In today's dynamic automotive manufacturing landscape, efficient and secure packaging is crucial for component safety and integrity during transit. An emerging trend is integrating dividers within packages to optimize space and protect delicate parts. Sustainability has become a primary focus, leading to the adoption of eco-friendly materials and designs in automotive parts packaging solutions. Custom sustainable automotive parts packaging caters to specific needs while minimizing waste and adhering to industry standards. This shift towards sustainability appeals to environmentally conscious consumers and reduces the industry's carbon footprint. Dividers play a vital role by enhancing organization, optimizing space utilization, and reducing damage risk during transit. Customizable dividers facilitate efficient stock management, waste reduction, and cost-effective solutions for diverse automotive needs.

The way we package automotive parts is evolving, driven by both functionality and sustainability. In this article, we explore automotive parts packaging solutions that go beyond basic containers, introducing customized divider systems to revolutionize storage and organization. We delve into the shift towards sustainable automotive parts packaging using eco-friendly materials and analyze real-world applications. From optimizing space to enhancing safety, discover how custom automotive parts packaging is transforming an essential industry process.

- Understanding Automotive Parts Packaging Solutions

- The Shift Towards Sustainable Packaging in the Automotive Industry

- Benefits of Customized Divider Systems for Parts Storage

- Choosing the Right Materials for Automotive Parts Packaging

- Creative Uses of Dividers to Optimize Space and Organization

- Case Studies: Successful Implementation of Packaging with Dividers

Understanding Automotive Parts Packaging Solutions

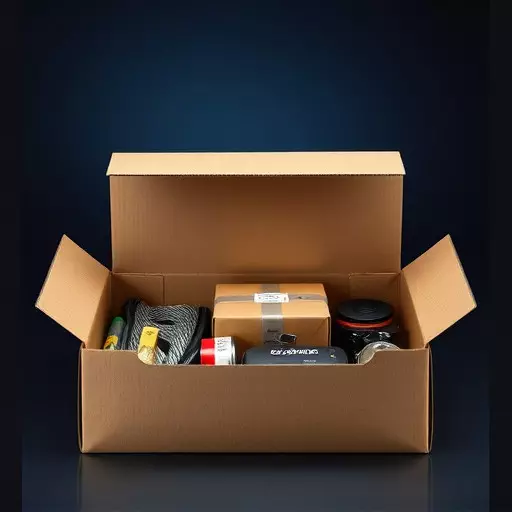

In the dynamic world of automotive manufacturing, efficient and secure automotive parts packaging solutions are paramount. These solutions play a crucial role in ensuring the safe transit of components from manufacturers to assemblers, maintaining product integrity and reducing damage during transportation. One innovative approach gaining traction is the integration of dividers within packages. Dividers not only optimize space utilization but also provide structural support, enhancing protection for delicate parts.

Beyond functionality, the sustainability of automotive parts packaging has become a significant focus. Many manufacturers are adopting eco-friendly materials and designs to minimize environmental impact. Customized sustainable automotive parts packaging solutions allow businesses to meet specific needs while reducing waste and adhering to growing industry standards for responsible production practices. This shift not only benefits the planet but also resonates with consumers who increasingly prefer environmentally conscious brands.

The Shift Towards Sustainable Packaging in the Automotive Industry

In recent years, the automotive industry has witnessed a significant shift towards sustainable practices, extending even to its packaging sector. The traditional method of using non-biodegradable materials for automotive parts packaging is increasingly being replaced by eco-friendly alternatives. This change is driven by rising consumer awareness about environmental issues and stringent regulatory norms that encourage businesses to adopt greener approaches. Sustainable automotive parts packaging solutions not only reduce the industry’s carbon footprint but also offer long-term benefits, such as cost savings and enhanced brand image.

Custom automotive parts packaging plays a crucial role in this transition. By designing specialized dividers and protective materials, manufacturers can ensure that components arrive at their destinations safely while minimizing the use of non-renewable resources. Customizable solutions allow for efficient utilization of space within packages, reducing waste and saving money. Moreover, these innovative packaging methods cater to diverse product requirements, ensuring each automotive part is protected appropriately during transit, thereby contributing to a more sustainable future for the industry.

