CNC-machined molds provide innovative packaging solutions in Holland, Ohio, with custom foam inserts tailored to protect sensitive electronics. These ESD-safe anti-static foams ensure the secure transportation of electrical components, preventing damage and reducing production risks. By offering precise fits and advanced safety features, this approach enhances product security while maintaining cost-efficiency in specialized applications for local electronics manufacturing.

“Revolutionize your packaging game with CNC-machined molds, a precision manufacturing technique transforming the industry. This article offers an in-depth look at the world of custom foam inserts tailored for electronics manufacturing in Holland, Ohio. From understanding the fundamentals to exploring advanced features, we delve into how these molds enhance product protection. Discover the benefits of protective foam inserts, including ESD-safe and anti-static foams, and learn why they are indispensable for delicate electronic components.”

- Understanding CNC-Machined Molds for Packaging: A Comprehensive Overview

- Benefits and Applications of Protective Foam Inserts in Electronics Manufacturing

- Customization and Safety Features: ESD-Safe and Anti-Static Foams for Delicate Components

Understanding CNC-Machined Molds for Packaging: A Comprehensive Overview

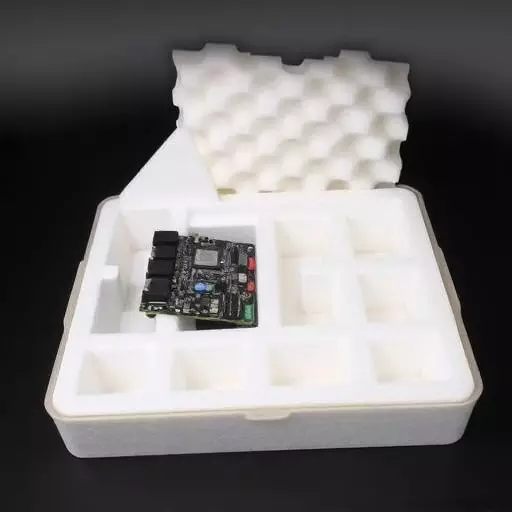

CNC-machined molds for packaging are an innovative solution in the manufacturing industry, offering precise and customized shapes to protect sensitive products. These molds are created using Computer Numerical Control (CNC) machines, which cut and shape materials with exceptional accuracy. This technology is particularly valuable for creating protective foam inserts designed for delicate items like electronics. By utilizing CNC machining, manufacturers can produce complex geometries, ensuring perfect fitment around electronic components in packaging.

When it comes to specialized applications, such as electronics in Holland, Ohio, custom foam inserts play a crucial role. ESD-safe (Electrostatic Discharge) foam inserts are commonly used to prevent damage to sensitive electrical parts during transportation. These anti-static foams are meticulously designed and cut to fit various packaging requirements, providing a safe haven for electronics. CNC machining allows for the customization of these foam inserts, ensuring they meet specific product needs while maintaining cost-effectiveness.

Benefits and Applications of Protective Foam Inserts in Electronics Manufacturing

Protective Foam Inserts play a vital role in Electronics Manufacturing, offering numerous benefits that ensure the safe transportation and storage of sensitive components. These ESD-safe (Electrostatic Discharge) foam inserts are designed to create a customized, secure fit for various electronic devices, from tiny circuit boards to large assembly units. By using custom foam inserts, manufacturers can precisely adapt packaging solutions to unique product shapes and sizes, minimizing the risk of damage during handling and shipping.

One of the key advantages of protective foam inserts is their ability to provide anti-static protection. Electronics are susceptible to electrostatic discharge, which can cause irreversible damage to delicate components. The static-dissipative properties of ESD-safe foam ensure that any built-up charge is safely conducted away from sensitive parts, protecting them from potential harm. This is especially critical in the high-tech industry where even minor electrostatic events can result in costly failures and production delays.

Customization and Safety Features: ESD-Safe and Anti-Static Foams for Delicate Components

In the realm of CNC-machined molds for packaging, customization is key, especially when dealing with delicate electronic components. Beyond precise dimensions and intricate designs, modern manufacturers offer specialized protective foam inserts tailored to specific product needs. These custom foam inserts serve a dual purpose: they not only ensure secure placement and protection during transit but also incorporate advanced safety features.

One such innovation is ESD-safe (Electrostatic Discharge) foam, designed to safeguard sensitive electronics from harmful static electricity build-up. Additionally, anti-static foam for electronics prevents the attraction and retention of particles that could damage components. These ESD-safe and anti-static foam inserts are particularly valuable in the manufacturing sector, where products like electronics assembled in Holland, Ohio, require meticulous care during packaging to avoid costly failures or returns.