The article discusses the crucial role of pavement milling and grinding in Toledo, Ohio's road maintenance and infrastructure development. This process involves precise removal of damaged asphalt layers using advanced machinery equipped with cutting drums and carbide-tipped teeth to ensure uniform chip size. These machines are designed for maneuverability and effectiveness, incorporating modern technologies like laser guidance systems for precision in grade and slope adjustments. The industry's focus on sustainability is evident, with Toledo facilities recycling the milled asphalt into new pavements, thus supporting a circular economy and minimizing environmental impact. This approach not only improves road quality but also enhances the longevity of infrastructure, reducing traffic disruptions and project timelines compared to traditional methods. The article emphasizes the importance of this sustainable technology in Toledo's urban infrastructure strategy, highlighting its environmental benefits and cost-effectiveness.

Exploring the intricacies of pavement milling and grinding offers a glimpse into the dynamic world of infrastructure maintenance. This article delves into the various techniques and their local impact, particularly in Toledo, Ohio. From understanding the mechanics of asphalt grinding machines to examining the environmental considerations, we’ll cover the benefits, preparation strategies, and innovative advances that shape this essential practice. Join us as we navigate the key role pavement milling and grinding plays in preserving our roadways and communities.

- Understanding Pavement Milling and Grinding: An Overview

- The Mechanics of Asphalt Grinding Machines: A Technical Insight

- Benefits of Pavement Milling and Grinding in Infrastructure Maintenance

- Pavement Milling and Grinding to Toledo, Ohio: Local Application and Impact

- Preparation and Planning for Effective Pavement Milling Operations

- The Environmental Considerations of Asphalt Grinding

- Innovative Advances in Pavement Milling and Grinding Techniques

Understanding Pavement Milling and Grinding: An Overview

Pavement milling and grinding are critical processes in road maintenance and construction, serving as a foundational step for various pavement improvement projects. These techniques involve the removal of the surface layer of an asphalt pavement to correct its thickness, remove damage, or prepare it for resurfacing. The process begins with the selection of appropriate equipment, such as milling machines, which can be mounted with different tooth configurations depending on the depth and condition of the material to be removed. The grinding phase follows, where a grinding train equipped with either fixed or rotating teeth grinds the exposed asphalt into smaller pieces, ensuring a smooth and uniform base for subsequent work. This meticulous process not only enhances pavement longevity but also improves safety by addressing defects such as rutting, shoving, or irregularities that can compromise vehicle and pedestrian traffic.

In the realm of specialized services, some companies have honed their expertise in pavement milling and grinding, with Toledo Ohio being a testament to their presence and proficiency. Local infrastructure projects often utilize these services to maintain the integrity of roadways and ensure compliance with specifications for new asphalt overlays or maintenance activities. The precision and efficiency of local crews are essential for timely project completion, minimizing disruptions to traffic flow, and upholding the high standards required for public roadways in this region. These operations are integral to the ongoing cycle of maintenance that extends the lifespan of our transportation networks, making them safe and reliable for all users.

The Mechanics of Asphalt Grinding Machines: A Technical Insight

Asphalt grinding is a critical process in road maintenance and infrastructure development, known in the industry as pavement milling and grinding. This technique involves the precise removal of asphalt layers from a pavement structure to prepare for repairs, resurfacing, or the creation of new roadways. The machinery employed in pavement milling and grinding operations is sophisticated and designed to achieve optimal performance under various conditions.

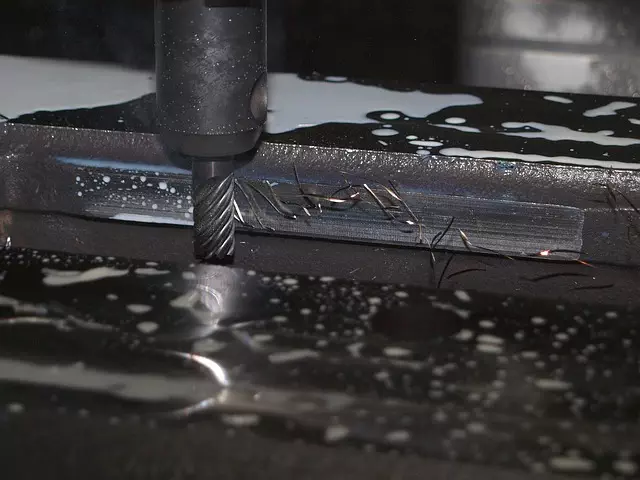

The process commences with an adjustable cutting drum, typically equipped with carbide-tipped teeth, which rotates at high speeds to cut the asphalt into uniform chips. The drum’s size and tooth configuration can be tailored based on the depth of material to be removed, ranging from a few millimeters to several inches. As the cutting drum performs its task, the debris is simultaneously conveyed into a collection system by a set of conveyor belts or a vacuum system, ensuring minimal disruption and efficient cleanup. The entire assembly is mounted upon a mobile base, often with steerable axles for maneuverability around complex job sites. In regions like Toledo, Ohio, where the pavement milling and grinding industry is active, these machines undergo rigorous maintenance and upkeep to ensure they can handle the diverse challenges of the region’s infrastructure projects. The technology behind these machines, including their robust motors, sophisticated control systems, and precise mechanisms for adjusting cutting depth and speed, reflects a deep understanding of both the material properties of asphalt and the dynamics of heavy machinery operation. This ensures that pavement milling and grinding operations can be carried out swiftly and effectively, minimizing project timelines and contributing to the efficiency and longevity of road infrastructure systems.

