Custom injection molded packaging solutions from Holland, Ohio, play a pivotal role in safeguarding the integrity and quality of temperature-sensitive goods throughout the global supply chain. These services, provided by experts in professional injection molding, offer tailored packaging that ensures product safety against environmental factors, including temperature changes and physical impacts during transport. The benefits of using Holland's injection molded packaging include precise design, durability, effective insulation properties, cost-effectiveness, and sustainable materials, all contributing to the longevity and protection of sensitive goods like pharmaceuticals, food products, and electronics. These bespoke containers are engineered for optimal performance, offering a balance between environmental resilience and product preservation. As evidenced by successful partnerships with leading pharmaceutical and premium food manufacturers, Holland's injection molded packaging has proven to be a critical component in maintaining compliance, reducing waste, and enhancing brand reputation through consistent product quality upon delivery.

Steel containers have long been a cornerstone in the transport and storage of temperature-sensitive goods, offering unparalleled durability and reliability. This article delves into the robust nature of these containers and highlights the expertise of Holland, Ohio, a leading provider of custom injection molded packaging solutions. Explore the myriad benefits of injection molded packaging and how professional services can significantly enhance your supply chain’s efficiency and effectiveness. From maintaining product integrity to showcasing through case studies how these containers excel in temperature-controlled environments, this comprehensive guide underscores the advantages of choosing custom injection molded packaging by Holland, Ohio.

- Exploring the Durability and Reliability of Steel Containers for Temperature-Sensitive Goods

- Custom Injection Molded Packaging by Holland, Ohio: A Comprehensive Overview

- The Advantages of Injection Molded Packaging in Protecting Your Products

- How Professional Injection Molding Services Can Enhance Your Supply Chain

- The Role of Injection Molded Containers in Maintaining Product Integrity

- Case Studies: Success Stories of Injection Molded Packaging in Temperature-Controlled Environments

Exploring the Durability and Reliability of Steel Containers for Temperature-Sensitive Goods

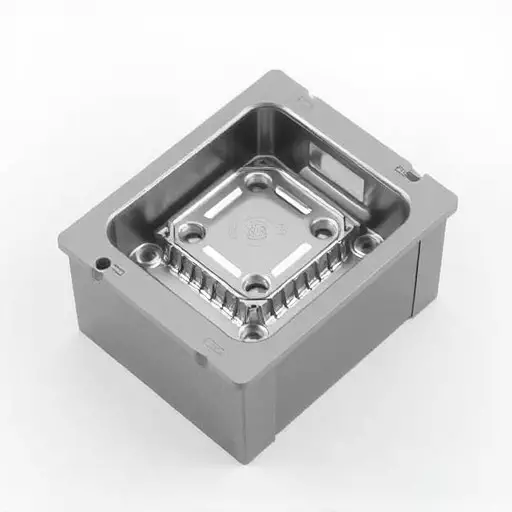

Steel containers have long been a staple in the transportation and storage of goods due to their unparalleled durability and resilience against environmental factors. In the context of temperature-sensitive goods, these containers offer a robust solution that ensures product integrity over extended periods. The thickness and construction of steel containers provide superior insulation properties, making them adept at maintaining consistent internal temperatures despite external climate fluctuations. This is particularly critical for products like pharmaceuticals, food items, and electronics that require precise temperature control to prevent spoilage or degradation.

Custom injection molded packaging manufacturers like those in Holland, Ohio, specialize in designing steel containers tailored to the specific needs of transporting sensitive goods. These professional injection molding services not only ensure a tight seal to regulate temperature but also offer added benefits such as customization, durability, and cost-effectiveness. The advanced technology used in injection molding allows for precise design and repeated production of high-quality containers that can withstand the rigors of transit. This results in a packaging solution that not only protects the contents from temperature variations but also ensures their safety during handling and transportation.

Custom Injection Molded Packaging by Holland, Ohio: A Comprehensive Overview

Companies in Holland, Ohio, that specialize in custom injection molded packaging offer a range of benefits for businesses looking to protect and transport temperature-sensitive goods effectively. These professional injection molding services provide solutions tailored to specific product needs, ensuring optimal protection against environmental factors that could compromise product integrity. The precision and durability of injection molded packaging contribute significantly to the preservation of product quality during transit, which is particularly critical for items that require strict temperature control.

The process of custom injection molding allows for intricate designs and precise dimensions, accommodating the unique specifications of various products. This means that each container can be engineered to provide the best possible fit for its contents, minimizing the risk of damage from shock, vibration, or temperature fluctuations. Moreover, the materials used in these packages are selected not only for their protective properties but also for their sustainability and recyclability, aligning with industry trends towards more eco-conscious packaging solutions. Companies in Holland, Ohio, excel in this niche market, providing a comprehensive range of options that can be customized to meet any requirement for temperature-sensitive goods transportation and storage.