Benefits of Customized Divider Systems for Parts Storage

Customized divider systems offer a multitude of benefits for storing automotive parts, representing an advanced step in the evolution of automotive parts packaging solutions. These systems allow for precise organization and efficient utilization of space within storage areas, whether in warehouses or on factory floors. By tailoring dividers to the exact dimensions and specifications of the parts they accommodate, these systems ensure that each component finds its designated place, streamlining retrieval processes and minimizing the risk of damage during handling.

Furthermore, customizable dividers contribute significantly to sustainable automotive parts packaging. They promote space optimization, reducing the need for excessive packaging materials and minimizing waste generation. This eco-friendly approach aligns with the growing demand for green solutions in the automotive industry, as businesses strive to meet sustainability goals while maintaining operational efficiency. Custom automotive parts packaging, thus, becomes a strategic imperative, combining functionality, cost-effectiveness, and environmental responsibility.

Choosing the Right Materials for Automotive Parts Packaging

When it comes to automotive parts packaging, selecting the appropriate materials is a critical decision. The ideal choice should not only protect the components during transportation and storage but also align with sustainable practices, given the industry’s increasing focus on environmental responsibility. One of the most popular and eco-friendly options for automotive parts packaging solutions is recycled cardboard and paper-based dividers. These materials are readily available, cost-effective, and can be custom designed to fit various part sizes, making them an excellent choice for both small and large manufacturers.

Custom automotive parts packaging allows businesses to address unique product needs while promoting sustainability. By working with specialized packaging suppliers, companies can develop innovative solutions that incorporate biodegradable or compostable materials, further reducing their environmental footprint. This approach not only meets the growing demand for sustainable automotive parts packaging but also enhances brand image and appeals to environmentally conscious consumers.

Creative Uses of Dividers to Optimize Space and Organization

In the realm of automotive parts packaging, dividers play a crucial role in enhancing organization and maximizing space utilization. Beyond their primary function of separating components, creative uses of dividers can significantly contribute to efficient custom automotive parts packaging solutions. For instance, customizable dividers allow for tailored compartmentalization, ensuring delicate or rare parts are securely nestled, while leaving no voids or extra space that could be utilized for additional components. This strategic approach not only streamlines the packing process but also reduces the risk of damage during transit, making it an ideal sustainable automotive parts packaging method.

Moreover, dividers can facilitate the creation of modular and flexible packaging systems. By employing innovative divider designs, manufacturers can accommodate various part sizes and shapes in a single container. This versatility is particularly beneficial for businesses offering a diverse range of automotive parts, as it allows for efficient stock management and reduced packaging waste. Thus, custom automotive parts packaging solutions that incorporate creative divider uses not only provide structural integrity but also offer a sustainable and cost-effective approach to meeting the unique demands of the automotive industry.

Case Studies: Successful Implementation of Packaging with Dividers

In the realm of automotive parts packaging, the implementation of dividers has proven to be a game-changer for many manufacturers. Case studies reveal that adopting custom automotive parts packaging solutions with integrated dividers offers numerous advantages. For instance, a study conducted among top auto parts suppliers showed that these specialized dividers significantly reduced damage during transit, ensuring the integrity of delicate components. By providing individual protection and separation, dividers minimize the risk of scratches, cracks, and other forms of damage, which is crucial for maintaining product quality.

Additionally, sustainable automotive parts packaging with dividers has gained traction due to its environmental benefits. Divider systems made from recyclable materials contribute to a greener approach, aligning with the industry’s growing emphasis on eco-friendly practices. Customization plays a vital role here, as manufacturers can design dividers tailored to specific part sizes and shapes, optimizing space utilization within each packaging unit. This not only reduces waste but also streamlines logistics, making it an attractive option for forward-thinking automotive businesses seeking efficient and sustainable solutions.