OSHA workplace safety inspections are crucial for employee well-being and industry standards adherence. Trained professionals use standardized hazard assessment protocols to evaluate equipment maintenance, PPE usage, SDS compliance, and training records. This process encourages proactive risk management, updates safety protocols, addresses hazards, and educates employees, reducing accidents and enhancing productivity. Effective hazard assessment protocols, which go beyond SDS regulations, guide auditors in identifying and mitigating risks. Verifying up-to-date SDSs during audits fosters safety consciousness. Integrating technology revolutionizes inspections with digital tools for real-time data analysis. Regular training empowers employees to conduct risk evaluations, fostering a proactive safety culture. Analyzing audit findings through hazard assessment protocols reveals compliance gaps and drives targeted corrective actions, ultimately enhancing OSHA compliance and workplace safety.

In today’s competitive landscape, continuous improvement in safety audits is paramount. This article delves into essential aspects of OSHA workplace safety inspections, providing a robust foundation for enhancing industrial safety standards. We explore the pivotal role of hazard assessment protocols in streamlining audit processes and emphasize the critical importance of Safety Data Sheet (SDS) compliance for effective risk mitigation. Additionally, we discuss integrating technology and promoting employee training to foster a proactive safety culture, backed by data-driven decisions from measured audit findings.

- Understanding OSHA Workplace Safety Inspections: A Foundation for Continuous Improvement

- The Role of Hazard Assessment Protocols in Enhancing Safety Audit Processes

- Safety Data Sheet (SDS) Compliance: A Crucial Aspect of Risk Mitigation

- Integrating Technology for Efficient and Effective Safety Audits

- Training and Education: Empowering Employees for Proactive Safety Culture

- Measuring and Analyzing Audit Findings for Data-Driven Decisions

Understanding OSHA Workplace Safety Inspections: A Foundation for Continuous Improvement

OSHA workplace safety inspections are a crucial aspect of ensuring employee well-being and adherence to industry standards. These inspections, conducted by trained professionals, involve thorough assessments of the work environment, focusing on potential hazards and compliance with safety regulations. By employing standardized hazard assessment protocols, organizations can identify risks and implement effective control measures, fostering a culture of continuous improvement in workplace safety.

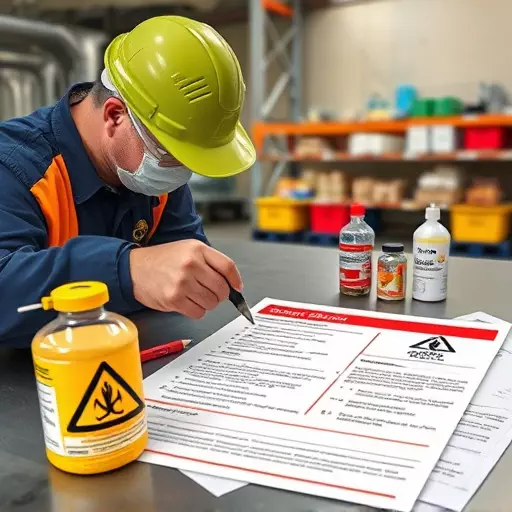

During these inspections, examiners review various factors, including equipment maintenance, personal protective equipment (PPE) usage, safety data sheet (SDS) compliance, and training records. The process encourages proactive risk management by prompting businesses to regularly update their safety protocols, address identified hazards, and educate employees on best practices. This continuous improvement approach not only reduces the likelihood of accidents and injuries but also enhances overall operational efficiency and productivity in the long run.

The Role of Hazard Assessment Protocols in Enhancing Safety Audit Processes

Effective hazard assessment protocols are instrumental in bolstering safety audit processes, as they provide a structured framework for identifying and mitigating potential risks within the workplace. These protocols, often mandated by organizations like OSHA (Occupational Safety and Health Administration), go beyond mere compliance with safety data sheet (SDS) regulations. By meticulously evaluating work environments, equipment, procedures, and employee practices, hazard assessment protocols ensure that no stone is left unturned during safety inspections.

