Regular Kitchen Suppression Inspections in Spring Lake are crucial for commercial kitchens to ensure fire safety and comply with regulations. These inspections verify the functionality of fire suppression systems, including agent storage, sprinkler systems, alarms, detectors, control valves, piping, and servicing records. By addressing potential issues early, businesses protect lives, property, employees, and customers, ensuring efficient emergency deployment of these systems to minimize damage. Regular checks by qualified professionals are vital for maintaining optimal kitchen safety.

In the heart of any culinary hub, including Spring Lake, a robust kitchen suppression system is not just an added convenience—it’s a critical safety measure. This article delves into the intricacies of kitchen suppression inspection in Spring Lake, exploring the fire suppression compliance checks essential for maintaining a safe cooking environment. From understanding the system’s role to identifying key components, we guide you through best practices ensuring your kitchen remains a haven free from culinary disasters.

- Understanding Kitchen Suppression Systems: Their Role and Importance

- The Need for Regular Inspection and Maintenance

- Key Components to Assess During a Fire Suppression Compliance Check

- Ensuring Safety: Best Practices for Effective Kitchen Suppression Inspection in Spring Lake

Understanding Kitchen Suppression Systems: Their Role and Importance

Understanding Kitchen Suppression Systems is paramount in ensuring safe and compliant upgrades to any commercial or residential space. These systems play a critical role in mitigating kitchen fires, which are among the most common and severe types of domestic blazes. A Kitchen Suppression Inspection in Spring Lake not only verifies that such systems are present and functional but also ensures they meet local fire suppression compliance standards. Regular inspections are essential to guard against potential hazards, as faulty or outdated equipment can lead to catastrophic failures during a fire event.

Moreover, these checks help identify areas for upgrade or replacement, ensuring that kitchen suppression systems remain effective in suppressing or delaying the spread of fires. This proactive approach aligns with broader safety protocols and is crucial for maintaining a safe cooking environment, protecting lives, and minimizing property damage.

The Need for Regular Inspection and Maintenance

Regular inspections and maintenance are crucial aspects of ensuring fire safety in any facility, including commercial kitchens in Spring Lake. Kitchen suppression systems, designed to extinguish fires quickly, require routine checks to maintain their effectiveness and reliability. These inspections go beyond simple visual assessments; they involve thorough testing and verification that every component functions as intended. By conducting kitchen suppression system inspections, businesses can identify potential issues or failures before they become critical, thus enhancing fire safety compliance.

Fire suppression compliance checks are essential not just for regulatory purposes but also to protect the property, employees, and customers within the facility. Regular maintenance helps keep these systems in optimal condition, ensuring they deploy promptly and efficiently when needed. In the event of a fire, a well-maintained kitchen suppression system can significantly reduce damage, minimize business disruption, and save lives.

Key Components to Assess During a Fire Suppression Compliance Check

During a fire suppression compliance check in Spring Lake, several key components need meticulous assessment to ensure the kitchen suppression system’s effectiveness and adherence to safety standards. These include examining the fire suppression agents, verifying their proper storage and handling, and inspecting the sprinkler system for any leaks or blockages. The condition of detecting devices such as alarms and detectors is vital; they must be functional and interconnected for an efficient evacuation.

Additionally, checking the system’s control valves and ensuring they are easily accessible and in good working order is crucial. The piping network should be free from corrosion and damage, with clear markings indicating its path. Regular maintenance records should also be reviewed to guarantee that all inspections and servicing have been completed as per the manufacturer’s guidelines. These comprehensive checks ensure not just compliance with fire suppression regulations but also the kitchen’s safety during potential fires.

Ensuring Safety: Best Practices for Effective Kitchen Suppression Inspection in Spring Lake

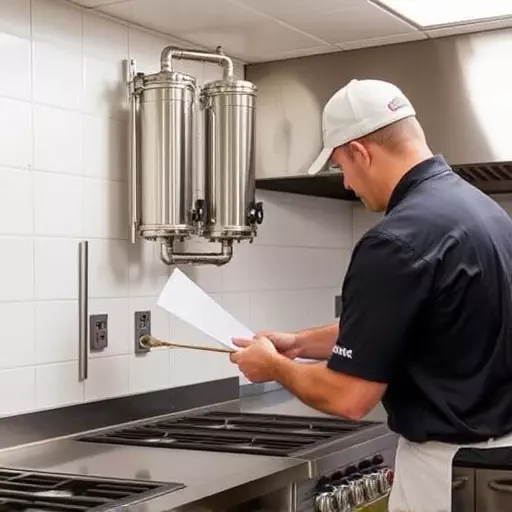

In Spring Lake, ensuring safety in commercial kitchens is paramount, especially when considering system upgrades. A thorough Kitchen Suppression Inspection becomes an indispensable practice to guarantee fire suppression systems function optimally and comply with regulations. This inspection process involves a detailed evaluation of each component within the kitchen suppression system, from detectors and sprinklers to control panels and piping networks. By employing qualified professionals, business owners can rest assured that their establishments meet the highest safety standards.

Best practices dictate regular, mandated checks to identify potential issues or flaws in the fire suppression system. These inspections not only verify the system’s integrity but also provide an opportunity to address any necessary maintenance or upgrades promptly. Staying proactive in Fire Suppression Compliance Checks is key to mitigating risks and protecting both patrons and staff from the devastating consequences of kitchen fires.