The Advantages of Injection Molded Packaging in Protecting Your Products

In the realm of protecting temperature-sensitive goods during transit, custom injection molded packaging from Holland, Ohio, stands out as a premier solution due to its robust design and precise engineering. This innovative packaging not only safeguards against external temperature fluctuations but also offers superior protection against impacts and vibrations that can compromise product integrity. The professional injection molding services provided ensure that each package is tailored to the exact dimensions and specifications of the goods it encloses, eliminating any risk of product damage. The benefits of injection molded packaging are manifold: it provides an airtight seal to maintain the desired temperature within, resists moisture intrusion, and is resilient against a variety of environmental stressors. This level of customization and protection extends the shelf life of temperature-sensitive products, ensuring they reach their destination in optimal condition. The precision and durability offered by these services are unmatched, making them an indispensable asset for companies that prioritize product safety and quality assurance.

How Professional Injection Molding Services Can Enhance Your Supply Chain

In the realm of supply chain logistics, the protection and efficient delivery of temperature-sensitive goods are paramount to maintain product integrity and customer satisfaction. Utilizing custom injection molded packaging from Holland, Ohio, can significantly bolster this aspect of your operations. Professional injection molding services offer a range of benefits that cater to the unique needs of such products. These bespoke solutions are tailored to withstand various environmental conditions, ensuring that temperature-sensitive goods remain intact and undamaged throughout their journey. The precision and durability of injection molded packaging provide an additional layer of defense against potential thermal fluctuations, which is critical for sensitive items like pharmaceuticals, food products, and electronic components. This not only minimizes the risk of spoilage or damage but also aligns with stringent regulatory standards, thereby safeguarding your brand’s reputation. Furthermore, partnering with a provider in Holland, Ohio, grants access to their expertise and the ability to leverage their strategic location for streamlined distribution across diverse markets. This enhances your supply chain by optimizing transit times and reducing the likelihood of delays or mishandling, ultimately leading to a more robust and reliable system that upholds the quality and security of your goods from origin to destination.

The Role of Injection Molded Containers in Maintaining Product Integrity

In the realm of temperature-sensitive goods, maintaining product integrity from production to delivery is paramount. Custom injection molded packaging from Holland, Ohio, plays a critical role in this process. These containers are engineered to provide unparalleled protection against external factors that could compromise the quality and functionality of temperature-sensitive products. The precision and durability inherent in professional injection molding services ensure that each package is tailored to meet the exact specifications required for its contents, creating a barrier that locks in the desired temperature while safeguarding against environmental fluctuations. This bespoke approach allows for an optimal micro-environment for goods such as pharmaceuticals, food products, and electronics, which are particularly susceptible to temperature variations. The benefits of injection molded packaging extend beyond mere protection; they also facilitate efficient stacking and space utilization, making them a cost-effective solution for businesses aiming to optimize their supply chain logistics. Furthermore, the material used in these containers is typically recyclable and can be designed with insulative properties that are critical for maintaining the intended temperature range throughout the transit process, ensuring that the goods arrive in pristine condition.

Case Studies: Success Stories of Injection Molded Packaging in Temperature-Controlled Environments

In the realm of temperature-sensitive goods packaging, custom injection molded packaging from Holland, Ohio, has emerged as a leading solution in maintaining product integrity within temperature-controlled environments. One notable success story is that of a major pharmaceutical company that successfully mitigated the risks associated with drug degradation by leveraging Holland’s professional injection molding services. The company required robust packaging for its new vaccine, which necessitated precise dimensions and an impenetrable barrier to extreme temperatures. Holland’s custom-designed packaging not only provided these specifications but also enhanced the user experience with its ergonomic design. As a result, the vaccine remained stable throughout the distribution chain, from the manufacturing facility to the final destination, ensuring patient safety and compliance with stringent regulatory standards.

Another compelling case involves a premium food manufacturer aiming to expand its market reach by improving the shelf life of its perishable products. The manufacturer partnered with Holland to develop a bespoke injection molded packaging solution that could withstand the rigors of varying temperatures during transit. The collaboration yielded a package design that effectively insulated the products, significantly reducing spoilage and waste. This innovation not only bolstered the company’s brand reputation for quality but also led to a substantial reduction in operational costs due to fewer product recalls and less frequent replacements. These examples underscore the tangible benefits of injection molded packaging in maintaining the integrity of temperature-sensitive goods, showcasing Holland’s expertise as a pivotal player in this specialized field.