Steel packaging solutions, particularly customizable and eco-friendly options, have become essential in the automotive industry for their exceptional strength and environmental benefits. Custom steel packaging ensures secure transport and precise fit for parts, enhancing supply chain efficiency. Sustainable steel packaging is 100% recyclable, reducing waste and carbon emissions compared to traditional materials. Its tailored designs optimize space, minimize waste, and align with the industry's sustainability goals. Global adoption by automakers demonstrates its effectiveness in protecting products while reducing environmental impact. Future trends focus on advanced steel technologies for improved performance and enhanced custom packaging solutions through cutting-edge design software.

“The automotive industry is witnessing a significant shift towards sustainable and tailored packaging solutions, with steel at the forefront. This article explores the transformative power of steel packaging for automotive parts, highlighting its environmental benefits as a viable alternative to traditional materials. We delve into the advantages of customizable steel packaging, its role in enhancing product protection, and its growing importance in the auto sector’s green revolution. From case studies to future trends, this comprehensive guide uncovers why steel is the go-to choice for efficient, safe, and eco-conscious automotive part packaging.”

- Understanding Steel Packaging Solutions for Automotive Parts

- Benefits of Sustainable Steel Packaging in the Auto Industry

- Customization: Creating Tailored Steel Packaging for Specific Parts

- The Role of Steel in Enhancing Product Protection and Safety

- Environmental Considerations: Why Steel is a Greener Choice

- Case Studies: Successful Implementation of Steel Packaging in Automotive Manufacturing

- Future Trends in Steel Packaging Design and Innovation

Understanding Steel Packaging Solutions for Automotive Parts

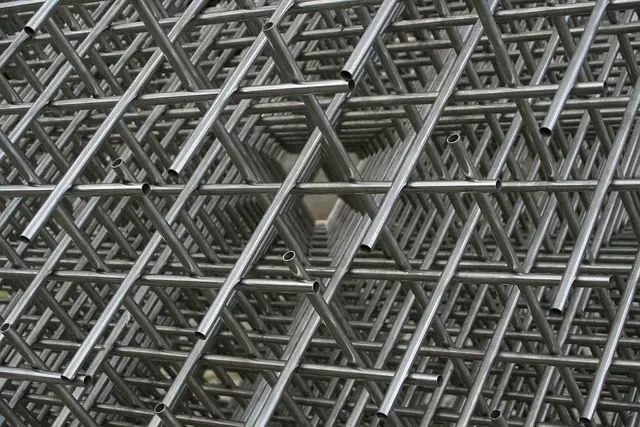

Steel packaging solutions have emerged as a pivotal aspect of automotive industry logistics, offering unparalleled strength and durability for protecting sensitive parts during transit and storage. These solutions are not just about robust protection; they also contribute significantly to sustainability. Sustainable steel packaging is designed to be recycled, reducing environmental impact and resource depletion. Furthermore, custom steel packaging caters to specific part dimensions and handling requirements, ensuring optimal fit and secure transport.

This tailored approach enhances overall efficiency in the supply chain. By leveraging advanced manufacturing techniques, steel packaging can be meticulously crafted to meet precise specifications, while also withstanding extreme conditions. This duality of strength and adaptability makes custom steel packaging a preferred choice for automotive manufacturers looking to balance cost-effectiveness with high-performance part protection.

Benefits of Sustainable Steel Packaging in the Auto Industry

Steel packaging solutions have emerged as a game-changer in the automotive industry, offering both durability and environmental sustainability. Unlike traditional materials that contribute to waste, sustainable steel packaging is recyclable and can be reused multiple times, significantly reducing the carbon footprint associated with manufacturing and transportation. This eco-friendly approach aligns with the growing demand for green practices within the sector.

Custom steel packaging plays a pivotal role in enhancing product protection during transit. Its robust nature safeguards automotive parts from potential damage, ensuring they reach their destinations without compromise. Furthermore, the versatility of steel packaging allows manufacturers to design innovative and tailored solutions that meet specific part requirements, thereby streamlining logistics and optimizing storage space.

