Exploring the intricacies of infrastructure maintenance, this article delves into the transformative role of partial-depth milling in roadway repair. Pavement milling and grinding operations have significantly evolved over the years, with Toledo, Ohio exemplifying their impact on urban infrastructure. We’ll traverse the benefits of these techniques, examine the latest equipment and technology driving efficiency and precision, and review best practices for successful project execution. Additionally, insights from a local case study will highlight the practical advantages of pavement milling and grinding in Toledo, Ohio. As we look to the future, advancements promise to further enhance this essential aspect of road maintenance, keeping cities like Toledo moving smoothly. Join us as we investigate the multifaceted world of pavement milling and grinding.

- Understanding Pavement Milling and Grinding: An Overview

- The Role of Pavement Milling and Grinding in Toledo, Ohio's Infrastructure Maintenance

- Benefits of Partial-Depth Milling Techniques for Roadway Repairs

- Equipment and Technology in Modern Pavement Milling and Grinding Operations

- Best Practices for Executing Partial-Depth Milling Projects

- Case Study: Pavement Milling and Grinding Applications in Toledo, Ohio

- Future Trends and Advancements in Pavement Milling and Grinding Technology

Understanding Pavement Milling and Grinding: An Overview

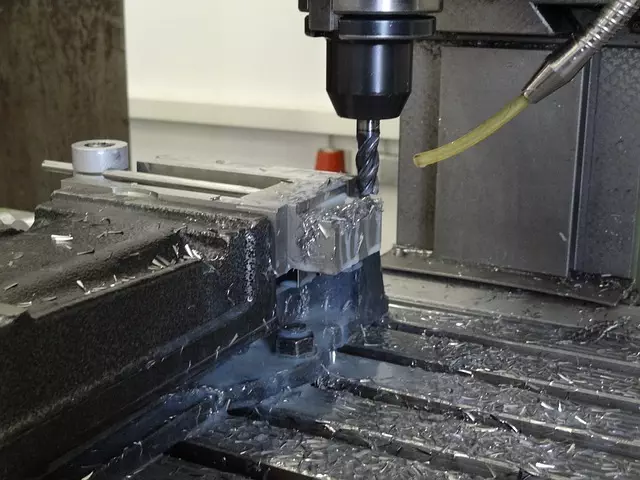

Pavement milling and grinding are essential processes in road maintenance and infrastructure development, serving as both a rehabilitation and preventive measure for roadways. These techniques involve the removal of the surface course or layers of an existing pavement to repair deficiencies, resurface roads, or prepare the pavement for overlay applications. The equipment used for pavement milling and grinding, such as milling machines, can precisely control the depth and pattern of the material removed, ensuring a smooth and level surface for new paving. This process is critical for maintaining the structural integrity of roadways and for enhancing safety by removing deteriorated or unsafe pavement sections.

In Toledo, Ohio, the application of pavement milling and grinding is carried out with meticulous attention to detail, reflecting the city’s commitment to infrastructure quality. The local departments of transportation and contractors are well-versed in these techniques, utilizing state-of-the-art machinery to perform precise cuts at varying depths. This ensures that the milled material can be effectively reused or recycled, minimizing environmental impact and promoting sustainable construction practices. Additionally, the precision of the grinding process helps in achieving a uniform pavement surface, which is crucial for vehicles’ performance and driver safety. The expertise and dedication to this craft in Toledo underscore the importance of pavement milling and grinding as a vital component of roadway maintenance and infrastructure renewal.

The Role of Pavement Milling and Grinding in Toledo, Ohio's Infrastructure Maintenance

Pavement milling and grinding plays a critical role in maintaining the integrity and functionality of Toledo, Ohio’s infrastructure. This process involves the precise removal of the asphalt surface layer from roads, highways, and other paved surfaces to various depths. In Toledo, this method is employed to address issues such as pavement distresses, resurfacing needs, and maintenance work that are essential for safe travel and long-term road health. The milled material is then repurposed or disposed of responsibly, with the resulting smooth surface providing a reliable platform for traffic. The city’s Department of Transportation utilizes advanced equipment to perform these operations efficiently, ensuring minimal disruption to commuters while enhancing road safety and performance. This proactive approach not only extends the lifespan of Toledo’s roads but also facilitates the implementation of new technologies and improvements in traffic flow. The effectiveness of pavement milling and grinding in Toledo is evident in the smooth, consistent driving surfaces that drivers encounter daily, a testament to the city’s commitment to infrastructure maintenance.

