Automotive foam inserts, custom-made to fit specific part dimensions, offer unparalleled protection for fragile components during shipping and handling, especially crucial for high-value or specialized parts in Holland, Ohio. High-density foam, known for its compressibility and impact-absorbing abilities, is widely used to safeguard sensitive automotive parts like electronics and glass. Custom inserts, designed through collaboration between manufacturers and companies, prioritize safety by optimizing space and preventing damage from shifting during transport. Businesses in Holland, Ohio can leverage these inserts to reduce repair costs and choose sustainable options for long-term savings and environmental concerns.

“Unveiling the Secret to Secure Shipping: High-Density Foam Inserts for Automotive Components

In the realm of automotive care and logistics, understanding the role of foam inserts is a game-changer. This article delves into the world of custom automotive foam inserts, their benefits, and applications in ensuring fragile parts’ safety during shipping. From high-density foam materials to customization options, we explore how these inserts revolutionize protection.

Discover the advantages, learn about design processes, and gain insights into choosing the ideal inserts for various automotive components, all tailored to meet the specific needs of Holland, Ohio’s shipping industry.”

- Understanding Automotive Foam Inserts: Their Role and Benefits

- High-Density Foam: A Closer Look at the Material

- Customization Options for Automotive Foam Inserts

- Applications of Automotive Foam Inserts in Shipping and Protection

- Choosing the Right Foam Insert for Different Fragile Parts

- The Process of Designing and Creating Custom Automotive Foam Inserts

- Advantages and Considerations for Using High-Density Foam Inserts

Understanding Automotive Foam Inserts: Their Role and Benefits

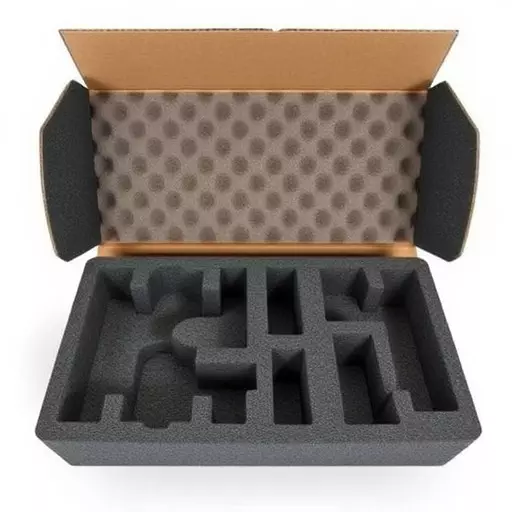

Automotive foam inserts are specialized materials designed to protect and support various components within vehicles. These inserts play a crucial role in ensuring the safe transportation of automotive parts, especially during shipping and handling. By understanding their function, we can appreciate the benefits they bring to the automotive industry.

Custom automotive foam inserts are tailored to fit specific part dimensions, offering superior protection for fragile items. In Holland, Ohio, and beyond, these inserts are widely used in the shipping process, minimizing the risk of damage to delicate automotive components. Their primary benefit lies in shock absorption, where they act as a buffer between parts, preventing bumps and vibrations from causing harm. This is particularly essential when shipping high-value or specialized automotive parts across long distances.

High-Density Foam: A Closer Look at the Material

High-density foam is a versatile material that has found its niche in various industries, including the automotive sector. When it comes to automotive components, this type of foam offers an exceptional combination of lightweight construction and remarkable strength, making it ideal for multiple applications. It is particularly valuable for protecting fragile parts during shipping and handling due to its ability to absorb impact and distribute force evenly.

Custom automotive foam inserts are a prime example of how high-density foam is tailored to specific requirements. By designing these inserts, manufacturers can ensure precise fitting within various vehicle compartments, maximizing the protection of sensitive components like electronics, glass parts, and delicate mechanical assemblies. With its exceptional compressibility and recovery properties, high-density foam provides the perfect cushion for automotive foam inserts for shipping in Holland, Ohio, or anywhere else, ensuring that fragile items arrive safely at their destination.