Through systematic risk assessments, these protocols help in pinpointing areas where workplace safety can be enhanced. They guide auditors in gathering relevant data, analyzing potential hazards, and making informed recommendations for improvement. By adhering to established protocols, safety audit processes become more efficient, comprehensive, and effective in upholding OSHA standards, ultimately fostering a culture of continuous improvement in workplace safety inspections.

Safety Data Sheet (SDS) Compliance: A Crucial Aspect of Risk Mitigation

In the realm of OSHA workplace safety inspections, ensuring thorough and consistent Safety Data Sheet (SDS) compliance is a pivotal strategy for risk mitigation. SDSs serve as comprehensive guides that detail the potential hazards associated with specific chemicals or substances used in various industries. By adhering to established hazard assessment protocols during audits, organizations can effectively identify, classify, and communicate these risks to employees and stakeholders alike. This proactive approach not only facilitates informed decision-making but also fosters a culture of safety consciousness within the workplace.

During safety audits, meticulous scrutiny of SDS documentation is paramount. Auditors should verify that each chemical’s SDS is up-to-date, readily accessible, and accurately reflects the substance’s current hazards and safe handling procedures. Inadequate or outdated SDSs can lead to misinformed responses during emergencies or routine operations, potentially exacerbating risks. Thus, continuous updates and adherence to industry standards are essential components of a robust safety management system, ensuring that all personnel are equipped with the knowledge necessary to maintain a secure working environment.

Integrating Technology for Efficient and Effective Safety Audits

Integrating technology has significantly transformed OSHA workplace safety inspections, making them more efficient and effective. Digital tools can streamline hazard assessment protocols by providing real-time data and insights, enabling inspectors to quickly identify potential risks and document findings with precision. For instance, mobile apps allow for instant reporting of violations and unsafe conditions, while digital versions of Safety Data Sheets (SDS) ensure easy access to critical information during audits.

This technological advancement enhances overall safety compliance by automating repetitive tasks, reducing human error, and facilitating better data analysis. With advanced analytics, trends in workplace hazards can be identified more readily, allowing for proactive measures to mitigate risks before they escalate. As a result, organizations are better equipped to meet regulatory standards and foster a culture of continuous improvement in OSHA workplace safety inspections.

Training and Education: Empowering Employees for Proactive Safety Culture

Training and education play a pivotal role in fostering a proactive safety culture within any organization. Employees are the front line in identifying potential hazards, implementing safe practices, and ensuring continuous improvement during OSHA workplace safety inspections. Regular training sessions on hazard assessment protocols can equip workers with the skills to conduct thorough risk evaluations, identify near-misses, and report safety concerns. This empowers them to take ownership of their safety and that of their colleagues.

Furthermore, educating employees about safety data sheet (SDS) compliance is essential. Understanding the proper handling, storage, and disposal of hazardous materials as outlined in SDS documents can prevent accidents and promote a safer work environment. By investing in comprehensive training programs, companies can create a culture where safety isn’t just a priority but an inherent part of every employee’s mindset.

Measuring and Analyzing Audit Findings for Data-Driven Decisions

In the realm of OSHA workplace safety inspections, continuous improvement hinges on measuring and analyzing audit findings. By systematically documenting and evaluating hazards identified during inspections, organizations can gain valuable insights into their compliance status with regard to critical standards and regulations, including safety data sheet (SDS) compliance. This data-driven approach allows for a more strategic focus on areas requiring enhancement, ensuring resources are allocated efficiently to mitigate risks effectively.

Effective hazard assessment protocols play a pivotal role in this process. These protocols facilitate a thorough examination of workplace conditions, equipment, and procedures, uncovering potential hazards that may not be immediately apparent. The data collected during these assessments serves as a foundation for informed decision-making. Organizations can leverage this information to implement targeted corrective actions, update safety protocols, and enhance overall OSHA compliance, ultimately fostering a safer work environment.