In today's competitive market, businesses in Holland, Ohio, are adopting innovative storage solutions like multi-use steel racks crafted with CNC machining technology. This advancement allows for custom, precise manufacturing of packaging components, addressing specific product and shipping needs. The benefits include unparalleled precision, efficient space utilization, durable solutions, streamlined production, consistent quality, reduced waste, improved product protection, and enhanced operational agility, all crucial for staying competitive in a fast-paced business landscape.

In today’s dynamic shipping and storage landscape, the demand for versatile, multi-use steel racks is on the rise. Traditional challenges like space constraints and inefficient loading/unloading processes have spurred a shift towards innovative solutions. This article explores the benefits of multi-use steel racks, including how CNC machining revolutionizes custom packaging components, enhancing efficiency and cost reduction. We delve into successful implementations, showcasing real-world applications in Holland, Ohio, and highlighting testimonials from industry leaders who leverage these game-changing storage systems.

- The Rise of Multi-Use Steel Racks in Shipping and Storage

- – Exploring the demand for versatile storage solutions

- – Traditional shipping and storage challenges

- CNC Machining: A Game-Changer for Custom Packaging Components

The Rise of Multi-Use Steel Racks in Shipping and Storage

In today’s dynamic shipping and storage landscape, businesses are constantly seeking innovative solutions to optimize space, streamline operations, and reduce costs. This is where multi-use steel racks emerge as a game-changer. These versatile storage systems are no longer just for warehouses; they’ve made their way into the packaging industry, revolutionizing how products are handled and stored, especially in Holland, Ohio. With advancements in CNC machining, custom cnc-machined packaging components have become readily available, enabling precise manufacturing of steel racks tailored to specific needs.

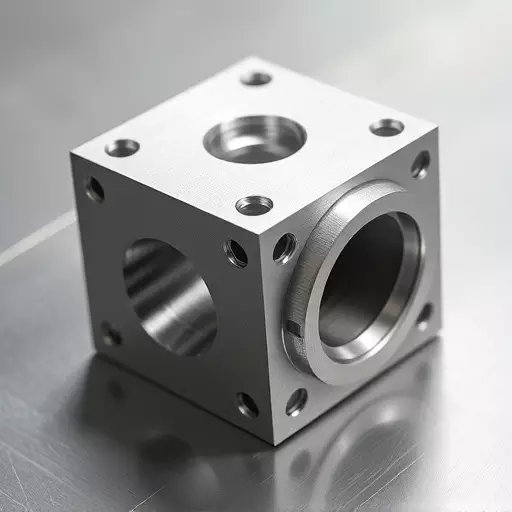

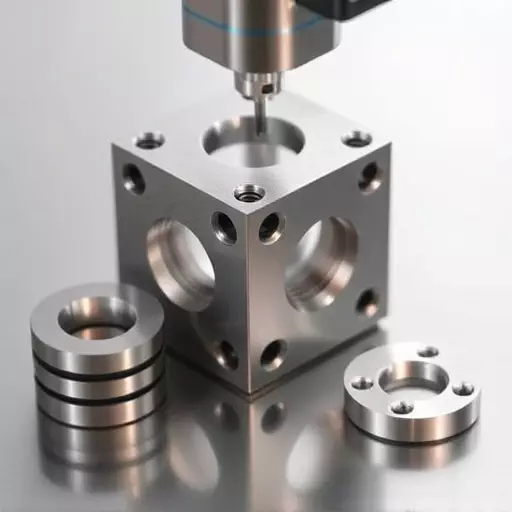

The benefits of integrating CNC machining for packaging industry applications in Holland, OH, are numerous. Custom cnc-machined packaging components offer unparalleled precision and consistency, ensuring racks meet exacting standards. This level of customization allows for efficient use of space, as these racks can be designed to fit unique product dimensions and shipping requirements. Moreover, the durability and longevity of steel make these racks a sustainable choice, providing long-term solutions for shipping and storage challenges.

– Exploring the demand for versatile storage solutions

In today’s dynamic business landscape, companies across various industries are constantly seeking innovative ways to optimize their shipping and storage processes. This drive for efficiency has sparked a growing demand for versatile storage solutions that can adapt to the ever-changing needs of modern supply chains. Multi-use steel racks, crafted with precision CNC machining techniques, have emerged as a game-changer in the packaging industry, especially in Holland, Ohio. These custom cnc-machined packaging components offer unparalleled flexibility and functionality, catering to diverse applications within the shipping and storage realm.

The benefits of incorporating CNC machining into packaging design are numerous. It enables the creation of complex, tailored solutions that perfectly accommodate unique product dimensions and handling requirements. Moreover, CNC machining streamlines production, ensuring consistent quality and precision, which is vital for maintaining efficient inventory management practices. By leveraging these advanced manufacturing capabilities, businesses in Holland, Ohio, and beyond can enhance their operational agility and remain competitive in a fast-paced market, where the ability to adapt quickly is key to success.

– Traditional shipping and storage challenges

In the dynamic landscape of shipping and storage, businesses face perpetual challenges that demand innovative solutions. Traditional methods often struggle to keep pace with the ever-evolving demands of modern supply chains, leading to inefficiencies and increased costs. From bulky, standardized containers to complex product variations, navigating these complexities requires a versatile approach. This is where custom CNC-machined packaging components step in as game-changers.

By leveraging CNC machining for packaging industry Holland Ohio, businesses can create tailored solutions that address specific product needs. These custom components offer numerous benefits, including reduced waste, improved product protection during transit, and streamlined assembly lines. The precision engineering made possible by CNC technology ensures that every package is optimized for both shipping efficiency and product integrity, ultimately enhancing customer satisfaction and contributing to a more robust overall packaging strategy.

CNC Machining: A Game-Changer for Custom Packaging Components

CNC machining has emerged as a game-changer for the packaging industry, transforming the way custom packaging components are created. Located in Holland, Ohio, many businesses are leveraging this advanced technology to manufacture precise and intricate parts that were previously impossible or cost-prohibitive to produce. By employing CNC (Computer Numerical Control) machines, manufacturers can achieve unparalleled accuracy and efficiency in creating custom steel racks, containers, and other packaging elements.

The benefits of CNC machining in the packaging sector are vast. It allows for complex designs to be swiftly translated into physical components, reducing production time and costs significantly. Moreover, CNC-machined parts offer superior consistency and quality, ensuring every piece meets precise specifications. This level of customization enables businesses to tailor their packaging solutions to specific product requirements, enhancing protection during shipping and storage while also contributing to a more sustainable and efficient logistics process.