Custom automotive foam inserts are vital for securely transporting delicate car parts in Holland, Ohio. These tailored solutions, perfectly fitting specific dimensions, offer protective cradles for items like glass, mirrors, and engines, significantly reducing damage during shipping. By using these foam inserts, businesses overcome transportation challenges, ensuring intact delivery of valuable automotive inventory while promoting environmental sustainability through recyclable materials. This innovation has streamlined shipping processes, leading to cost savings and efficiency gains, solidifying Holland's position as a leader in both quality control and green practices within the automotive sector.

“In the realm of efficient and sustainable shipping, particularly within Holland, Ohio’s thriving automotive industry, customizable foam inserts are emerging as a game-changer. This article delves into the growing necessity for recyclable automotive foam inserts for shipping, highlighting their role in safeguarding delicate components during transit. We explore how tailored foam solutions enhance protection, reduce waste, and contribute to a greener future, especially with Holland’s commitment to fostering an eco-conscious environment. By examining real-world applications, we uncover the significant benefits these custom automotive foam inserts bring to local businesses.”

- Understanding the Need for Recyclable Foam Inserts in Shipping

- Customizing Automotive Foam Inserts for Safe Fragile Parts Transportation

- The Impact and Benefits of Using Foam Inserts in Holland, Ohio's Automotive Industry

Understanding the Need for Recyclable Foam Inserts in Shipping

In today’s eco-conscious world, the demand for sustainable and recyclable shipping solutions is higher than ever, especially within industries that handle delicate and fragile items like automotive parts. The traditional foam inserts used in shipping have often been non-biodegradable and challenging to recycle, creating a significant environmental impact. This has prompted businesses, particularly those specializing in automotive foam inserts for shipping in Holland, Ohio, to seek out greener alternatives.

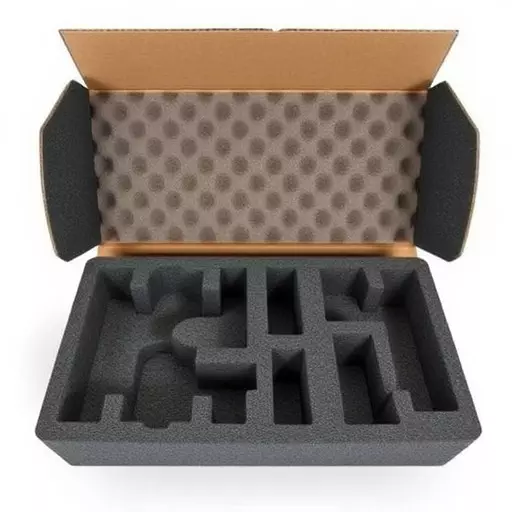

Custom automotive foam inserts offer an innovative solution by providing both protection for fragile parts during transit and the potential for eco-friendly recycling. These custom-designed inserts can adapt to the unique shapes and sizes of various automotive components, ensuring they arrive at their destination without damage. This not only reduces waste but also supports a more circular economy, where materials are reused and recycled, ultimately benefiting both businesses and the environment.

Customizing Automotive Foam Inserts for Safe Fragile Parts Transportation

When it comes to transporting fragile automotive parts, custom automotive foam inserts play a pivotal role in ensuring safety during transit. These specialized inserts are designed with precision to fit specific part dimensions, providing a secure and protective environment for delicate components. By customizing these foam inserts for shipping in Holland, Ohio, businesses can significantly reduce the risk of damage, especially for high-value or intricate auto parts.

The process involves creating precise cutouts and shaping the foam to perfectly cradle the automotive part, offering both stability and shock absorption. This customization ensures that fragile items like glass, mirrors, or intricate engine components are handled with utmost care, minimizing the potential for breakage during shipping. With custom automotive foam inserts, businesses can seamlessly navigate the challenges of transportation, ensuring their valuable inventory arrives safely at its destination.

The Impact and Benefits of Using Foam Inserts in Holland, Ohio's Automotive Industry

In Holland, Ohio’s thriving automotive industry, the use of recyclable foam inserts for shipping has gained significant traction. These custom automotive foam inserts play a pivotal role in protecting fragile automotive parts during transit, ensuring they arrive at their destinations undamaged. The benefits are manifold; not only do they safeguard valuable components, but they also contribute to the environmental sustainability that the region prides itself on. By utilizing recyclable materials, Holland’s automotive businesses can reduce their carbon footprint and meet the growing demand for eco-friendly practices within the industry.

Furthermore, the implementation of foam inserts has streamlined shipping processes, leading to cost savings and efficiency gains. Automotive manufacturers and suppliers in Holland can now package parts with precision, minimizing the risk of damage and associated costs. This innovation has fostered a culture of responsible production and distribution, where protecting products goes hand in hand with adopting sustainable solutions. As a result, Holland’s automotive sector stands out as a leader in both quality control and environmental stewardship.