CNC machining for packaging industry applications in Holland, Ohio has significantly enhanced warehouse storage efficiency by providing custom CNC-machined packaging components that offer precise and durable solutions. These advanced components not only protect products but also optimize space utilization within warehouses, leading to more efficient inventory management and operational excellence. The precision and high repeatability of these components reduce production timelines, minimize waste, and ensure rapid design modifications to meet market demands. Additionally, the integration of these components with steel racking systems creates a robust storage infrastructure that is both scalable and adaptable to changes in business needs. This synergy, combined with the benefits of CNC machining in packaging, such as improved safety, product integrity, and brand representation, positions Holland, Ohio as a leader in providing top-tier packaging solutions that contribute to a responsive and efficient supply chain. Businesses leveraging these CNC machining advantages can expect enhanced warehouse performance, optimized layouts, and the ability to maintain high standards of quality and craftsmanship in their packaging.

Optimizing warehouse storage is a cornerstone of efficient supply chain management, and the integration of steel racks with advanced CNC machining for packaging industry solutions in Holland, Ohio, stands at the forefront of this evolution. This article delves into how custom CNC-machined packaging components, a hallmark of precision engineering from Holland, Ohio, significantly enhance storage systems, thereby streamlining inventory management and reaping the key benefits of CNC machining in packaging operations. Join us as we explore the synergistic advantages these innovations bring to warehouse efficiency, setting new industry standards.

- Maximizing Warehouse Efficiency with Steel Racks and CNC Machining Solutions

- The Role of Custom CNC-Machined Packaging Components in Enhanced Storage Solutions

- Unveiling the Precision Advantage: CNC Machining for the Packaging Industry in Holland, Ohio

- Key Benefits of Implementing CNC Machining in Warehouse Packaging Operations

- Streamlining Inventory Management: The Synergy Between Steel Racks and Advanced Manufacturing Techniques

Maximizing Warehouse Efficiency with Steel Racks and CNC Machining Solutions

Steel racks are an indispensable element in optimizing warehouse storage efficiency. By providing a structured and scalable storage solution, they enable businesses to organize inventory more effectively, ensuring easier access and retrieval of products. In the realm of warehousing, the arrangement and organization of goods directly impact operational productivity. Custom cnc-machined packaging components from reputable providers like Holland, Ohio, are integral to enhancing this efficiency. These precision-engineered parts offer a perfect fit for various storage systems, ensuring stability and durability under the demands of daily use. The benefits of CNC machining in the packaging industry are manifold: it allows for rapid production of components with complex geometries, precise dimensions, and high repeatability. This technological advancement not only streamlines the manufacturing process but also reduces lead times and associated costs, ultimately contributing to a more agile and responsive supply chain. The integration of CNC machining for packaging industry applications in Holland, Ohio, thus complements the robustness of steel racking systems, creating a synergy that significantly boosts warehouse performance and adaptability to changing market demands. With the ability to customize components for specific storage requirements, businesses can optimize their warehouse layout, leading to better inventory management and operational excellence.

The Role of Custom CNC-Machined Packaging Components in Enhanced Storage Solutions

In the realm of warehouse storage, the integration of custom CNC-machined packaging components plays a pivotal role in enhancing both the efficiency and longevity of steel racks. CNC machining for the packaging industry in regions like Holland, Ohio, has become a cornerstone for precision engineering that caters to the unique demands of storage solutions. These custom components are meticulously designed to fit specific storage needs, ensuring that each packaging element is optimized for its intended application. The benefits of CNC machining in the packaging sector are manifold; it allows for the creation of complex geometries with high repeatability and accuracy, which translates into sturdier, more durable storage options. This precision engineering not only reduces the likelihood of damage during handling but also facilitates better space utilization within the warehouse, leading to a more organized and efficient storage environment.

Furthermore, the adoption of custom CNC-machined packaging components in enhanced storage solutions offers scalability and adaptability to warehouses. As businesses evolve and their storage requirements change, these components can be easily modified or upgraded to accommodate new products or changing inventory levels. The robustness and tailored nature of these components mean that they can withstand the rigors of high-density storage while maintaining the integrity of the packaged goods. This resilience not only extends the lifespan of the storage system but also minimizes downtime, ensuring that the warehouse operates at peak performance. The expertise of CNC machining for the packaging industry in Holland, Ohio, thereby becomes a strategic asset for any operation looking to optimize its storage infrastructure.

