Eco-friendly steel racks, crafted through CNC machining, are transforming the packaging industry in Holland, Ohio. These custom components enhance space utilization, improve product placement, and streamline logistics while reducing environmental impact compared to traditional metal fabrication methods. Adopting CNC machining for packaging in Holland positions local businesses as leaders in sustainable innovation, contributing to a greener planet. Key benefits include improved durability, structural integrity, waste reduction, precise designs, and streamlined operations, aligning with eco-conscious market demands.

In today’s eco-conscious world, the packaging industry is undergoing a green transformation. One innovative solution gaining traction is the adoption of eco-friendly steel racks, offering both sustainability and efficiency. This article explores how Custom CNC-machined packaging components, driven by advancements in cnc machining for the packaging industry in Holland, Ohio, are revolutionizing material handling. From understanding the environmental impact to examining case studies and gazing towards a sustainable future, discover the benefits of embracing cnc machining for green packaging.

- Understanding Eco-Friendly Steel Racks: A Sustainable Solution

- The Role of CNC Machining in Packaging Industry Innovations

- Customization: Unlocking Efficiency with CNC-Machined Packaging Components

- Benefits of Adopting CNC Machining for Green Packaging

- Case Study: Holland, Ohio's Approach to Eco-Conscious Material Handling

- Design and Durability: How Steel Racks Contribute to Environmental Sustainability

- The Future of Packaging: Exploring Advanced Manufacturing Techniques

Understanding Eco-Friendly Steel Racks: A Sustainable Solution

Eco-friendly steel racks are a sustainable solution that combines robust functionality with environmental consciousness. These racks, often designed with precision engineering, leverage CNC machining to create custom cnc-machined packaging components tailored to specific industry needs. In the context of the packaging industry, this technology plays a pivotal role in streamlining operations and reducing waste, making it especially prominent in Holland, Ohio’s thriving manufacturing sector.

The benefits of CNC machining in packaging are manifold. It enables the production of intricate and precise steel racks that optimize space utilization, facilitate efficient product placement, and enhance overall logistics management. By embracing eco-friendly practices, these racks minimize the environmental impact associated with traditional metal fabrication methods. This shift towards sustainability not only contributes to a greener planet but also positions businesses as industry leaders in adopting innovative, environmentally responsible solutions like CNC machining for packaging industry Holland Ohio.

The Role of CNC Machining in Packaging Industry Innovations

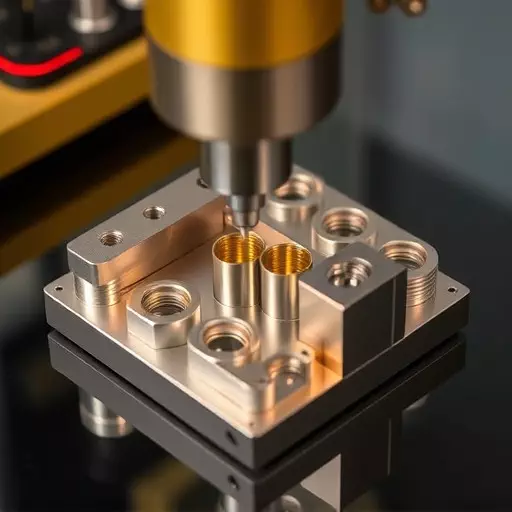

CNC machining has emerged as a game-changer for the packaging industry, revolutionizing the way custom packaging components are designed and manufactured. Based in Holland, Ohio, businesses are leveraging the precision and efficiency of CNC machining to create eco-friendly steel racks and other innovative packaging solutions. These custom cnc-machined packaging components offer numerous benefits, such as enhanced durability, improved structural integrity, and reduced waste – all while adhering to stringent environmental standards.

The integration of CNC machining into packaging production processes has facilitated the creation of intricate designs and complex geometries that were previously challenging or impossible to achieve. This technology allows for precise cutting, shaping, and forming of steel, enabling manufacturers to produce sustainable and high-quality packaging materials. As a result, businesses are able to meet the ever-evolving demands of the market, while also contributing to a greener and more responsible manufacturing landscape.

