Anti-static foam inserts, custom-made in Holland, Ohio, are essential for protecting automotive components during shipping. These specialized foams fit specific part dimensions, minimize electrostatic discharge, and prevent physical damage, ensuring the safe transport of delicate parts and enhancing customer satisfaction. Businesses in Holland offer advanced customization, including various materials and shapes, to cater to unique car models and protect against environmental stressors, making them a vital industry solution for fragile automotive parts shipping.

“Anti-static foam inserts have become indispensable in the electronics and automotive industries, offering unparalleled protection for delicate components. This article explores the multifaceted role of these innovative solutions, from enhancing product safety to optimizing shipping processes. We delve into the benefits of custom automotive foam inserts for specific applications, focusing on Holland, Ohio, and provide best practices for utilizing foam inserts to safeguard fragile automotive parts during transit.”

- Understanding Anti-static Foam Inserts for Electronics: Their Role and Benefits

- Customization Options for Automotive Foam Inserts in Holland, Ohio

- Best Practices for Using Foam Inserts to Ship Fragile Automotive Parts Safely

Understanding Anti-static Foam Inserts for Electronics: Their Role and Benefits

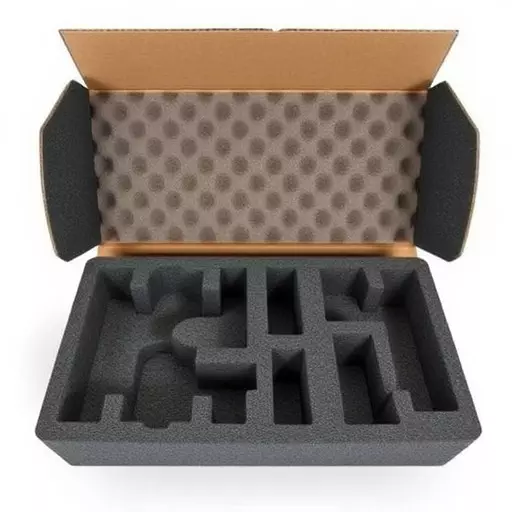

Anti-static foam inserts play a crucial role in protecting delicate electronic components during shipping and storage. These specialized foams are designed to minimize electrostatic discharge (ESD), which can cause significant damage or even render devices useless. In the automotive industry, where precision electronics are increasingly integrated into modern vehicles, anti-static foam inserts are essential for ensuring the safe transport of fragile parts. Custom automotive foam inserts, tailored to fit specific part dimensions, offer optimal protection by conforming to irregular shapes and preventing movement during transit.

For auto manufacturers in Holland, Ohio, and beyond, investing in custom automotive foam inserts is a strategic move to safeguard valuable assets. By encapsulating electronic components within anti-static foam, these parts are less likely to experience ESD events, which can occur due to everyday activities like handling or exposure to ground shocks. This proactive approach not only reduces the risk of product failure but also contributes to higher product quality and consistency, ultimately enhancing customer satisfaction. Additionally, proper packing with anti-static foam inserts can extend the lifespan of automotive electronics by protecting them from physical impacts and environmental stressors during shipping.

Customization Options for Automotive Foam Inserts in Holland, Ohio

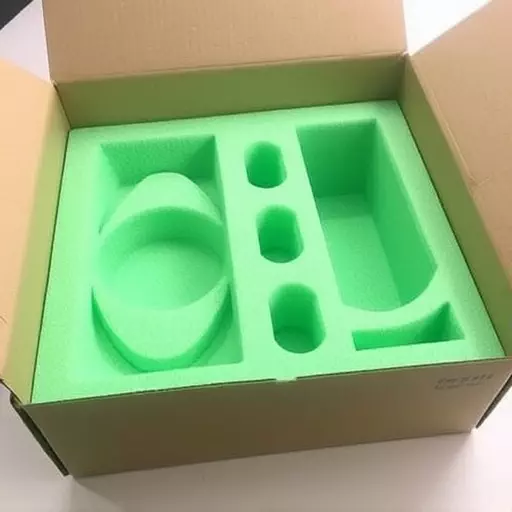

In Holland, Ohio, businesses specializing in automotive foam inserts offer a range of customization options to cater to specific needs. These custom automotive foam inserts are designed with precision to protect fragile automotive parts during shipping and handling. By utilizing advanced manufacturing techniques, these companies can create foam inserts that perfectly fit unique car models, ensuring maximum protection for every component.

Whether you require foam inserts for shipping delicate electronic parts or safeguarding classic car collectibles, local providers in Holland, Ohio, have the expertise to deliver tailored solutions. Their customization capabilities include various materials, densities, and shapes, allowing them to accommodate specific requirements for fragile automotive parts. This level of personalization ensures that every package is securely padded, minimizing the risk of damage during transit.

Best Practices for Using Foam Inserts to Ship Fragile Automotive Parts Safely

When shipping fragile automotive parts, such as custom car dashboards or intricate engine components, utilizing anti-static foam inserts is a best practice that can significantly reduce damage during transit. These specialized inserts, often crafted in Holland, Ohio, are designed to create a protective cushion around the parts, minimizing movement and preventing contact with sharp edges or other objects. By encapsulating each component in a tailored piece of foam, you ensure that even the most delicate automotive parts arrive at their destination intact.

For optimal results, consider custom automotive foam inserts that are meticulously measured and cut to fit your specific part. This precise approach eliminates excess material that could shift during shipping, further securing the components in place. Additionally, anti-static properties prevent electrostatic discharge, which can be detrimental to sensitive electronic components within the automotive parts. Effective use of these foam inserts not only safeguards valuable inventory but also demonstrates a commitment to quality and customer satisfaction.