Steel packaging solutions, particularly customizable and sustainable designs, are transforming the construction industry. These innovative solutions offer enhanced durability, recyclability, and brand visibility for construction materials, reducing waste and environmental impact while optimizing transportation and storage efficiency. Custom steel packaging allows manufacturers to create unique, eco-friendly designs that protect products, boost brand recognition, and meet client needs, aligning with the growing demand for green building practices. Despite initial costs, the long-term benefits of reduced damage, extended product life, and improved sustainability make steel packaging a compelling choice for construction companies embracing environmentally conscious practices.

Steel packaging solutions are transforming the construction industry, offering a robust and sustainable alternative to traditional materials. This article delves into the multifaceted benefits of adopting steel packaging for construction, highlighting its environmental impact and cost savings. We explore customization options available in the market, providing unique solutions tailored to diverse construction needs. Through case studies, we demonstrate successful implementations, while also addressing challenges and charting the future trajectory of steel packaging in this dynamic sector.

- Steel Packaging Solutions for Construction Materials: A Overview

- Benefits of Sustainable Steel Packaging in Construction

- Customization Options for Steel Packaging in the Industry

- Case Studies: Successful Implementation of Steel Packaging

- Overcoming Challenges in Adopting Steel Packaging for Materials

- The Future of Steel Packaging in Construction Sector

Steel Packaging Solutions for Construction Materials: A Overview

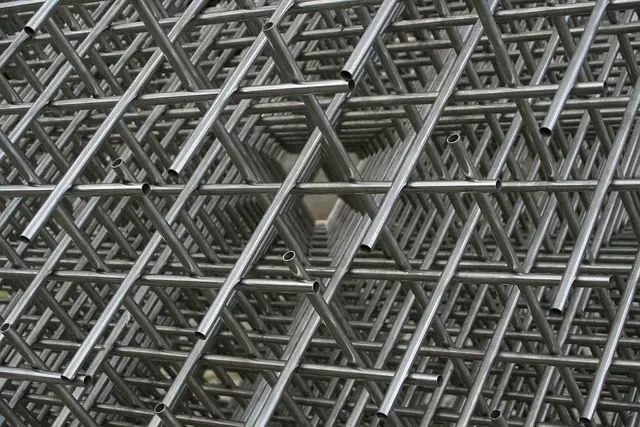

Steel packaging solutions for construction materials offer a robust and durable alternative to traditional packaging, catering to the demanding nature of the construction industry. These solutions are designed to protect and preserve the integrity of various construction products, ensuring they reach sites in prime condition. Sustainable steel packaging is increasingly favored due to its longevity, recyclability, and ability to reduce waste.

Custom steel packaging plays a pivotal role in meeting specific product requirements. Manufacturers can create tailored designs to accommodate unique shapes and sizes, offering both functional and aesthetic benefits. With a focus on sustainability, many companies are adopting innovative techniques to produce steel packaging that not only minimizes environmental impact but also enhances the overall transportation and storage efficiency of construction materials.

Benefits of Sustainable Steel Packaging in Construction

Steel packaging solutions for construction materials offer a compelling blend of durability and sustainability. Unlike traditional packaging, which often contributes to environmental waste, sustainable steel packaging is designed to be reusable and recyclable. This reduces the carbon footprint associated with production and disposal, making it an eco-friendly choice that aligns with growing industry demands for green building practices.

Custom steel packaging plays a significant role in this transition. By allowing manufacturers to design packaging tailored to specific construction material shapes and sizes, it ensures efficient protection during transit and storage. This not only minimizes damage but also optimizes space utilization, making it a practical and cost-effective option. Moreover, the longevity of steel packaging means it can be used repeatedly, further extending its environmental benefits and providing a compelling argument for adopting sustainable practices within the construction sector.

Customization Options for Steel Packaging in the Industry

In the construction materials industry, customization is key to meeting unique product requirements and brand identity needs. Steel packaging solutions offer an exceptional degree of flexibility when it comes to custom designs. Manufacturers can create tailored steel packaging that reflects specific client demands, ensuring their products stand out on the job site or retail shelf. From intricate laser-cut patterns to embossing and engraving, the possibilities are extensive.

Sustainable steel packaging is also gaining traction in this sector due to its durability and recyclability. Custom steel packaging can be designed with eco-friendly features, such as recyclable materials, minimal waste production, and longer lifespans, contributing to a more sustainable construction industry. This approach allows manufacturers to align their brand values with growing consumer demand for environmentally conscious practices.

Case Studies: Successful Implementation of Steel Packaging

The successful adoption of steel packaging in the construction industry offers compelling case studies that highlight its versatility and benefits. Many companies have pioneered the use of sustainable steel packaging solutions, particularly for bulky and heavy materials like concrete blocks and building stones. These pioneers have reported significant advantages, including reduced damage during transportation and storage, leading to lower replacement costs.

Custom steel packaging designs have also played a pivotal role in enhancing product protection and brand visibility. For example, some construction material manufacturers have customized their steel packaging to include unique logo impressions, color coding, and specialized internal dividers, ensuring that their products not only arrive safely but also stand out on store shelves. This approach has not only improved brand recognition but also contributed to the growing demand for sustainable steel packaging in the construction sector.

Overcoming Challenges in Adopting Steel Packaging for Materials

Adopting steel packaging for construction materials comes with unique challenges, but innovative solutions have made it a viable and attractive option. One significant hurdle is the perception that steel is heavy and less environmentally friendly than alternative materials. However, advancements in sustainable steel packaging have addressed these concerns, highlighting its recyclability and durability. Custom steel packaging plays a pivotal role in this transformation, allowing manufacturers to create tailored designs that balance functionality with environmental sustainability.

Another challenge lies in the cost of steel packaging compared to traditional options. Yet, long-term benefits such as increased product protection, reduced damage during transportation, and extended shelf life make a compelling case for investment. As the construction industry continues to embrace eco-friendly practices, sustainable steel packaging is poised to become a game-changer, offering both practical and environmental advantages.

The Future of Steel Packaging in Construction Sector

The construction sector is witnessing a significant shift towards eco-friendly and sustainable practices, and steel packaging solutions are at the forefront of this revolution. As awareness about environmental impact grows, traditional packaging materials are being replaced by more durable and recyclable alternatives. Sustainable steel packaging offers a compelling option due to its exceptional strength, longevity, and ability to be reused and recycled multiple times without loss of quality. This shift not only reduces waste but also minimizes the carbon footprint associated with construction material transportation.

Custom steel packaging is another area that holds immense potential. Construction companies are now able to design packaging tailored to specific product shapes and sizes, enhancing protection during transit and storage. This level of customization ensures efficiency gains and cost savings while maintaining the highest standards of safety and integrity for the materials. As the construction industry continues to evolve, embracing innovative steel packaging solutions will be key to staying competitive while contributing to a greener future.