Pavement milling and grinding plays a crucial role in Toledo, Ohio's infrastructure maintenance, particularly for utility trenching. This process involves carefully removing the road surface to prepare for subsurface utility work, using advanced machinery that can adjust to various depths for precision excavation. The method promotes environmental sustainability by recycling milled asphalt back into new pavement, reducing waste and cutting costs. In Toledo, this approach is enhanced with eco-friendly practices, including the use of recycled materials in asphalt mixes and dust suppression systems to protect air quality. The precision and efficiency of these operations ensure minimal disruption to underlying structures and contribute to a sustainable urban infrastructure network. The integration of modern technology, such as laser guidance systems, has transformed Toledo's pavement milling and grinding into an exemplar of green infrastructure practices.

When utility trenching operations are on the agenda, pavement milling and grinding play a pivotal role. This article delves into the intricacies of pavement milling and grinding, highlighting its significance in modern infrastructure projects. From Toledo, Ohio, to broader applications, we explore the process’s benefits, technological advancements, and best practices, all while considering environmental impacts. Join us as we examine how this technique not only facilitates efficient trench excavation but also contributes to the sustainability of urban landscapes.

- Pavement Milling and Grinding Overview: Understanding the Process

- The Role of Pavement Milling and Grinding in Utility Trenching

- Pavement Milling and Grinding to Toledo Ohio: Local Infrastructure Challenges

- Technological Advancements in Pavement Milling Machines for Efficient Trenching

- Best Practices for Pavement Milling and Grinding in Utility Trench Projects

- Environmental Considerations and Sustainable Practices in Pavement Milling Operations

Pavement Milling and Grinding Overview: Understanding the Process

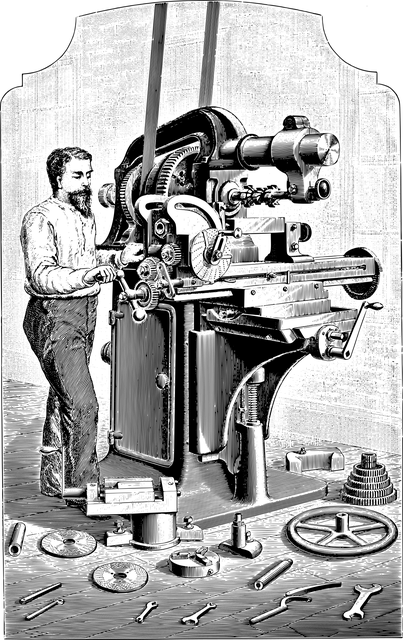

Pavement milling and grinding serve as critical processes in the maintenance and upkeep of roadways, particularly when preparing for utility trenching. This technique involves the removal of the surface layer of asphalt to accommodate subsurface utility installations or repairs. The process begins with setting up advanced machinery equipped with rotating drums or wheels that grind away at the pavement’s surface. These machines are precise and can be adjusted to mill to various depths, ensuring that only the necessary amount of material is removed. In Toledo, Ohio, for instance, this method is integral to the city’s infrastructure projects, facilitating the safe excavation of trenches for utilities like water, sewer, gas, electrical, and telecommunication lines. The milled material is then collected and recycled, emphasizing the environmental and cost-efficiency benefits of pavement milling and grinding. This not only minimizes waste but also reduces the need for new asphalt, making it an eco-friendly solution for infrastructure development and repair. The process is meticulously carried out by skilled operators who ensure that the depth, width, and grade of the cut are precise, allowing for efficient utility trenching while maintaining the integrity of the roadway structure. This precision is crucial for the longevity of the pavement and the safety of both workers and motorists. The recycled asphalt can also be used in future paving projects, creating a sustainable cycle of road maintenance.

The Role of Pavement Milling and Grinding in Utility Trenching

Pavement milling and grinding play a pivotal role in the utility trenching process, particularly when infrastructure maintenance or upgrades are required. This process involves removing the surface course of asphalt from roadways to create space for underground utilities without causing extensive damage to the existing pavement structure. In Toledo, Ohio, this method has proven effective for various projects, allowing for efficient trenching with minimal disruption to traffic flow and local businesses. The precision of modern milling machines ensures that only the necessary material is removed, which not only conserves materials but also reduces the environmental impact associated with larger-scale repairs. Once the trench is created by the milling operation, utility contractors can safely install or repair water, sewer, gas, electrical, or telecommunication lines within this excavation. After the installation or repair is complete, the removed asphalt can be repurposed, often used to restore the road surface to its original condition. This recycling aspect of pavement milling and grinding not only facilitates the trenching process for utilities but also supports sustainable construction practices in Toledo, Ohio, contributing to the longevity and safety of the city’s infrastructure network.