Customization: Unlocking Efficiency with CNC-Machined Packaging Components

In today’s eco-conscious world, businesses are continually seeking innovative ways to reduce their environmental impact, especially within supply chain management. Customization plays a pivotal role in enhancing efficiency, and steel racks are no exception. By leveraging advanced manufacturing techniques like CNC machining, companies can create tailored packaging components for their steel storage racks right here in Holland, Ohio. This precision engineering ensures that every rack is optimized for specific product needs, maximizing space utilization and streamlining operations.

The benefits of integrating custom CNC-machined packaging components into steel rack systems are numerous. These include improved product protection during transportation due to precise fitment, reduced material waste as designs are tailored to requirements, and faster assembly times on the factory floor. Moreover, CNC machining allows for intricate design elements that can enhance product presentation and appeal, all while adhering to eco-friendly principles by minimizing excess material use in packaging.

Benefits of Adopting CNC Machining for Green Packaging

Adopting CNC machining for green packaging offers a multitude of benefits, especially in the context of sustainability and efficiency. The packaging industry in Holland, Ohio, is witnessing a significant shift towards custom CNC-machined components, which are revolutionizing eco-friendly steel rack production. This advanced manufacturing process enables precise cutting, shaping, and forming of materials, ensuring minimal waste generation. By utilizing CNC technology, manufacturers can create intricate and tailored packaging solutions that perfectly fit various products, reducing the need for excessive material and subsequent waste.

CNC machining streamlines the production process, allowing for faster turnaround times and more consistent quality. This efficiency translates to cost savings and reduced environmental impact, making it an attractive option for eco-conscious businesses. Custom CNC-machined packaging components offer unparalleled precision and customization, catering to unique product requirements while adhering to green principles. With its ability to enhance productivity and minimize material waste, CNC machining is a key enabler in the pursuit of sustainable packaging solutions across the industry.

Case Study: Holland, Ohio's Approach to Eco-Conscious Material Handling

In Holland, Ohio, a forward-thinking approach to material handling has emerged, prioritizing both efficiency and environmental sustainability. The city’s businesses have embraced eco-conscious practices, particularly in the packaging industry, by leveraging advanced manufacturing techniques such as CNC machining. This innovative method involves custom CNC-machined packaging components, enabling precise and efficient production. By adopting these custom solutions, local manufacturers are reducing waste, minimizing material usage, and lowering their carbon footprint—all while maintaining high product quality standards.

The benefits of CNC machining in the packaging sector are multifaceted. It allows for intricate designs and complex geometries to be created with precision, ensuring optimal product protection. Moreover, this technology streamlines production processes, enhancing overall efficiency. Holland’s businesses have recognized that these custom-machined parts not only contribute to a greener environment but also foster innovation, giving them a competitive edge in the market.

Design and Durability: How Steel Racks Contribute to Environmental Sustainability

Eco-friendly steel racks are more than just functional storage solutions; their design and durability play a significant role in promoting environmental sustainability, especially within the packaging industry. These racks are meticulously crafted through advanced CNC machining processes, ensuring precision and efficiency in manufacturing. Custom CNC-machined packaging components offer numerous benefits, including reduced waste and material usage compared to traditional production methods.

By utilizing steel, a recyclable and robust material, these racks boast exceptional strength and longevity. This durability translates into fewer replacements over time, thereby minimizing the demand for raw materials and the environmental impact of manufacturing new products. Moreover, the CNC machining process allows for intricate designs and precise specifications, ensuring optimal space utilization in storage areas, which is crucial for efficient packaging operations in Holland, Ohio, and beyond.

The Future of Packaging: Exploring Advanced Manufacturing Techniques

The future of packaging is here, and it’s eco-friendly and innovative. One cutting-edge technique that’s gaining traction in the industry is CNC machining for custom packaging components. This advanced manufacturing process allows for precise creation of unique and complex shapes, sizes, and designs tailored to specific product needs. By utilizing CNC machinery, manufacturers can produce sustainable steel racks and packaging with minimal waste, reducing environmental impact.

In Holland, Ohio, and beyond, businesses are embracing the benefits of CNC machining in packaging. This technology offers enhanced precision, faster production times, and cost-effectiveness. Custom cnc-machined packaging components can be designed to protect products during transportation, ensure efficient storage, and promote brand image with innovative designs. The versatility of CNC machining makes it a game-changer for creating sustainable, high-quality packaging solutions that meet the evolving demands of today’s market.