EPP molded foam packaging from Holland, Ohio suppliers offers a sustainable and efficient solution for businesses looking to protect products during transportation. These customizable packages are exceptionally lightweight yet robust, providing superior shock absorption and impact resistance. They help reduce shipping costs, minimize carbon emissions, and offer adaptable designs suitable for various industries including automotive, electronics, and healthcare. The Holland, Ohio-based suppliers excel in creating EPP foam packaging that fits precisely to the products it protects, ensuring maximum protection with minimal weight. This not only enhances product safety but also contributes to more sustainable logistics practices. Companies adopting these solutions report lower transportation costs, reduced damage rates, and improved customer satisfaction. The strategic location of Holland's EPP molded foam packaging suppliers ensures timely delivery and aligns with the region's commitment to innovation and environmental responsibility in the realm of lightweight epp packaging solutions.

Explore the resilient and adaptable world of stackable EPP molded foam packaging, a pivotal innovation in protective packaging. This article delves into the transformative role of EPP molded foam as a lightweight alternative for robust packaging solutions, emphasizing its significance for industries seeking durability without compromising on logistics efficiency. Discover how partnering with an experienced EPP molded foam packaging supplier in Holland, Ohio can revolutionize your packaging strategy, and learn about the customizable options that cater to diverse applications. From detailed design and manufacturing processes to real-world case studies, this comprehensive guide will illuminate the advantages of adopting EPP foam packaging for your business needs.

- Maximizing Protection with Custom EPP Molded Foam Packaging

- EPP Molded Foam: The Lightweight Alternative for Robust Packaging Solutions

- Choosing the Right EPP Molded Foam Supplier in Holland, Ohio

- The Advantages of Customizable EPP Foam Packaging for Various Industries

- EPP Molded Foam: Design and Manufacturing Processes Explained

- Case Studies: Successful Implementations of EPP Foam Packaging Solutions

- Innovative Lightweight EPP Packaging Strategies for Efficient Logistics

Maximizing Protection with Custom EPP Molded Foam Packaging

In the realm of protective packaging, EPP molded foam packaging has emerged as a game-changer for businesses seeking to safeguard their products during transit and handling. As a leading epp molded foam packaging supplier based in Holland, Ohio, businesses can leverage custom EPP foam solutions tailored to their unique needs. The lightweight nature of expanded polypropylene (EPP) offers unparalleled versatility, allowing for the creation of complex geometries that fit snugly around products, providing superior shock absorption and impact resistance. This not only ensures maximum protection against drops, vibrations, and environmental hazards but also reduces the overall weight of packaging systems, which is a critical advantage in reducing shipping costs and carbon footprint.

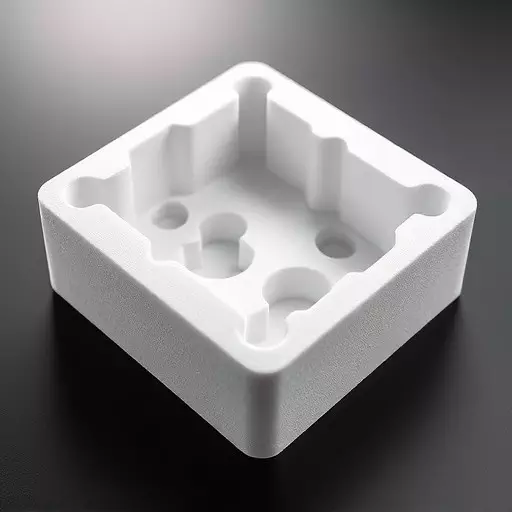

Custom EPP foam packaging solutions are meticulously designed to conform to the exact dimensions and contours of the products they protect. This bespoke approach minimizes material usage without compromising on protection, making it an eco-friendly option for companies aiming to implement sustainable practices. The adaptability of EPP molded foam means that it can be engineered to stack efficiently, providing a multi-layered protective barrier for products in storage or transit. Its robust yet flexible composition ensures that fragile items are well-cushioned, with the added benefit of being reusable and recyclable. By partnering with an EPP molded foam packaging supplier like the one in Holland, Ohio, businesses can enhance their supply chain operations, ensuring products arrive intact while demonstrating a commitment to environmental stewardship.

EPP Molded Foam: The Lightweight Alternative for Robust Packaging Solutions

EPP molded foam has emerged as a premier choice for robust packaging solutions across various industries. Offering unparalleled protection against impacts, vibrations, and environmental factors, this lightweight alternative to traditional packaging materials is revolutionizing the way companies pack, transport, and protect their products. Suppliers like those in Holland, Ohio, provide top-tier EPP molded foam packaging solutions tailored to meet diverse needs. The inherent properties of expanded polypropylene make it an ideal candidate for custom epp foam packaging designs. Its light weight significantly reduces shipping costs while maintaining durability and structural integrity. This means that products encased in EPP molded foam benefit from a high level of protection during transit, without the burden of excess weight. Moreover, the versatility of EPP allows for intricate designs and precise dimensions, ensuring that each package can be optimized for both efficiency and effectiveness. The environmental impact is also a consideration; EPP molded foam is fully recyclable and can be repurposed, making it an eco-friendly choice for businesses seeking sustainable packaging options.

Choosing the Right EPP Molded Foam Supplier in Holland, Ohio

When sourcing custom EPP molded foam packaging solutions in Holland, Ohio, it’s crucial to partner with a supplier that offers high-quality, reliable products tailored to your specific needs. The right supplier should have extensive experience and a comprehensive portfolio of lightweight EPP packaging options, ensuring your products are adequately protected during transit without adding unnecessary weight. In Holland, Ohio, businesses can benefit from suppliers who prioritize sustainability and innovation in their manufacturing processes, providing eco-friendly alternatives to traditional packaging materials. These suppliers not only contribute to reducing the environmental impact but also offer cost-effective solutions that maintain the integrity of your products.

