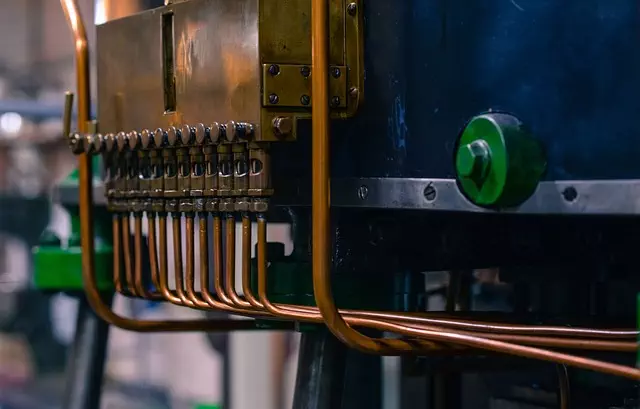

Pavement milling and grinding are critical processes in the maintenance and repair of roadways, particularly when addressing potholes. These techniques involve the removal of the damaged surface layer of asphalt to prepare for repairs or resurfacing. The process begins with setting up traffic controls and safety measures to ensure the safety of both workers and motorists. A milling machine, which consists of a rotating drum equipped with teeth, is then used to grind away the defective pavement material. In Toledo, Ohio, as in many places, this specialized equipment is deployed to address the unique challenges of local road conditions, such as those encountered on highways, city streets, and parking lots. The depth of milling is precise, removing only the damaged section while preserving the underlying layers that remain intact and structurally sound. Once the pothole or damaged area is properly milled, the resulting material can be repurposed or removed, and a new layer of asphalt can be applied to restore the road’s integrity and smoothness. This not only enhances the driving experience but also extends the lifespan of the pavement, making it a cost-effective and sustainable solution for pothole repairs in Toledo, Ohio.

The Role of Technology in Pavement Milling and Grinding Operations

In recent years, advancements in technology have significantly enhanced the efficiency and precision of pavement milling and grinding operations, which are critical components of infrastructure maintenance. These high-tech machines, utilized extensively in Toledo, Ohio, for instance, employ GPS guidance systems to ensure milled material is removed with unprecedented accuracy, minimizing waste and ensuring a more precise base for the repair work. The integration of real-time data analytics allows contractors to optimize the process, adjusting parameters on the fly to match the specific asphalt composition and weather conditions, thereby improving the quality of the repaired surface. This technology not only streamlines operations but also extends the lifespan of pavements by ensuring that only the damaged material is removed, thus preserving the integrity of the overall structure.

Furthermore, the integration of robotics and automation in pavement milling and grinding has led to safer work environments. These robotic systems can operate with minimal human intervention, reducing exposure to harmful dust and the risk of accidents. The use of such technology in Toledo, Ohio is a testament to the city’s commitment to embracing innovative solutions for public works projects. The precision and consistency provided by these advanced tools ensure that the repaired pavement not only meets but often exceeds quality standards, providing a smoother, safer driving experience for the community. The role of technology in pavement milling and grinding operations underscores the importance of staying abreast of technological advancements to maintain and repair infrastructure effectively.

Case Study: Pavement Milling and Grinding to Toledo Ohio's Infrastructure Maintenance

In Toledo, Ohio, the Department of Public Utilities has effectively utilized pavement milling and grinding as a cornerstone in maintaining its urban infrastructure. This process involves the precise removal of damaged or worn-out asphalt from road surfaces to prepare for repairs or resurfacing. The application of pavement milling and grinding in Toledo not only facilitates efficient and targeted maintenance but also extends the lifespan of the city’s roads. This method allows for a smooth transition between old and new layers of asphalt, ensuring a uniform and durable road surface that withstands the test of time and heavy traffic. The milled materials are often recycled, demonstrating Toledo’s commitment to sustainable infrastructure practices and reducing environmental impact.

The city has seen significant improvements in its transportation network as a result of integrating advanced pavement milling and grinding techniques into its maintenance schedule. This approach not only addresses immediate issues such as potholes but also preemptively ensures the structural integrity of the roadways. By leveraging this technology, Toledo’s infrastructure maintenance is both proactive and cost-effective, minimizing future repair costs and enhancing overall road safety for its residents. The case study of Toledo exemplifies how pavement milling and grinding can be a pivotal component in municipalities effectively managing their infrastructure needs.

Best Practices for Implementing Pavement Milling and Grinding in Pothole Repair Projects

Infrastructure maintenance is a critical aspect of ensuring road safety and longevity, with pothole repair being a fundamental component of this upkeep. Pavement milling and grinding play an integral role in effective pothole repairs. This process involves removing the damaged asphalt with specialized machinery to prepare for patching and resurfacing. In Toledo, Ohio, as in many places, mastery of pavement milling and grinding techniques is essential for creating a seamless and durable repair. Best practices for implementing these techniques begin with precise planning and execution. Firstly, it is crucial to assess the extent of the damage and determine the appropriate depth of the milling operation. This ensures that the affected area is fully removed without unnecessarily disturbing surrounding undamaged pavement. The removal process should be carried out with state-of-the-art equipment, operated by trained professionals. In Toledo, Ohio, for instance, such operations are often conducted by local contractors who are well-versed in the nuances of milling and grinding asphalt. After the damaged material is removed, the resulting cavity should be properly cleaned and prepared for the application of new asphalt. Additionally, dust collection systems must be utilized to minimize environmental impact and ensure air quality compliance. Finally, the patched area should be carefully blended with the surrounding pavement through precise milling techniques to create a smooth transition that prevents water intrusion and future pothole formation. By adhering to these best practices, pavement milling and grinding in Toledo, Ohio, can significantly enhance the quality and longevity of pothole repairs, contributing to safer travel conditions for all users of the roadway.