Customization: Creating Tailored Steel Packaging for Specific Parts

In the automotive industry, where precision and safety are paramount, steel packaging solutions have emerged as a preferred choice for protecting sensitive parts during transportation and storage. One of the key advantages lies in its customization potential. Automotive manufacturers often require specialized containers to accommodate unique part shapes and sizes, ensuring secure fitment and preventing damage. Custom steel packaging plays a pivotal role here, offering tailored designs that go beyond standard templates.

This level of customization not only enhances protection but also contributes to sustainability. Steel is a recyclable material, making it an eco-friendly option for automotive packaging. Custom steel packaging can be designed with specific dimensions and features, reducing waste and resource consumption compared to generic solutions. This approach aligns with the industry’s growing emphasis on sustainable practices, as custom steel packaging can be efficiently reused and recycled, leaving a lighter environmental footprint.

The Role of Steel in Enhancing Product Protection and Safety

Steel plays a pivotal role in enhancing product protection and safety for automotive parts, making it an indispensable material in the manufacturing industry. Steel packaging solutions offer unparalleled strength and durability, ensuring that components are safeguarded during transit and storage. This is particularly crucial for delicate or high-value automotive parts, where even minor damage can lead to significant operational costs and potential safety risks.

Sustainable steel packaging is also gaining traction due to its environmental benefits. Unlike some alternative materials, steel is 100% recyclable without loss of quality, making it a leading choice for eco-conscious manufacturers. Moreover, custom steel packaging allows companies to design solutions tailored to specific part sizes and shapes, enhancing protection while optimizing space utilization. This not only reduces waste but also contributes to the overall sustainability agenda within the automotive sector.

Environmental Considerations: Why Steel is a Greener Choice

Steel packaging solutions for automotive parts offer a compelling environmental story. In an era where sustainability is paramount, choosing steel as a material for automotive packaging goes beyond aesthetics and functionality. The environmental benefits of sustainable steel packaging are multifaceted. Firstly, steel is a highly recyclable material, with over 90% of it being recycled worldwide. This recycling rate significantly reduces the need for virgin resources, thereby minimizing mining and extraction’s environmental impact.

Moreover, custom steel packaging designs can optimize space, leading to fewer transportation-related emissions. The durability of steel means products require less frequent replacement, cutting down on waste. In contrast to some plastic alternatives, steel doesn’t contribute to microplastic pollution, making it a preferred choice for eco-conscious manufacturers. These considerations underscore why sustainable steel packaging is not just an option but a responsible step towards a greener automotive industry.

Case Studies: Successful Implementation of Steel Packaging in Automotive Manufacturing

The successful integration of steel packaging in automotive manufacturing has been a game-changer for many industries. Case studies across the globe highlight its effectiveness and efficiency, showcasing how steel packaging solutions can revolutionize supply chains. For instance, leading automotive manufacturers have adopted sustainable steel packaging, reducing their carbon footprint while ensuring product integrity. This shift towards eco-friendly practices has been further enhanced by custom steel packaging designs tailored to specific part requirements.

These implementations not only offer robust protection for sensitive auto components but also facilitate easier logistics and reduced waste. The durability of steel ensures that parts arrive at their destinations without damage, minimizing returns and enhancing overall operational efficiency. Furthermore, the recyclability of steel makes these solutions a sustainable choice, aligning with environmental goals in the automotive sector.

Future Trends in Steel Packaging Design and Innovation

The future of steel packaging for automotive parts is poised for significant innovation and transformation, driven by a relentless pursuit of sustainability and enhanced performance. Manufacturers are increasingly exploring ways to incorporate advanced steels with improved corrosion resistance, strength-to-weight ratios, and recyclability into their packaging designs. This shift towards sustainable steel packaging not only reduces environmental impact but also offers enhanced protection for sensitive automotive components.

Custom steel packaging is another emerging trend that promises to revolutionise the industry. By leveraging cutting-edge technologies and design software, manufacturers can now produce highly specialised and tailored solutions to meet unique part requirements. These custom steel packages not only offer superior protection during transportation and storage but also contribute to streamlined assembly processes, ultimately leading to cost efficiencies and improved overall product quality in the automotive sector.