Selecting a top-tier EPP molded foam packaging supplier in the Holland, Ohio area involves a thorough vetting process. It’s imperative to evaluate the supplier’s track record, the quality of their materials, and their commitment to customer service. A reputable supplier will offer quick turnaround times without compromising on the quality of the custom foam solutions they provide. They should also possess state-of-the-art molding equipment capable of producing intricate designs with precision and consistency. By choosing a reliable EPP molded foam packaging supplier in Holland, Ohio, businesses can ensure their products are packaged effectively, leading to increased customer satisfaction and fewer return due to damage during shipping.

The Advantages of Customizable EPP Foam Packaging for Various Industries

Customizable EPP foam packaging offers a myriad of advantages that cater to the diverse needs of various industries. As an epp molded foam packaging supplier, Holland, OH-based operations are well-positioned to deliver solutions tailored to specific client requirements. The lightweight nature of expanded polypropylene (EPP) foam packaging significantly reduces shipping weights and associated transportation costs, making it an environmentally friendly option while maintaining durability for the protection of sensitive goods during transit.

The adaptability of EPP foam allows for precise design modifications to accommodate products of various shapes and sizes without compromising on strength or integrity. This customizability ensures that each packaging solution is optimized for the specific needs of its intended contents, be it electronics, automotive components, or medical devices. The use of EPP foam as a material also contributes to sustainability efforts, as it is both recyclable and offers superior protection against impacts and vibrations. This not only protects the products but also aligns with corporate social responsibility objectives for businesses aiming to minimize their environmental footprint. Custom epp foam packaging, therefore, stands out as a smart investment for industries looking for efficient, versatile, and sustainable packaging solutions.

EPP Molded Foam: Design and Manufacturing Processes Explained

Engineered Polymer Process (EPP) molded foam offers a versatile and robust solution for packaging needs, particularly in industries demanding both protection and efficiency. The design process for EPP molded foam begins with a detailed understanding of the product it will encasement. Designers utilize sophisticated software to create precise molds that capture the intricacies of the item, ensuring a snug and protective fit. This customization allows for optimal cushioning against impacts, vibrations, and environmental hazards during transit.

Once the design is finalized, the manufacturing process commences. EPP molded foam is produced through a low-pressure chemical reaction known as gas generation. This reaction involves a stable prepolymer that, upon being activated by heat, releases carbon dioxide (CO2) to expand and take the shape of the mold. The result is a lightweight yet durable foam with consistent cell structure and superior energy absorption capabilities. EPP molded foam packaging suppliers like those in Holland, Ohio, excel at leveraging this process to deliver tailor-made solutions that meet specific customer requirements. Their expertise ensures that each piece of custom EPP foam packaging is crafted to provide the utmost protection for delicate products, making it an ideal choice for a variety of industries including automotive, electronics, and healthcare. The lightweight nature of these solutions also contributes to reduced shipping costs and environmental impact, further underscoring their value in modern supply chains.

Case Studies: Successful Implementations of EPP Foam Packaging Solutions

In recent years, stackable EPP foam packaging has emerged as a robust solution for businesses seeking to optimize their supply chain operations. A prime example of this is the success story of a leading EPP molded foam packaging supplier based in Holland, Ohio. This supplier has been instrumental in providing bespoke EPP foam packaging solutions that not only meet the specific needs of various industries but also adhere to sustainability practices. Their innovative approach to designing lightweight EPP packaging solutions has enabled clients to achieve significant reductions in transportation costs and carbon footprint. The durability and protective capabilities of these custom EPP foam packages have led to a marked decrease in product damage during transit, thereby enhancing customer satisfaction and reducing waste.

Another notable case study is that of a mid-sized electronics company that transitioned to custom EPP foam packaging for their sensitive products. The company faced challenges with traditional packaging materials, which were either too heavy or lacked the necessary protection. By switching to lightweight EPP packaging solutions, they observed a substantial reduction in shipping costs due to the lower weight and volume of the packages. Additionally, the superior protective qualities of the EPP foam significantly decreased the rate of damaged goods upon delivery. This switch not only improved the company’s bottom line but also bolstered their reputation for delivering high-quality products in perfect condition, leading to increased customer loyalty and repeat business. These success stories underscore the transformative impact of EPP foam packaging solutions in various sectors, demonstrating their versatility and effectiveness as a sustainable and cost-efficient alternative to traditional packaging materials.

Innovative Lightweight EPP Packaging Strategies for Efficient Logistics

Companies in various sectors are increasingly turning to expanded polypropylene (EPP) molded foam packaging as a solution for their shipping and logistics needs. EPP, known for its strength-to-weight ratio and environmental sustainability, offers a viable alternative to heavier packaging materials. In the realm of efficient logistics, lightweight EPP packaging solutions stand out for their exceptional performance. These solutions are not only cost-effective due to reduced transportation expenses but also contribute to a more streamlined operation, as they are easily stackable and can be designed to fit various product dimensions precisely. As an EPP molded foam packaging supplier with operations in Holland, Ohio, businesses can leverage the expertise of this region’s providers to customize their packaging needs. The ability to tailor EPP foam packaging to specific product requirements means that protection during transit is optimized without unnecessary weight, making handling and storage more manageable. Furthermore, these custom lightweight solutions ensure that products arrive intact, reducing the likelihood of damage and the associated costs of returns or delays. For businesses looking for a dependable supplier of EPP foam packaging, the expertise available in Holland, Ohio, is a testament to the region’s commitment to innovation and customer satisfaction. The strategic location of this supplier also facilitates timely delivery and supports the broader goals of sustainable logistics.