CNC-cut foam inserts are revolutionizing shipping practices in Holland, Ohio's automotive industry. These custom automotive foam inserts offer unparalleled protection for fragile components like glass, mirrors, and electronic modules by conforming to their unique shapes. Advanced CNC technology ensures precise cutting, reducing damage during transit and safeguarding high-value parts. Local businesses can use these tailored foam solutions to ensure the safety of delicate car parts, reduce returns due to damage, and enhance customer satisfaction while supporting a strong local economy.

“Revolutionize your automotive shipping with CNC-cut foam inserts—a game-changer in precision packaging. These custom automotive foam solutions are designed to cradle and protect fragile parts during transit, ensuring their integrity and reducing damage. This article explores the benefits of such advanced inserts, delving into their role in the automotive industry. From understanding the technology behind them to navigating the design process, we also highlight why choosing a local provider like Holland, Ohio businesses is advantageous for your packaging needs.”

- Understanding CNC-Cut Foam Inserts: Their Role in Automotive Shipping

- Benefits of Custom Automotive Foam Inserts for Fragile Parts

- The Process: Designing and Manufacturing Foam Inserts for Precision

- Why Choose a Local Provider: Advantages of Holland, Ohio Businesses for Your Automotive Packaging Needs

Understanding CNC-Cut Foam Inserts: Their Role in Automotive Shipping

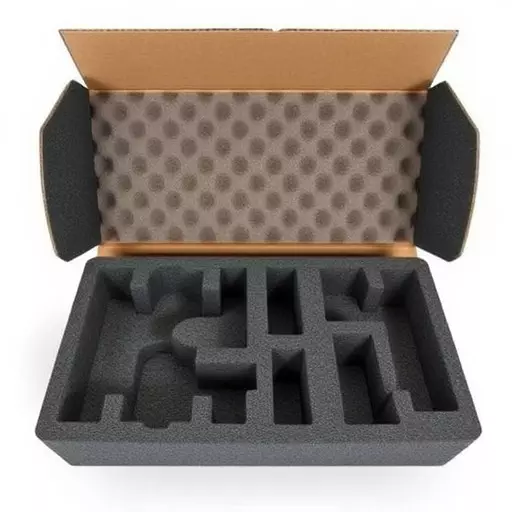

CNC-cut foam inserts play a vital role in the automotive industry, particularly when it comes to shipping and protecting fragile automotive components. These custom automotive foam inserts are meticulously designed using Computer Numerical Control (CNC) machines, ensuring precision and accuracy in every cut. By utilizing advanced CNC technology, manufacturers can create intricate foam shapes tailored to specific automotive parts, offering unparalleled protection during transportation.

In Holland, Ohio, and beyond, these innovative foam inserts have revolutionized shipping practices for various automotive industries. They are designed to accommodate unique dimensions and shapes, securely enclosing and cushioning delicate parts like glass, mirrors, and sensitive electronic modules. With their ability to conform to irregular forms, CNC-cut foam inserts provide an effective solution for safe packaging, reducing the risk of damage during transit, and ensuring the integrity of high-value automotive components.

Benefits of Custom Automotive Foam Inserts for Fragile Parts

Custom automotive foam inserts offer significant advantages when it comes to protecting fragile parts during shipping and handling. These precision-cut foam solutions are tailored to fit specific automotive components, ensuring a snug and secure hold. This customization is particularly beneficial for delicate parts that require specialized protection, such as those found in Holland, Ohio’s shipping industry. By using custom automotive foam inserts, companies can prevent damage caused by shifting during transit, significantly reducing the risk of broken or cracked parts.

The precision cutting of these foam inserts allows for a precise fit around intricate shapes and tight spaces, providing a robust barrier against shock and vibration. This level of customization ensures that fragile automotive parts receive the specialized care they need, whether they are being shipped across town or across countries. With custom automotive foam inserts, businesses in Holland, Ohio, can enhance the safety and integrity of their shipments, leading to happier customers and a reduced risk of costly returns due to damage.

The Process: Designing and Manufacturing Foam Inserts for Precision

The process of designing and manufacturing CNC-cut foam inserts for precision involves a meticulous approach to ensure optimal protection for automotive components, particularly during shipping. It begins with understanding the client’s specific requirements, including dimensions, material properties, and intended application, such as protecting fragile automotive parts in the demanding conditions of Holland, Ohio.

Using advanced CAD software, our team creates custom designs tailored to the unique shape and size of the automotive foam inserts needed. This digital stage allows for precise engineering, ensuring a perfect fit every time. Once approved, these designs are then translated into machine language, ready for CNC cutting. The precision of this technology guarantees that even the most intricate details are accurately replicated in the final product, making them ideal for safeguarding delicate automotive parts during transit.

Why Choose a Local Provider: Advantages of Holland, Ohio Businesses for Your Automotive Packaging Needs

When it comes to choosing a provider for your automotive packaging needs, opting for a local business like those in Holland, Ohio, offers numerous advantages. One of the key benefits is the ability to source custom automotive foam inserts tailored precisely to your requirements. These local providers understand the unique challenges of packaging fragile automotive parts, ensuring they employ advanced CNC cutting techniques to create precise foam inserts that protect your valuable components during shipping.

Additionally, supporting local businesses contributes to a robust and sustainable economic environment in Holland, Ohio. They often have deep roots in the community, providing employment opportunities and actively participating in local initiatives. This local focus ensures a reliable supply chain, faster turnaround times, and potentially lower shipping costs, making them an attractive choice for businesses seeking efficient and effective automotive foam inserts for shipping.