“Discover the future of pipeline installation with Trenchless Technology, a revolutionary approach transforming urban infrastructure development. This article explores advanced techniques like Directional Boring and Horizontal Directional Drilling (HDD), offering precise, versatile, and environmentally friendly solutions. Learn how these methods minimize disruption, enhance efficiency, and unlock new possibilities for underground infrastructure projects. From reduced excavation to successful urban implementations, understand why Trenchless Technology is the game-changer in pipe laying.”

- Understanding Trenchless Technology: A Modern Approach to Pipeline Installation

- Directional Boring Technique: Precision and Versatility in Pipe Laying

- Horizontal Directional Drilling (HDD): Unlocking Efficient Underground Infrastructure Development

- Advantages of Using Trenches Less: Reduced Disruption and Environmental Impact

- Equipment and Tools for Trenchless Pipeline Installation

- Common Applications: When to Employ Trenchless Techniques

- Case Studies: Successful Implementation of Trenchless Technology in Urban Settings

Understanding Trenchless Technology: A Modern Approach to Pipeline Installation

In recent years, the pipeline installation sector has witnessed a significant evolution with the advent of Trenchless Technology. This modern approach is transforming traditional excavation methods and offering numerous advantages. One of its most advanced applications is Directional Boring, which allows for the precise placement of pipelines without the need for extensive trenches.

Horizontal Directional Drilling (HDD) is a key technique within Trenchless Technology, enabling pipes to be installed in a horizontal manner, even under existing structures and through challenging terrains. This method has revolutionized pipeline construction, especially in urban areas with dense infrastructure. By employing HDD, contractors can minimize disruptions, reduce excavation costs, and enhance overall project efficiency.

Directional Boring Technique: Precision and Versatility in Pipe Laying

The Directional Boring Technique is a revolutionary approach in pipeline installation, offering unprecedented precision and versatility. This innovative method, often referred to as Horizontal Directional Drilling (HDD), eliminates the need for traditional excavation methods, thus reducing environmental impact and minimizing disruptions to surfaces above ground. With trenchless technology, pipes can be laid horizontally through the earth with remarkable accuracy, making it ideal for installing utilities in urban areas where space is limited and preserving landscapes is paramount.

This technique employs specialized equipment to create a tunnel beneath the surface, guiding pipes precisely to their destination. This not only streamlines the installation process but also enhances safety by minimizing the risk associated with working at depth. The versatility of Directional Boring Toledo allows for the installation of various pipe materials and sizes, making it a preferred choice in the infrastructure development sector, where efficient and sustainable construction is paramount.

Horizontal Directional Drilling (HDD): Unlocking Efficient Underground Infrastructure Development

Horizontal Directional Drilling (HDD) has emerged as a revolutionary trenchless technology transforming underground infrastructure development. This innovative technique involves using specialized equipment to bore horizontally beneath the earth’s surface, allowing for the installation of pipes, cables, and other utilities without traditional excavation methods. By navigating through diverse geological formations with precision, HDD offers numerous advantages over conventional trenching.

In Directional Boring Toledo and similar urban areas, HDD is particularly valuable due to its ability to minimize disruption to existing structures, traffic flow, and sensitive environments. This non-invasive approach significantly reduces construction time and costs while ensuring the safety and integrity of underground utilities. As a result, Horizontal Directional Drilling is increasingly preferred by contractors, engineers, and municipalities for various infrastructure projects, including water main replacements, gas line installations, and electric utility upgrades.

Advantages of Using Trenches Less: Reduced Disruption and Environmental Impact

The traditional method of pipeline installation often involves extensive excavation and trenching, which can lead to significant disruptions in urban areas or environmentally sensitive sites. This process not only causes temporary inconvenience for communities but also poses potential risks to underground utilities and landscapes. However, with the advent of Trenchless Technology, these challenges are being addressed effectively.

Horizontal Directional Drilling (HDD) and Directional Boring techniques offer a revolutionary approach by allowing pipelines to be installed without the need for deep trenches. By guiding pipes through the soil using hydraulic pressure and precision navigation, these methods minimize surface disruption. This not only reduces construction time but also lowers the environmental impact, preserving landscapes and underground infrastructure intact. Moreover, HDD is particularly advantageous in urban settings, where space is limited and protection of existing structures is paramount.

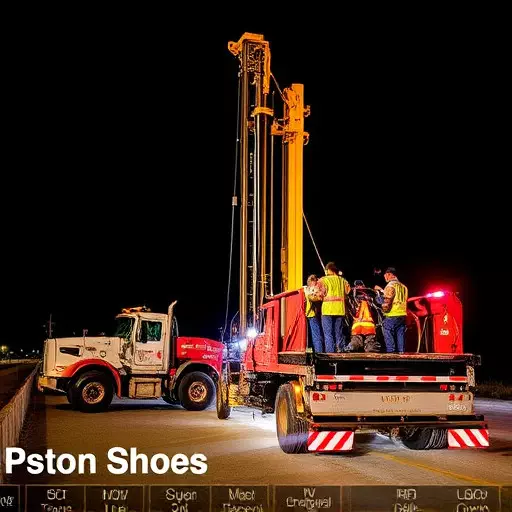

Equipment and Tools for Trenchless Pipeline Installation

In the realm of trenchless pipeline installation, advanced equipment and tools are pivotal in achieving precise and efficient underground utility placement. One of the most renowned techniques is Horizontal Directional Drilling (HDD), which employs a rotary drilling rig to create a buried tunnel for the pipe. This innovative method, often utilizing Directional Boring Toledo technology, allows for the installation of pipelines without the need for extensive excavation.

The trenchless approach offers numerous benefits, including reduced disruption to the surface, faster project completion times, and lower labor costs. Key components of the HDD process include specialized drilling machines, pipe guides, and various cutting tools. These tools enable operators to navigate through challenging terrain, ensuring the pipeline is securely positioned without damaging surrounding structures or disrupting traffic in bustling urban areas.

Common Applications: When to Employ Trenchless Techniques

In recent years, Trenchless Technology has emerged as a game-changer in pipeline installation, offering efficient and innovative solutions for various applications. When traditional excavation methods would be disruptive or impractical, Horizontal Directional Drilling (HDD) and Directional Boring Toledo techniques come into play. These advanced methodologies allow for the installation of pipelines – be it gas, water, or sewage – beneath existing structures, roads, or environmentally sensitive areas without the need for extensive trenching.

Common applications for trenchless techniques include urban renewal projects, where minimizing disruption to bustling cities is crucial; retrofitting infrastructure in densely populated areas; and installing pipelines under rivers or other bodies of water using Horizontal Directional Drilling. This technology ensures faster project completion times, reduces environmental impact, minimizes traffic congestion, and lowers the risk of damage to underground utilities.

Case Studies: Successful Implementation of Trenchless Technology in Urban Settings

The successful adoption of Trenchless Technology in urban settings has revolutionized pipeline installation methods, especially in densely populated areas. Case studies like the Directional Boring Toledo project highlight the benefits of Horizontal Directional Drilling (HDD). This technique allows for the installation of pipelines under streets and other obstacles without the need for extensive excavation, minimizing disruption to everyday life.

In the heart of an urban environment, where real estate is valuable, and traffic congestion is a constant challenge, HDD offers a precise and efficient solution. The technology has proven its worth by successfully installing large-diameter pipes for water, sewer, and gas applications without causing major road closures or disrupting local businesses. These case studies not only demonstrate the technical feasibility of Trenchless Technology but also its economic advantages, making it a preferred choice for urban pipeline infrastructure projects.