Customization Options for Automotive Foam Inserts

When it comes to customizing automotive foam inserts, the possibilities are vast. For shipping and packaging in Holland, Ohio, businesses can select from a wide array of options tailored to their specific needs. Custom automotive foam inserts allow for precise protection of fragile automotive parts during transit, ensuring they arrive safe and sound. These inserts can be designed with unique shapes and sizes to accommodate various components, from delicate electronic systems to intricate mechanical parts.

The customization process involves close collaboration between the manufacturer and the automotive company to understand the dimensions, weight, and fragility of the parts. Advanced manufacturing technologies enable the creation of foam inserts that precisely fit these requirements. By utilizing specialized materials and cutting-edge machinery, custom automotive foam inserts can be produced to offer superior protection while optimizing space utilization within the shipping container.

Applications of Automotive Foam Inserts in Shipping and Protection

Automotive foam inserts have become indispensable in the shipping and protection of various components due to their exceptional properties. These high-density foam materials are custom-designed to fit specific parts, ensuring a snug and secure hold during transit. Whether it’s protecting delicate electronic systems or fragile glass components, automotive foam inserts play a vital role in maintaining the integrity of these parts.

In Holland, Ohio, and beyond, custom automotive foam inserts are sought after for their versatility. They can be crafted to accommodate unique shapes and sizes, making them ideal for shipping rare or specialized automotive parts. This level of customization not only guarantees the safety of fragile items but also optimizes space utilization within shipping containers, reducing potential damage from shifting during transport.

Choosing the Right Foam Insert for Different Fragile Parts

When selecting the right foam insert for different fragile automotive parts, it’s crucial to consider the specific needs and vulnerabilities of each component. Custom automotive foam inserts offer a tailored solution, ensuring that delicate items like glass, sensors, or electronics are protected during shipping and storage in Holland, Ohio. These inserts can be designed with specific shapes and densities to accommodate unique part sizes and weights, providing optimal shock absorption and minimizing movement within the packaging.

For instance, soft, low-density foam might be suitable for wrapping fragile glass components, while denser foams with higher compression resistance could better protect heavier parts prone to intense impacts. By understanding the part’s characteristics and choosing the corresponding foam insert, manufacturers can ensure that their automotive components arrive at their destination in top condition, reducing damage and maintenance costs.

The Process of Designing and Creating Custom Automotive Foam Inserts

The process of designing and creating custom automotive foam inserts involves a blend of precision engineering and material science. It starts with understanding the specific needs of the client, including dimensions, weight requirements, and protection levels needed for various fragile automotive parts. Engineers then use computer-aided design (CAD) software to create detailed 3D models of the inserts, ensuring they perfectly fit within the designated spaces in vehicles.

Once the designs are finalized, manufacturers turn to advanced foam fabrication techniques. This includes selecting appropriate materials like high-density polyethene (HDPE) or polypropylene (PP), which offer excellent cushioning and impact resistance. The chosen material is then cut and molded into the desired shape using precision machinery, resulting in custom automotive foam inserts tailored to protect sensitive components during shipping and handling. These inserts are particularly useful for parts shipped from Holland, Ohio, ensuring their integrity and reducing damage during transportation.

Advantages and Considerations for Using High-Density Foam Inserts

High-density foam inserts offer a multitude of advantages when it comes to protecting and securing automotive components during shipping. One of their key benefits is customization; these inserts can be tailored to fit specific parts precisely, ensuring delicate items like glass, mirrors, or custom-built automotive parts are securely nestled in place. This level of customization is particularly valuable for businesses in Holland, Ohio, specializing in shipping fragile automotive parts across long distances. By using high-density foam, they can prevent damage caused by shifting during transit, which is a significant concern for many auto manufacturers and dealers.

When considering the implementation of these foam inserts, several factors come into play. Cost is an initial consideration; while high-density foam may have a higher upfront cost compared to traditional packing materials, its effectiveness in protecting valuable automotive components can lead to long-term savings by reducing damage and associated repair costs. Additionally, the environmental impact should be evaluated, as sustainable foams are available that offer performance without contributing to ecological concerns. For businesses focusing on eco-friendly practices, this is a significant advantage when compared to non-biodegradable packing materials commonly used in the automotive industry.