Unveiling the Precision Advantage: CNC Machining for the Packaging Industry in Holland, Ohio

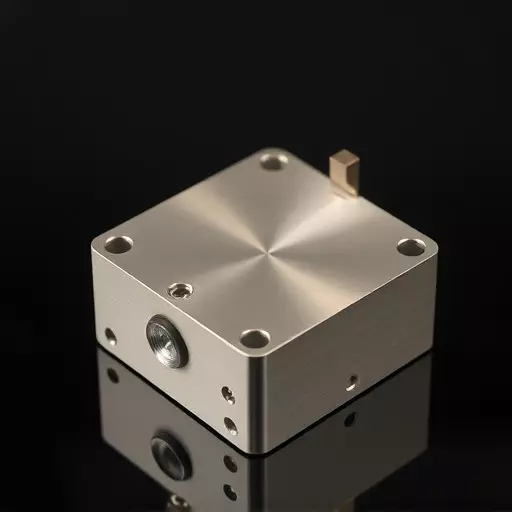

In Holland, Ohio, the packaging industry has leveraged the precision and efficiency of CNC machining to stay at the forefront of innovation. The town, much like its namesake in the Netherlands, is known for its commitment to quality and craftsmanship, which is evident in the custom CNC-machined packaging components that are manufactured here. These components, meticulously crafted by state-of-the-art computer numerical control (CNC) machines, offer unparalleled accuracy and repeatability, ensuring that every package meets stringent standards for both functionality and aesthetics. The benefits of CNC machining in the packaging industry are manifold: from reducing lead times to minimizing waste and enhancing the performance of packaging materials. The precision advantage provided by CNC machining enables packaging companies in Holland, Ohio, to produce complex parts that are essential for the protection and presentation of products, which is crucial in a competitive market. This technological advancement not only streamlines the manufacturing process but also allows for rapid prototyping and iterative design improvements, keeping companies agile and responsive to the evolving demands of their clients. The result is a robust supply chain capable of delivering high-quality packaging solutions that protect goods during transit and display them attractively on store shelves. As such, CNC machining has become an indispensable tool in the packaging industry’s arsenal, driving efficiency and innovation in Holland, Ohio.

Key Benefits of Implementing CNC Machining in Warehouse Packaging Operations

In the realm of warehouse storage solutions, the integration of CNC machining for packaging industry applications, particularly in Holland, Ohio, has been a game-changer. The benefits of incorporating custom CNC-machined packaging components into warehouse operations are manifold. Firstly, precision and accuracy are paramount in the packaging industry, where each component must fit together flawlessly to protect products during transit. CNC machining offers unparalleled precision, ensuring that every packaging element from lids to containers conforms to exact specifications, thereby enhancing product safety and shelf-life. This level of accuracy not only reduces the likelihood of damage during shipping but also streamlines the packaging process, leading to increased efficiency and reduced waste.

Moreover, the adaptability of CNC machining allows for quick modifications to packaging designs without significant downtime. As consumer demands evolve or new products enter the market, warehouses can swiftly adjust their packaging components to meet these changes. This agility in design and production can be a critical factor in maintaining a competitive edge in the marketplace. Additionally, the consistency of CNC machining results in a uniformity of product packaging that is crucial for brand recognition and customer satisfaction. The custom nature of these components means that each package can be uniquely tailored to represent the brand effectively while providing the necessary protection for the goods within. By adopting CNC machining for packaging industry needs, operations in Holland, Ohio, can significantly enhance their production capabilities and deliver high-quality, consistent packaging solutions that meet the rigorous demands of warehouse storage and distribution.

Streamlining Inventory Management: The Synergy Between Steel Racks and Advanced Manufacturing Techniques

In modern warehousing operations, the integration of steel racks with advanced manufacturing techniques, such as CNC machining for the packaging industry in Holland, Ohio, plays a pivotal role in streamlining inventory management. These state-of-the-art manufacturing processes enable the production of custom CNC-machined packaging components that are both precise and durable, ensuring that products are packaged efficiently and safely. The benefits of CNC machining in the packaging sector are manifold; it offers precision cutting, high repeatability, and reduced lead times, all of which contribute to a more agile supply chain. Steel racks, designed to accommodate these bespoke components, provide an organized storage solution that maximizes warehouse space, improves inventory visibility, and enhances overall operational efficiency. The synergy between the robust storage systems and cutting-edge CNC machining not only optimizes the packaging process but also facilitates faster retrieval and restocking of items, which is crucial for businesses aiming to maintain a competitive edge in the marketplace. With the ability to customize packaging components to fit specific inventory management needs, warehouses can adapt swiftly to changing demand patterns, ensuring that products are not only stored securely but also ready to be shipped promptly upon customer order.