Pavement Milling and Grinding to Toledo Ohio: Local Infrastructure Challenges

Pavement milling and grinding serve as critical operations in maintaining and upgrading local infrastructure, particularly within Toledo, Ohio. These processes involve removing layers of pavement to various depths by controlling the diameter of the grinding teeth. In Toledo, these operations are essential for utility trenching, as they prepare the ground for new installations or repairs, ensuring a smooth and stable surface for the trenches that will follow. The city’s infrastructure faces unique challenges due to its historical layout, traffic volume, and environmental factors. Pavement milling and grinding in Toledo are not just about removing damaged asphalt but also about adapting to the specific needs of the local geography and the urban landscape, which can vary significantly across different areas within the city.

The use of pavement milling and grinding equipment is a testament to the city’s commitment to infrastructure maintenance. The process allows for precise removal of surface layers, accommodating the varying depth requirements necessary for utility trenching without compromising the integrity of the underlying layers. In Toledo, these operations are carefully planned and executed by skilled professionals who navigate the complexities of the city’s roads and underground utilities. The millings produced from the process are often recycled into new pavement materials, further emphasizing the sustainable approach to infrastructure upkeep in Toledo, Ohio. This not only facilitates efficient utility trenching but also contributes to cost savings and environmental responsibility.

Technological Advancements in Pavement Milling Machines for Efficient Trenching

Pavement milling and grinding have seen significant advancements in recent years, which have greatly enhanced the efficiency and precision of utility trenching operations. Modern pavement milling machines have incorporated sophisticated technology that allows for more accurate cuts and the ability to adapt to various pavement types and conditions. These machines are equipped with advanced cooling systems to extend their operational life and maintain optimal performance even during extended use. The integration of GPS and laser guidance systems ensures high levels of precision, which is crucial when trenching for utilities to avoid damaging existing infrastructure.

In Toledo, Ohio, these technological strides have been particularly impactful. Local contractors have leveraged the latest developments in pavement milling and grinding technology to execute projects with greater speed and less disruption to traffic and surrounding areas. The use of high-efficiency saws and cutting-edge dust collection systems minimizes debris and noise pollution, making these operations more environmentally friendly and community-friendly. As a result, the city has been able to maintain its infrastructure more effectively while also facilitating the installation and maintenance of utilities in a manner that is both timely and sustainable. These advancements underscore the importance of continuous innovation in pavement milling and grinding practices, particularly within a bustling urban environment like Toledo, Ohio.

Best Practices for Pavement Milling and Grinding in Utility Trench Projects

When executing utility trench projects that necessitate pavement milling and grinding, adherence to best practices is paramount for efficiency, safety, and the longevity of the infrastructure. Pavement milling and grinding, a process that involves cutting and removing the surface course of asphalt or concrete, must be conducted with precision to ensure minimal disruption to underlying layers and to facilitate the trenching work. In Toledo, Ohio, as in other locations, the successful completion of such projects relies on a combination of skilled operators, well-maintained equipment, and a thorough understanding of the local geological conditions and climate factors that can impact the project’s timeline and quality.

Operators performing pavement milling and grinding should be trained in the latest techniques to optimize material recovery and recycling, which not only reduces waste but also lowers costs associated with disposal and new material procurement. The use of advanced technologies, such as laser guidance systems and high-efficiency dust collection mechanisms, helps in maintaining precise cuts and reducing airborne particulates, thus complying with environmental regulations and enhancing the working environment for laborers and equipment operators. Moreover, integrating these modern technologies not only streamlines the process but also contributes to the durability of the repaired surfaces, ensuring that the roads and highways of Toledo, Ohio, remain safe and functional for commuters and residents alike.

Environmental Considerations and Sustainable Practices in Pavement Milling Operations

Pavement milling and grinding plays a critical role in maintaining infrastructure while also considering environmental impact, particularly in regions like Toledo, Ohio. The process involves removing the asphalt or concrete layer from roadways to prepare for repairs, resurfacing, or installation of utility trenches. Environmental considerations are paramount during these operations due to the potential for noise and dust pollution, as well as the emissions from machinery. Contractors engaging in pavement milling and grinding in Toledo implement sustainable practices such as utilizing eco-friendly asphalt mixes that incorporate recycled materials, reducing the ecological footprint. These advanced materials not only lessen the environmental burden but also offer superior performance characteristics. Additionally, modern equipment equipped with dust suppression systems helps minimize airborne particulate matter, thereby safeguarding local air quality. The efficient reclamation and utilization of milled material in new pavements further emphasizes a commitment to sustainability. Moreover, precise control techniques ensure minimal disruption to surrounding ecosystems, highlighting the integration of environmental stewardship with infrastructure maintenance. As a result, the pavement milling and grinding operations in Toledo exemplify how sustainable practices can be woven into essential infrastructure work, balancing urban development with ecological preservation.