CNC router cutting services in Holland, Ohio, have transformed material shaping with unprecedented precision and efficiency. Professionals leverage this technology to cut and carve diverse materials like wood, acrylic, metal, and foam for industries from woodworking to aerospace. By utilizing specialized CNC routers and toolpaths, they ensure consistent quality and accuracy in creating complex shapes and patterns. These services offer significant cost savings, minimize waste, and streamline manufacturing processes, making them a reliable solution for various sectors. The versatility of CNC routers allows for cutting through unique material properties, catering to specific applications like furniture crafting, signage, aerospace, automotive, and prototyping.

“Discover the transformative power of Advanced CNC Router Cutting Technology, a game-changer in modern manufacturing. This comprehensive guide explores the intricate world of CNC router cutting services, from its foundational principles to cutting-edge innovations. We delve into the benefits of professional CNC cutting for precision and efficiency, dissect different material types and their applications, and highlight how services in Holland, Ohio are revolutionizing local manufacturing processes. Prepare to be inspired by the endless possibilities.”

- Understanding CNC Router Cutting Technology: A Comprehensive Overview

- The Benefits of Professional CNC Cutting Services for Precision and Efficiency

- Different Types of CNC Router Materials and Their Applications

- How CNC Router Cutting Service in Holland, Ohio Enhances Manufacturing Processes

- Advanced Techniques in CNC Cutting: Innovation and Customization

- Case Studies: Successful Implementations of CNC Router Cutting Services

Understanding CNC Router Cutting Technology: A Comprehensive Overview

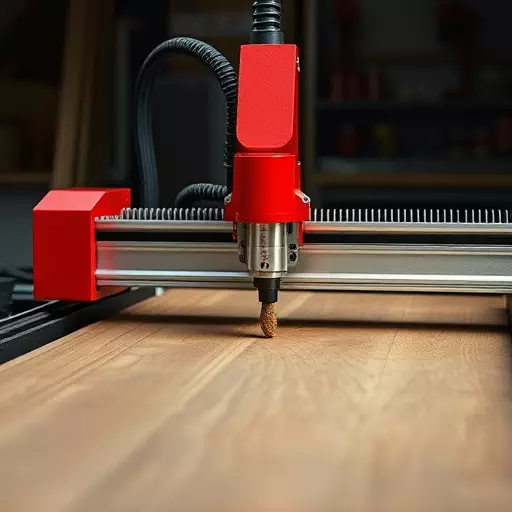

CNC router cutting technology has revolutionized the way we shape and carve various materials, offering unprecedented precision and efficiency. At its core, CNC stands for Computer Numerical Control, where a computer program guides a machine to cut or engrave specific designs with high accuracy. This advanced machining process involves moving a router bit along pre-programmed paths, allowing for intricate cuts on diverse surfaces. The result is a seamless fusion of digital design and physical creation.

In the realm of CNC router cutting service Holland Ohio, professionals utilize this technology to transform a wide array of materials, from wood and acrylic to metal and foam. Professional CNC cutting services cater to diverse industries, including woodworking, signage, automotive, and even aerospace. By employing different types of CNC routers with varying toolpaths and speeds, manufacturers can cut, engrave, or carve complex shapes and patterns on various materials, ensuring consistent quality and precision.

The Benefits of Professional CNC Cutting Services for Precision and Efficiency

Professional CNC cutting services offer a multitude of benefits for businesses and manufacturers across various industries. One of the primary advantages is the unparalleled precision they bring to the table. With advanced CNC router cutting technology, these services can handle even the most intricate and detailed designs with exceptional accuracy. This level of precision ensures that every cut is exact, leading to superior product quality and minimal waste, which directly impacts cost savings.

Moreover, employing a professional CNC cutting service provides businesses with access to specialized equipment and highly skilled operators. CNC routers are capable of cutting through diverse materials, including wood, metal, acrylic, and foam. The expertise of professionals allows them to adapt these machines to specific project requirements, ensuring efficient production times without compromising on quality. This streamlines the manufacturing process, making it an efficient and reliable solution for businesses in Holland, Ohio, and beyond.

Different Types of CNC Router Materials and Their Applications

CNC routers are versatile machines capable of cutting and carving various materials, each offering unique properties for specific applications. The types of CNC router materials include wood, acrylic, aluminum, steel, and even foam. Wood is a popular choice due to its availability and ease of use, suitable for crafting furniture, models, and decorative items. Acrylic, known for its durability and transparency, is ideal for creating signs, displays, and transparent parts.

Aluminum and steel are preferred for more demanding projects, offering excellent strength and precision. These materials find applications in aerospace, automotive, and industrial sectors for manufacturing components with tight tolerances. Foam, a lightweight alternative, is used in prototyping and model making, providing a cost-effective solution for creating intricate designs. Professional CNC cutting services, like those offered in Holland, Ohio, cater to diverse industries by utilizing these materials to deliver precise, high-quality cuts tailored to specific project needs.

How CNC Router Cutting Service in Holland, Ohio Enhances Manufacturing Processes

CNC router cutting service in Holland, Ohio, is transforming manufacturing processes across various industries. These professional CNC cutting services leverage advanced technology to offer precise and efficient material processing. From wood, plastic, aluminum, and acrylic to more exotic materials like composite plastics and foam, CNC routers can handle a wide array of projects with remarkable accuracy. This versatility makes them indispensable for custom fabrication, prototyping, and even mass production.

The service providers in Holland, Ohio, often employ state-of-the-art CNC machines equipped with high-resolution axes and powerful tools. This technology enables them to create intricate designs and complex geometries that were once challenging or impossible to achieve using traditional methods. The precision and speed of CNC router cutting services not only reduce production time but also minimize material waste, making it an eco-friendly choice for many businesses. Moreover, the ability to quickly iterate designs and adapt to changing market demands gives manufacturers a competitive edge in today’s fast-paced industrial landscape.

Advanced Techniques in CNC Cutting: Innovation and Customization

In the realm of CNC router cutting, innovation and customization are driving forces behind the advanced techniques that shape modern manufacturing. Professional CNC cutting services in Holland, Ohio, have evolved to accommodate a diverse range of materials, from wood and plastic to metal and even composite structures. This versatility allows for unparalleled creativity in design and engineering, enabling manufacturers to bring unique concepts to life with precision and speed.

The latest advancements in CNC router cutting technology offer more than just improved efficiency; they open up new possibilities for customization. By leveraging advanced software and state-of-the-art machinery, professional CNC cutting services can handle complex geometries and intricate patterns, ensuring that each project is tailored to specific requirements. Whether it’s for prototyping, small batch production, or large-scale manufacturing, these techniques empower manufacturers to deliver high-quality, one-of-a-kind products that stand out in the market.

Case Studies: Successful Implementations of CNC Router Cutting Services

In the realm of precision manufacturing, case studies illustrate the transformative power of advanced CNC router cutting technology. Businesses across various industries in Holland, Ohio, have successfully leveraged professional CNC cutting services to streamline their production processes and elevate product quality. From woodworking to plastic fabrication, these implementations showcase how CNC routers can cut complex shapes with unparalleled accuracy, speed, and efficiency.

For instance, local furniture manufacturers have utilized CNC router cutting services to produce intricate designs with minimal waste. Similarly, automotive parts suppliers have benefited from the ability to create precise, customized components using a variety of materials, including metal, acrylic, and wood. These successful integrations highlight how modern CNC router cutting technology can adapt to diverse material types, catering to specific industry needs and driving innovation in manufacturing practices.