Benefits of Pavement Milling and Grinding in Infrastructure Maintenance

Pavement milling and grinding are indispensable processes in modern infrastructure maintenance, offering a range of benefits that enhance roadway conditions and extend their usable lifespan. These techniques involve removing the surface layer or selected areas of asphalt pavement through controlled milling and grinding operations. The resulting material can be reused, significantly reducing the environmental impact associated with complete pavement removal and replacement. In Toledo, Ohio, for instance, these methods are employed to address pavement distresses such as rutting, cracking, or surface wear, ensuring a smoother, safer driving experience. The precision of milling and grinding equipment allows for the precise removal of only the damaged layer, preserving the integrity of the underlying structure. This targeted approach minimizes disruptions to traffic flow and reduces project timelines compared to traditional rehabilitation methods. Furthermore, the reground asphalt can be recycled into new pavements, supporting sustainable construction practices and contributing to the circular economy. The consistent quality of the pavement surface achieved through milling and grinding also facilitates better adherence for new asphalt overlays, which in turn improves the overall performance and longevity of the road infrastructure. These processes are not only cost-effective but also provide a high-quality finish that meets or exceeds original pavement specifications. In Toledo, Ohio, where the demand for reliable and well-maintained roads is high, pavement milling and grinding have become a cornerstone of effective infrastructure maintenance, demonstrating their value in both urban and rural settings.

Pavement Milling and Grinding to Toledo, Ohio: Local Application and Impact

In urban infrastructure maintenance, pavement milling and grinding plays a pivotal role in roadway reconstruction and rehabilitation. This process involves removing the top layer of asphalt from a paved area to prepare for repairs or resurfacing. In Toledo, Ohio, this technique is employed with particular frequency and precision to address the unique challenges of its road network. The city’s Department of Transportation utilizes advanced pavement milling and grinding equipment to efficiently remove damaged asphalt, ensuring a smooth base for new paving materials. This not only extends the lifespan of the roads but also enhances safety and driving comfort for Toledo’s commuters.

The local application of pavement milling and grinding in Toledo is not without its impact. The process contributes to the city’s efforts to maintain a high standard of road quality, which is crucial for both everyday transportation and emergency response. Moreover, the recycled asphalt produced from this process is often reused in new paving projects, promoting sustainability and environmental stewardship. This closed-loop system not only reduces the demand for virgin materials but also minimizes the environmental footprint associated with road maintenance. The impact of pavement milling and grinding on Toledo’s infrastructure is thus both immediate and enduring, ensuring that the city’s roads remain in optimal condition for residents and travelers alike.

Preparation and Planning for Effective Pavement Milling Operations

When executing pavement milling and grinding operations, meticulous preparation and strategic planning are paramount for achieving optimal results. Effective project management begins with a thorough assessment of the pavement condition, traffic patterns, and the specific goals of the milling operation. Understanding the scope of work involves determining the depth to which material must be removed, the size and type of milling equipment required, and the appropriate timing for these activities to minimize disruption.

In Toledo, Ohio, as in many regions, the process of pavement milling and grinding demands compliance with local regulations and environmental considerations. Contractors must navigate these operations with precision, utilizing advanced machinery that can adapt to various pavement types and conditions. The selection of the right milling machine is critical; machines come in different sizes and configurations, suitable for milling a range of asphalt layers from thin overlays to full-depth removal. Preparatory measures also include ensuring the crew is well-trained, equipped with safety gear, and that contingency plans are in place should unexpected challenges arise. Coordination with local authorities and stakeholders is essential to ensure that the milling operations align with traffic control requirements and maintain the flow of vehicular and pedestrian traffic during the process. By prioritizing these elements, contractors can conduct pavement milling and grinding operations efficiently and effectively in Toledo, Ohio, contributing to the longevity and safety of roadways.

The Environmental Considerations of Asphalt Grinding

Asphalt grinding, a process often referred to as pavement milling, plays a crucial role in road maintenance and construction. This method involves removing a specified layer of the existing pavement surface through controlled sawing and grinding operations. Environmental considerations are paramount when undertaking such projects, as they directly impact air quality, noise pollution, and resource management. The finely ground asphalt produced during pavement milling can be recycled into new pavement, significantly reducing the need for virgin materials and minimizing landfill use. This practice not only conserves natural resources but also contributes to the sustainability of infrastructure development.

In regions like Toledo, Ohio, where pavement milling and grinding are regularly employed, environmental agencies set stringent guidelines to mitigate potential negative impacts. These guidelines ensure that emissions from the grinding equipment are kept at a minimum, often through the use of modern, cleaner technology. Additionally, the fine particles generated during the process are collected with dust suppressants to prevent airborne pollution. The collection and reuse of these materials also eliminate the need for new asphalt production, which is energy-intensive and emits greenhouse gases. As a result, pavement milling and grinding in Toledo adheres to environmentally friendly practices that support the local ecology and contribute to the health and well-being of the community.

Innovative Advances in Pavement Milling and Grinding Techniques

The field of pavement milling and grinding has seen significant advancements in recent years, significantly enhancing the efficiency and precision of infrastructure maintenance. Traditional methods have been refined and augmented with new technologies that not only improve the quality of work but also minimize disruptions to traffic and surrounding environments. For instance, the integration of advanced laser guidance systems has enabled operators to achieve higher levels of accuracy, ensuring that the milled material meets specific grade and slope requirements. These sophisticated systems provide real-time feedback, allowing for immediate adjustments during the operation.

In addition to technological improvements, there is a growing emphasis on sustainable practices within pavement milling and grinding operations. Facilities like those in Toledo, Ohio have been at the forefront of this shift, adopting eco-friendly methods that recycle the milled asphalt directly on-site. This not only reduces the environmental impact but also creates a cost-effective recycled material that can be used for less critical repairs or new construction projects. The adoption of these innovative techniques underscores the industry’s commitment to sustainability while maintaining high standards of service and infrastructure quality.