Hybrid vehicle batteries require specialized, robust packaging due to their size, weight, and sensitivity. Industrial corrugated packaging in Holland, Ohio, offers a game-changing solution with heavy-duty, customized designs that protect against physical impacts, extreme temperatures, and moisture. This innovative approach utilizes multiple layers of corrugated cardboard, reinforced corners, rigid end caps, and secure fastening mechanisms to ensure safe battery transportation and storage, streamlining logistics and enhancing brand presentation. Key terms: industrial corrugated packaging holland ohio, heavy-duty corrugated packaging, custom corrugated packaging.

In the rapidly evolving landscape of electric mobility, hybrid vehicle batteries pose unique challenges for efficient and safe packaging. This article explores crucial aspects of hybrid battery packaging, focusing on the pivotal role of industrial corrugated packaging in ensuring safety and protection. From heavy-duty corrugated solutions to customized designs for specialized shapes, we delve into best practices, real-world case studies, and future trends shaping this vital industry, with a specific emphasis on successful implementations like those found in Holland, Ohio.

- Understanding the Unique Challenges of Hybrid Vehicle Battery Packaging

- The Role of Industrial Corrugated Packaging in Safety and Protection

- Heavy-Duty Corrugated Packaging: A Key Component for Robustness

- Customization Options for Specialized Battery Sizes and Shapes

- Best Practices for Designing Effective Battery Transport Solutions

- Case Study: Successful Implementation of Corrugated Packaging in Holland, Ohio

- Future Trends in Hybrid Vehicle Battery Packaging Innovations

Understanding the Unique Challenges of Hybrid Vehicle Battery Packaging

Hybrid vehicle batteries present distinct challenges for packaging due to their size, weight, and sensitive nature. These batteries often require specialized protection to safeguard against physical impacts, extreme temperatures, and moisture, ensuring the safety and longevity of the vehicle’s power source. Unlike conventional vehicles, hybrid electric vehicles (HEVs) demand a delicate balance between lightweight materials for fuel efficiency and robust construction to handle the demanding conditions of daily driving.

In response, manufacturers are turning to innovative solutions like custom corrugated packaging designed specifically for heavy-duty applications in Holland, Ohio, and beyond. Industrial corrugated packaging offers an ideal combination of strength, flexibility, and cost-effectiveness. By tailoring these packages to the unique dimensions and specifications of hybrid vehicle batteries, manufacturers can create a safe environment within the larger transportation container, addressing the specific challenges posed by these advanced energy storage systems.

The Role of Industrial Corrugated Packaging in Safety and Protection

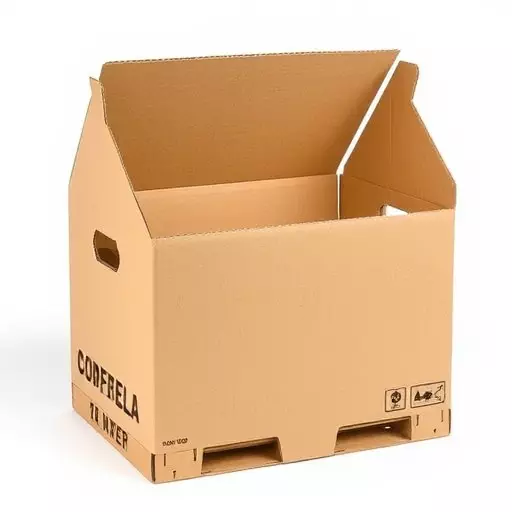

In the realm of hybrid vehicle battery packaging, safety and protection are paramount. Here’s where industrial corrugated packaging steps in as a true game-changer. The robust design of heavy-duty corrugated packaging from Holland, Ohio, offers an exceptional level of safeguarding for these delicate energy storage units. Customization is key; each package is tailored to accommodate the unique dimensions and weight of hybrid vehicle batteries, ensuring a perfect fit that minimizes movement during transportation and handling.

This specialized packaging utilizes the strength and flexibility inherent in corrugated cardboard, creating a protective barrier against impacts, drops, and environmental stressors. The layer-upon-layer structure absorbs shock and vibrations, preventing damage to the battery cells inside. Moreover, custom corrugated packaging solutions allow for integration of specific safety features like reinforced corners, rigid end caps, and secure fastening mechanisms, further bolstering the overall protection of hybrid vehicle batteries during their journey from manufacturing to installation in vehicles.

