Expanded Polypropylene (EPP) foam packaging, a lightweight and versatile material, is transforming industries in Holland, Ohio. Its unique properties—including superior strength-to-weight ratio, impact resistance, insulation, and moldability—offer significant advantages for product protection during transportation, while also reducing waste and environmental impact. EPP foam solutions are gaining popularity due to their cost savings, customizability, and sustainability, positioning them as a game-changer across diverse sectors like construction, automotive, healthcare, food & beverage, and electronics.

“Discover the revolutionizing impact of high-performance foam materials, particularly Lightweight EPP Molded Foam Packaging, in Holland, Ohio. This innovative technology is transforming industries with its exceptional benefits, offering enhanced protection and efficiency in packaging. Expanded Polypropylene (EPP) foam solutions showcase unparalleled versatility and sustainability. Explore its diverse applications across various sectors and be among the pioneers embracing this game-changing material, shaping a future filled with lighter, more efficient products.”

- What are High-Performance Foam Materials?

- Lightweight EPP Molded Foam Packaging: A Game-Changer in Holland, Ohio

- Benefits of EPP Foam Packaging: Enhanced Protection and Efficiency

- Expanded Polypropylene (EPP) Foam Solutions: Versatility and Sustainability

- Applications of High-Performance Foam in Various Industries

- The Future of Foam: Innovations and Trends in the Industry

What are High-Performance Foam Materials?

High-Performance Foam Materials, often referred to as advanced or specialized foams, represent a cutting-edge category in the packaging industry. These innovative materials are characterized by their exceptional strength-to-weight ratio, making them ideal for various applications, especially in the realm of lightweight EPP molded foam packaging. The term ‘high-performance’ is derived from their superior mechanical properties, offering enhanced durability and impact resistance compared to traditional foams.

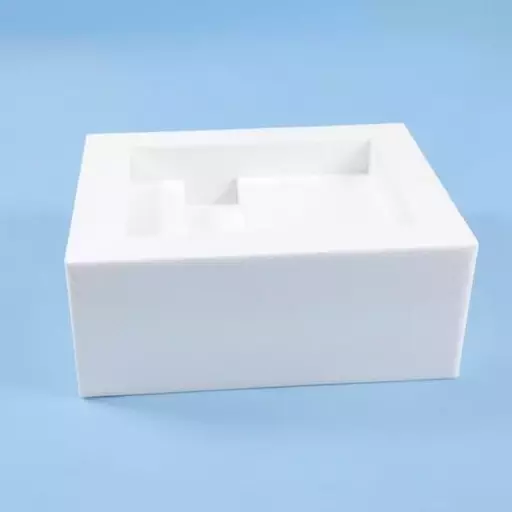

One prominent example of these materials is Expanded Polypropylene (EPP) foam, which has garnered significant attention for its versatility and benefits in the market. EPP foam solutions are not only lightweight but also provide excellent thermal insulation, making them perfect for protecting sensitive products during transportation. This advanced packaging material can be molded into various shapes, ensuring optimal product support and protection while reducing weight and material waste, making it a preferred choice for businesses in Holland, Ohio, and beyond.

Lightweight EPP Molded Foam Packaging: A Game-Changer in Holland, Ohio

In Holland, Ohio, a revolutionary shift is taking place in the realm of packaging with the advent of Lightweight EPP Molded Foam. This innovative solution, crafted from expanded polypropylene (EPP), is transforming the way local businesses approach product protection and transportation. The key lies in its remarkable attributes—lightweight yet robust, offering unparalleled shock absorption and insulation. By adopting this advanced foam material, companies are reaping numerous benefits, including reduced shipping costs, minimal environmental impact, and enhanced product safety during transit.

The impact of Lightweight EPP Molded Foam extends beyond mere cost savings. Its customizable nature allows manufacturers to create tailored packaging solutions, ensuring perfect fits for diverse products, from fragile electronics to delicate glassware. This level of precision not only minimizes damage but also adds a layer of professionalism to the overall unboxing experience, making it a game-changer in the competitive e-commerce market. With its superior performance and eco-friendly credentials, expanded polypropylene foam solutions are undoubtedly paving the way for a more sustainable future in packaging.

Benefits of EPP Foam Packaging: Enhanced Protection and Efficiency

The lightweight nature of EPP foam packaging is a game-changer for shipping and logistics in Holland, Ohio, and beyond. This innovative material offers unparalleled protection for fragile items while significantly reducing weight and transportation costs. By utilizing expanded polypropylene (EPP) foam solutions, businesses can streamline their packaging processes and enhance overall efficiency.

One of the key benefits of EPP foam is its exceptional impact resistance. The molded foam’s unique cellular structure provides a cushion-like effect, absorbing and distributing shock forces during transit. This ensures that delicate products arrive at their destination in pristine condition, minimizing damage and returns. Moreover, EPP packaging is highly versatile, customizable to fit various product shapes and sizes, making it an ideal solution for diverse industries.

Expanded Polypropylene (EPP) Foam Solutions: Versatility and Sustainability

Expanded Polypropylene (EPP) foam is a versatile material that offers numerous advantages for various applications. Known for its lightweight properties, EPP molded foam packaging in Holland, Ohio, has gained popularity due to its ability to provide superior protection while minimizing weight and volume. This makes it an ideal choice for shipping and transportation industries, where reducing freight costs and improving product handling are key objectives.

Beyond its physical attributes, EPP foam solutions contribute to sustainability. The material is fully recyclable, making it a responsible option for businesses aiming to reduce their environmental impact. Additionally, EPP’s structural integrity ensures longevity, further extending the lifespan of products and minimizing waste. These benefits make expanded polypropylene an attractive choice for companies seeking efficient, eco-conscious packaging solutions.

Applications of High-Performance Foam in Various Industries

High-performance foam materials, such as lightweight EPP molded foam packaging from Holland, Ohio, have revolutionized various industries due to their unique properties and versatile applications. Expanded polypropylene (EPP) foam is particularly valued for its exceptional strength-to-weight ratio, making it an ideal solution for packaging and protection in the transportation sector. The benefits of EPP foam packaging are numerous; it not only reduces weight and fuel consumption but also offers superior impact resistance, ensuring the safe arrival of goods.

These innovative foams find their utility in diverse fields. In construction, they contribute to energy-efficient insulation while providing lightweight yet robust solutions for building materials. The automotive industry benefits from EPP’s ability to absorb impacts, enhancing passenger safety without adding significant vehicle weight. Furthermore, expanded polypropylene foam solutions are increasingly used in healthcare for custom-molded protective gear and medical devices due to their biocompatibility and flexibility.

The Future of Foam: Innovations and Trends in the Industry

The future of foam is bright and innovative, as the industry continues to evolve with cutting-edge solutions. One prominent trend is the increased use of lightweight EPP (expanded polypropylene) molded foam packaging in Holland, Ohio, and beyond. This material offers remarkable benefits for various industries, from food and beverage to electronics and retail. Its unique properties, such as superior impact resistance, insulation capabilities, and low weight, make it an ideal choice for sustainable and cost-effective packaging solutions.

The demand for environmentally friendly options has driven the development of expanded polypropylene foam solutions. As consumers become more conscious of their ecological footprint, manufacturers are responding with innovative designs that reduce waste and minimize the environmental impact without compromising performance. These trends suggest a promising future where high-performance foam materials like EPP continue to revolutionize industries, offering enhanced protection and efficient logistics while aligning with sustainability goals.