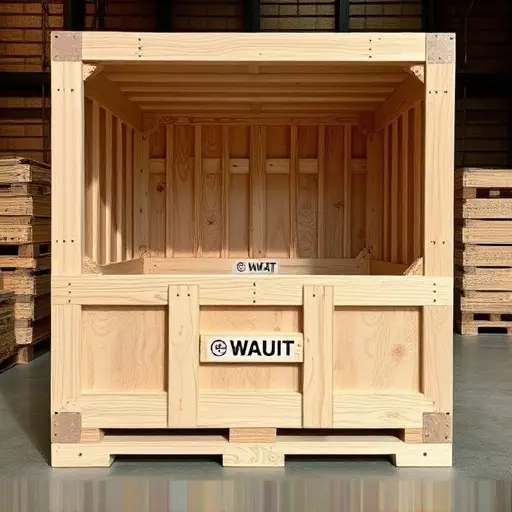

Custom Wood Crates Holland Ohio offers superior quality heavy-duty wooden crates utilizing professional wood crate manufacturing techniques. Their innovative use of compression-resistant EPP foam enhances custom wood crates holland ohio durability, providing exceptional shock absorption and crush resistance. These high-end crates protect delicate items better than standard market options, making them ideal for businesses seeking top-tier protection for their goods.

“Unleash the power of protection with compression-resistant EPP foam, a game-changer in the realm of wood crate manufacturing. This innovative material is transforming the way we safeguard fragile items during transit. In this article, we explore its unique properties and benefits, particularly highlighting its impact on custom wood crates Holland Ohio relies on for durability. From professional wood crate manufacturing to heavy-duty applications, discover how EPP foam enhances protection, ensuring goods arrive intact, even in challenging conditions.”

- Understanding Compression-Resistant EPP Foam: Properties and Benefits

- Custom Wood Crates Holland Ohio: How EPP Foam Enhances Durability

- Professional Wood Crate Manufacturing: Integrating EPP for Optimal Protection

- Heavy-Duty Wooden Crates: Case Studies Using Compression-Resistant EPP Foam

Understanding Compression-Resistant EPP Foam: Properties and Benefits

Compression-resistant EPP foam is a game-changer in the world of custom wood crate manufacturing. This innovative material offers unparalleled strength and durability, making it ideal for heavy-duty wooden crates used in demanding industries like shipping and logistics. In contrast to traditional foams, EPP exhibits exceptional resistance to compression, ensuring that the content inside remains secure during transit, even under intense pressure.

For professionals crafting wood crates in Holland, Ohio, or beyond, incorporating EPP foam can significantly enhance product quality and customer satisfaction. Its lightweight yet robust nature simplifies crate design while reducing material costs. Moreover, EPP’s excellent shock absorption properties further protect fragile items, making it a preferred choice for specialized wooden crates tailored to specific client needs, whether for machinery, electronics, or other sensitive cargo.

Custom Wood Crates Holland Ohio: How EPP Foam Enhances Durability

Custom Wood Crates Holland Ohio relies on compression-resistant EPP foam to significantly enhance the durability of their heavy-duty wooden crates. This innovative material plays a pivotal role in ensuring that the crates not only withstand the rigors of transportation but also retain their structural integrity over time.

EPP foam, known for its lightweight yet robust nature, provides exceptional shock absorption and crush resistance. By integrating this foam into their crate designs, Custom Wood Crates Holland Ohio can produce superior quality wooden crates capable of protecting delicate items during transit. This professional wood crate manufacturing process results in more reliable and long-lasting containers that are a cut above the standard options available in the market, catering to businesses seeking top-tier protection for their goods.

Professional Wood Crate Manufacturing: Integrating EPP for Optimal Protection

In the world of professional shipping and logistics, ensuring the safe transit of delicate goods is paramount. This is where custom wood crate manufacturing comes into play, especially for companies like those based in Holland, Ohio, known for their expertise in creating heavy-duty wooden crates. By integrating Expansion Polystyrene (EPP) foam into their designs, these manufacturers are revolutionizing protection against impact and compression during transit. EPP’s lightweight yet robust nature makes it an ideal material for custom wood crates, ensuring that fragile items arrive at their destination unscathed.

Professional wood crate manufacturers in Holland, Ohio, understand the value of adapting to modern shipping challenges. They recognize that traditional crate designs may not provide sufficient protection against the rigorous handling and jostling often encountered during transportation. Thus, they’ve adopted innovative techniques, utilizing EPP foam to create specialized wooden crates tailored to specific product requirements. This integration offers enhanced cushioning and impact absorption, making heavy-duty wooden crates more effective than ever in safeguarding valuable cargo.

Heavy-Duty Wooden Crates: Case Studies Using Compression-Resistant EPP Foam

In the realm of heavy-duty packaging solutions, custom wood crates from Holland, Ohio, have long been a cornerstone for professional wood crate manufacturing. These sturdy crates are designed to withstand rigorous handling and transportation conditions, making them indispensable in industries like construction, automotive, and electronics. When it comes to enhancing durability, compression-resistant EPP foam plays a pivotal role. Integrating this innovative material into the design of heavy-duty wooden crates offers a game-changer in protection for delicate items during transit.

Case studies from various sectors highlight the effectiveness of EPP foam in preserving goods within these custom wood crates. For instance, in the automotive industry, where precision and safety are paramount, compression-resistant EPP foam has been instrumental in securing sensitive electronic components during shipping. Similarly, construction companies have benefited from the superior shock absorption properties of EPP foam, ensuring that fragile equipment arrives at sites intact. This professional wood crate manufacturing approach, combining robust wooden structures with advanced EPP foam, sets a new standard for protecting valuable cargo, catering to the demands of modern logistics in the bustling business landscape.