Heavy-Duty Corrugated Packaging: A Key Component for Robustness

In the realm of hybrid vehicle battery packaging, heavy-duty corrugated packaging stands out as a key component for ensuring robustness and safety. These specialized boxes are designed to withstand extreme conditions, from rough handling during transportation to exposure to various weather elements. The industrial corrugated packaging Holland, Ohio, offers is no exception—it’s meticulously crafted to protect high-value, sensitive batteries, ensuring they reach their destinations intact.

Custom corrugated packaging plays a pivotal role in catering to the unique requirements of hybrid vehicle manufacturers. By utilizing advanced design techniques and materials, these custom solutions can accommodate specific battery shapes and sizes while maximizing protection. This tailored approach not only safeguards the batteries but also streamlines logistics, making it an indispensable aspect of modern automotive supply chains.

Customization Options for Specialized Battery Sizes and Shapes

Hybrid vehicle batteries come in a variety of sizes and shapes, each requiring a tailored packaging solution to ensure safety and protection during transportation and storage. Customization options for these specialized battery configurations are a key aspect of modern industrial packaging design. Companies like those based in Holland, Ohio, specializing in heavy-duty corrugated packaging, offer extensive customization capabilities.

By leveraging custom corrugated packaging, manufacturers can accommodate unique battery dimensions while incorporating enhanced protective features such as shock absorption, secure fastening mechanisms, and specialized dividers to prevent movement during transit. This level of customization not only ensures the safe arrival of these valuable assets but also provides an opportunity to create a visually appealing and brand-aligned package that enhances the overall unboxing experience for both businesses and end-users alike.

Best Practices for Designing Effective Battery Transport Solutions

When designing transport solutions for hybrid vehicle batteries, safety and protection against damage are paramount. Heavy-duty corrugated packaging in Holland, Ohio, is a smart choice due to its superior strength and impact resistance. Custom corrugated packaging allows for precise battery fit, minimizing movement during transit and reducing the risk of internal short circuits or physical harm.

Additionally, employing best practices like using high-quality materials, adding internal bracing, and incorporating robust sealing mechanisms further ensures the integrity of the packaging. These measures not only safeguard batteries from external shocks but also control temperature fluctuations, a critical factor in maintaining battery health during transportation.

Case Study: Successful Implementation of Corrugated Packaging in Holland, Ohio

In Holland, Ohio, a leading automotive manufacturer faced a unique challenge: safely and efficiently packaging hybrid vehicle batteries for both domestic and international shipping. The solution? Custom heavy-duty corrugated packaging designed to protect these delicate, high-value components during transit. This implementation showcased the power of industrial corrugated packaging in mitigating damage and ensuring product integrity.

The custom corrugated packaging solution not only withstood the rigors of global transportation but also integrated specialized features for added protection. By leveraging advanced printing techniques, the manufacturer included clear panels allowing for easy battery inspection without opening the package. This transparency streamlined quality control processes while minimizing the risk of handling damage. The success in Holland, Ohio, serves as a shining example for other industries seeking innovative and robust packaging solutions for their sensitive products.

Future Trends in Hybrid Vehicle Battery Packaging Innovations

The future of hybrid vehicle battery packaging is poised for significant advancements driven by evolving technologies and growing environmental concerns. Manufacturers are increasingly exploring innovative materials and designs to meet the demanding requirements of electric vehicles (EVs) while ensuring safety, durability, and lightweight construction. One notable trend is the increased adoption of heavy-duty corrugated packaging, particularly in North America, such as the industrial corrugated packaging solutions available in Holland, Ohio. These advanced packaging types offer enhanced protection for delicate battery components, making them ideal for high-performance hybrid systems.

Customized corrugated packaging is another area gaining traction. With the rise of diverse EV models and battery configurations, manufacturers are customizing their packaging to fit specific battery dimensions and weight requirements. This approach not only ensures optimal protection but also streamlines production processes, reducing waste and costs. The integration of smart sensors and advanced tracking technologies into these custom packages further enhances supply chain visibility, enabling efficient monitoring of battery conditions during transportation and storage.