Glass structures in Lake Orion, Michigan face corrosion challenges from harsh environments. Specialized anti-corrosion treatments using advanced nanotechnology create protective barriers, extending the lifespan of buildings and equipment while preserving aesthetics. These nanocoatings effectively repel moisture, salt, and chemicals, offering a game-changing solution for residential and industrial applications in the region's humid climate.

“Unveiling the Future of Glass Conservation: Nanotechnology’s Role in Corrosion Protection

Glass, a ubiquitous material in our modern world, faces relentless corrosion threats from environmental factors and everyday use. This article explores the innovative solution of nanotechnology in addressing this challenge. We delve into the science behind nanocoatings, their remarkable ability to provide corrosion-resistant glass treatments, and their practical applications in Lake Orion, Michigan. Discover how these advanced anti-corrosion glass protections are revolutionizing industries, ensuring longevity for transparent structures across the region.”

- Understanding Glass Corrosion: Common Causes and Effects

- The Rise of Nanotechnology in Glass Protection

- How Nanocoatings Work: A Deep Dive into the Science

- Benefits and Applications of Anti-Corrosion Glass Treatments in Lake Orion, Michigan

Understanding Glass Corrosion: Common Causes and Effects

Glass, often considered a delicate material, can suffer from corrosion, especially when exposed to certain elements and conditions. Understanding the causes and effects of glass corrosion is essential in developing effective protection methods. Common factors contributing to glass corrosion include exposure to harsh chemicals, acidic or basic solutions, and environmental conditions such as high humidity and temperature fluctuations. These factors can lead to various detrimental effects, including etching, pitting, and overall structural degradation of the glass surface.

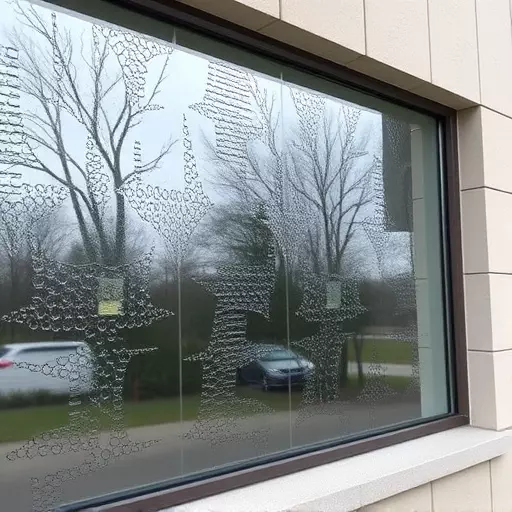

In locations like Lake Orion, Michigan, where industrial activities or aggressive environmental conditions are prevalent, glass structures may require specialized anti-corrosion treatments. Anti-corrosion coatings and glass treatments designed for such environments offer a robust solution. These advanced technologies create a protective barrier on the glass surface, preventing direct contact with corrosive substances and minimizing their detrimental impact. By employing corrosion-resistant glass coatings, buildings, windows, and other glass installations can enjoy extended lifespans, maintaining their structural integrity and aesthetic appeal.

The Rise of Nanotechnology in Glass Protection

The incorporation of nanotechnology into glass treatment and coating technologies has marked a significant shift in the realm of corrosion prevention, especially for industrial applications. Traditional methods of glass protection often rely on thick, heavy coatings that can impair the material’s clarity and aesthetic appeal. However, with the advent of anti-corrosion glass treatments and coatings enhanced by nanotechnology, a new era of advanced glass protection has emerged. These innovative solutions offer unparalleled effectiveness in combating corrosion while preserving the glass’s natural beauty and transparency.

In Lake Orion, Michigan, for instance, researchers and manufacturers are leading the way in developing cutting-edge glass anti-corrosion protection systems. By harnessing the power of nanoscale particles, these treatments create a seamless, protective layer on glass surfaces, rendering them resistant to corrosion from various environmental factors. This technology is particularly valuable in harsh industrial settings, ensuring the longevity and integrity of glass components used in equipment, windows, and structural elements. With its ability to provide corrosion-resistant glass coatings with minimal impact on the material’s properties, nanotechnology promises to revolutionize glass protection across diverse sectors.

How Nanocoatings Work: A Deep Dive into the Science

Nanocoatings have emerged as a groundbreaking solution in the realm of glass corrosion protection, offering an innovative approach to safeguarding windows and surfaces against the detrimental effects of environmental factors. These advanced coatings are engineered at the nanoscale, introducing a layer of tiny particles that create an impenetrable barrier on the glass surface. The science behind it is fascinating; by manipulating matter at such a microscopic level, manufacturers can achieve exceptional durability and protection.

The process involves applying a specialized solution containing nano-sized particles to the glass. These particles self-assemble into a uniform coating when in contact with the surface, forming a protective layer that repels moisture, salt, and other corrosive substances. This technology is particularly effective for anti-corrosion glass treatments, ensuring that structures like those in Lake Orion, Michigan, remain pristine and free from the damaging effects of corrosion. Corrosion-resistant glass coatings provide an added layer of defense, extending the lifespan of glass products and enhancing their overall performance, making them a preferred choice for various applications, including architectural and automotive designs.

Benefits and Applications of Anti-Corrosion Glass Treatments in Lake Orion, Michigan

Lake Orion, Michigan residents and businesses can greatly benefit from anti-corrosion glass treatments, a cutting-edge technology that offers superior protection against the harsh environmental conditions prevalent in the area. The region’s humid climate and exposure to salt water or deicing chemicals can accelerate metal corrosion, but not with these innovative solutions. Corrosion-resistant glass coatings have emerged as a game-changer, providing an effective barrier against moisture, chemicals, and UV rays that contribute to metal decay.

These advanced treatments are versatile in their applications, catering to various needs. For instance, they can fortify windows in historic buildings, ensuring their structural integrity without compromising aesthetic appeal. They are equally valuable for industrial settings, where equipment enclosures require robust protection against corrosive substances. By adopting anti-corrosion glass technologies, Lake Orion can preserve its architectural heritage and enhance the longevity of critical infrastructure.