The practice of pavement milling and grinding in Toledo is not only about repairs but also about preparing the roadbed for future construction projects. This process allows for the precise removal of damaged asphalt, which is then replaced with new, high-quality material. This ensures a uniform and durable surface that can withstand the demands of daily vehicular traffic. Moreover, the ability to mill specific sections of pavement enables targeted maintenance work, reducing the need for complete road overhauls. The precision and adaptability of this method make it an indispensable tool in Toledo’s ongoing efforts to maintain a robust and reliable transportation network. The city’s investment in this infrastructure upkeep not only supports economic activity but also enhances the quality of life for its residents by ensuring safe and efficient travel on its roads.

Benefits of Partial-Depth Milling Techniques for Roadway Repairs

Equipment and Technology in Modern Pavement Milling and Grinding Operations

Best Practices for Executing Partial-Depth Milling Projects

Partial-depth milling is a specialized process within pavement milling and grinding that involves removing specific layers of the pavement structure to maintain or resurface roadways efficiently. When executing partial-depth milling projects, it is crucial to adhere to best practices to ensure the longevity and quality of the finished surface. Preparation is key; this includes thorough inspection of the pavement, precise planning of the milling pattern, and ensuring that all equipment is well-maintained and calibrated for the specific depths required.

In Toledo Ohio, as in other regions, pavement milling and grinding operations must contend with varying subsurface conditions and weather challenges. To achieve optimal results, it is essential to consider the environmental factors and seasonal variations that can affect the milling process. Employing advanced technology for machine control and saw cutting ensures precision and minimizes the potential for structural weaknesses in the pavement. Additionally, utilizing high-quality diamond tooling and monitoring the dust and debris management during the operation are critical components of best practices. By following these guidelines, contractors can deliver safe, durable, and smoothly finished roadways that meet or exceed performance expectations.

Case Study: Pavement Milling and Grinding Applications in Toledo, Ohio

Pavement milling and grinding are critical maintenance processes in the management of road infrastructure. These operations remove a specified layer or depth of the pavement surface to correct defects, prepare for resurfacing, or maintain traffic safety. In Toledo, Ohio, these techniques have been effectively implemented to address the unique challenges faced by its pavements, which often include weather-related damage and heavy vehicular traffic. The city has utilized pavemill equipment to perform partial-depth milling, a process that precisely removes damaged asphalt without the need for complete pavement removal. This method significantly reduces construction time and associated costs when compared to full-depth reclamation or mill and overlay projects. The precision of the machinery allows for targeted repairs, minimizing disruptions to traffic flow and ensuring a smoother and more durable road surface post-repair.

The applications of pavement milling and grinding in Toledo have been diverse, ranging from routine maintenance on city streets to complex infrastructure rehabilitation projects. The city’s Department of Transportation has leveraged this process to extend the life of its roads, enhance safety by removing slippery or hazardous materials, and improve ride quality. By adopting advanced milling techniques, Toledo has demonstrated a commitment to maintaining high standards in road maintenance, which not only contributes to the longevity of its pavements but also supports the overall economic vitality of the city by ensuring reliable transportation infrastructure for businesses and residents alike. The success of these applications underscores the importance of pavement milling and grinding as a cost-effective, efficient, and sustainable approach to road maintenance, particularly in regions with dynamic traffic demands and seasonal weather challenges.

Future Trends and Advancements in Pavement Milling and Grinding Technology

As the field of pavement milling and grinding continues to advance, innovations are expected to enhance efficiency, precision, and sustainability in Toledo, Ohio, and beyond. Future trends in this sector suggest a shift towards more automated and intelligent systems that can adapt to varying pavement conditions. The integration of advanced sensors and machine learning algorithms promises to optimize the milling process, ensuring smoother surfaces and better alignment with underlying infrastructure. These technologies will likely reduce the time required for pavement milling and grinding, minimizing traffic disruptions and improving project timelines. Moreover, the industry is moving towards more environmentally friendly practices, with an emphasis on recycling milled materials directly into new pavements, thereby reducing waste and lowering the carbon footprint associated with these operations. The evolution of pavement milling and grinding technology in Toledo, Ohio, reflects a broader trend towards smarter, greener, and more efficient construction methods that align with both industry standards and environmental regulations. Contractors specializing in pavement milling and grinding are increasingly adopting cutting-edge solutions that combine durability with cost-effectiveness, ensuring that infrastructure projects meet the high demands of today’s transportation networks while laying the groundwork for future advancements in the field.