Process Hazard Analysis (PHA) is a critical tool for chemical manufacturing plants, led by PHA facilitation experts who utilize pha facilitation tools and hazard identification techniques to identify and mitigate risks. These specialists guide organizations through interactive workshops, data analysis, and collaborative problem-solving methods like scenario planning, fault tree analysis, and event tree analysis. By leveraging these advanced techniques, plants can enhance safety, meet regulatory standards, and foster a culture of continuous improvement in their operations.

“In the dynamic landscape of chemical manufacturing, Process Hazard Analysis (PHA) stands as a robust framework for identifying and mitigating risks. This comprehensive guide delves into the intricacies of PHA specifically tailored for chemical plants. We explore the pivotal role played by PHA facilitation experts in enhancing risk assessment processes.

Through an analysis of effective hazard identification techniques utilizing specialized PHA tools, this article illuminates best practices for seamless integration within the chemical industry. Discover how these methodologies foster a culture of safety and efficiency.”

- Understanding PHA for Chemical Plants: A Comprehensive Guide

- The Role of PHA Facilitation Experts in Risk Assessment

- Unlocking Effective Hazard Identification Techniques with PHA Tools

- Best Practices for Implementing PHA in the Chemical Industry

Understanding PHA for Chemical Plants: A Comprehensive Guide

In the realm of chemical manufacturing, Process Hazard Analysis (PHA) serves as a robust framework for identifying and mitigating risks associated with complex industrial processes. Facilitated by PHA facilitation experts and backed by specialized tools, this comprehensive guide enables plants to navigate through intricate hazard identification techniques. By meticulously examining process scenarios, potential hazards are revealed, allowing plants to implement effective risk reduction strategies.

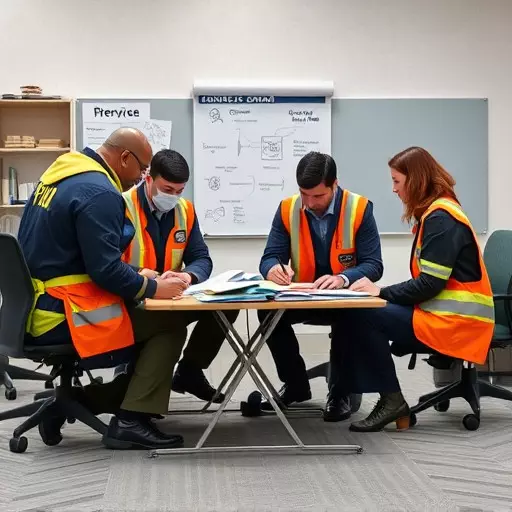

PHA facilitates a structured approach, ensuring that every facet of the chemical plant is scrutinized. Through interactive workshops and data-driven analyses, PHA facilitation tools help in uncovering hidden risks and vulnerabilities. This proactive methodology not only enhances safety but also aids in compliance with regulatory standards, ultimately fostering a culture of continuous improvement within these vital industrial hubs.

The Role of PHA Facilitation Experts in Risk Assessment

The Role of PHA Facilitation Experts in Risk Assessment

PHA facilitation experts play a pivotal role in navigating the complex landscape of chemical plant risk assessment. Armed with specialized knowledge and experience, they act as guides, ensuring that organizations employ effective pha facilitation tools and hazard identification techniques. These experts streamline the process, making it more efficient and comprehensive. They help in systematizing the gathering and analysis of data, enabling a thorough understanding of potential risks and their interconnectedness within the plant’s operations.

By leveraging advanced pha facilitation methods, these professionals facilitate collaborative discussions among diverse stakeholders. This inclusive approach fosters the identification of both obvious and subtle hazards, ensuring no stone is left unturned in the risk assessment process. Their expertise ensures that the assessment aligns with industry best practices, regulatory standards, and the unique needs of each chemical plant. Ultimately, their involvement contributes to developing robust safety protocols, minimizing risks, and fostering a culture of proactive safety management.

Unlocking Effective Hazard Identification Techniques with PHA Tools

In the realm of chemical plant safety, identifying potential hazards is a complex yet critical task. This is where Process Hazard Analysis (PHA) tools and facilitation experts play a pivotal role. These professionals are equipped with advanced methods to uncover even the subtlest risks that could pose significant threats. By employing specialized PHA facilitation tools, they navigate through intricate processes, engaging stakeholders and gathering diverse perspectives to ensure a comprehensive assessment.

The expertise lies in applying these tools to facilitate discussions and decision-making. Through structured frameworks, they guide teams through scenario planning, fault tree analysis, and event tree analysis—unleashing the power of collaborative problem-solving. This approach not only enhances hazard identification techniques but also fosters a culture of safety awareness, empowering plant operators to proactively manage risks in their chemical processes.

Best Practices for Implementing PHA in the Chemical Industry

Implementing Process Hazard Analysis (PHA) in the chemical industry is a strategic move towards enhancing safety and risk management. PHA facilitation experts recommend a structured approach, beginning with proper training to ensure all stakeholders understand the process. This involves utilizing robust hazard identification techniques, such as fault tree analysis and event tree analysis, to uncover potential hazards and their root causes.

For effective PHA facilitation, experts suggest employing specialized tools tailored for the chemical sector. These tools streamline the data collection and risk assessment processes, enabling a more comprehensive evaluation of complex processes. By integrating these best practices, chemical plants can identify vulnerabilities, implement robust safety measures, and foster a culture of continuous improvement in their operational safety protocols.