The Kitchen Suppression Inspection process in Spring Lake is a mandatory safety protocol for commercial kitchens to adhere to local fire codes and NFPA guidelines, ensuring protection of lives and property. This inspection encompasses all aspects of the kitchen suppression system, including detectors, controls, actuators, and suppressant agents, with certified professionals conducting thorough evaluations to verify optimal functionality in emergencies. It is recommended that Spring Lake businesses schedule these inspections during off-peak hours for a comprehensive assessment. These compliance checks are not just about meeting safety regulations but also about ensuring that specialized fire suppression systems, such as wet chemical or dry powder extinguishers, are operational and appropriately calibrated for the kitchen's specific needs. Regular maintenance and detailed documentation are essential parts of this process, which aims to maintain the integrity of commercial kitchen operations and provide a safeguard against potential fire incidents. Engaging professionals for these inspections is a proactive measure that guarantees businesses in Spring Lake are equipped with robust defense mechanisms that comply with the highest safety benchmarks.

When it comes to safeguarding commercial kitchens from fire hazards, regular inspections of the kitchen suppression system are indispensable. In Spring Lake, adhering to the protocols of Kitchen Suppression Inspection Spring Lake is not just a precautionary measure but a vital part of maintaining public safety and protecting business operations. This article delves into the critical aspects of kitchen fire suppression systems, highlighting their key components, functions, and the importance of compliance checks. We will guide you through the essential Step-by-Step Guide to Zone Testing in Kitchen Suppression Systems, ensuring that your establishment remains protected against unexpected fires.

- Understanding the Importance of Regular Kitchen Suppression System Inspections in Spring Lake

- Key Components and Functions of a Kitchen Suppression System

- Step-by-Step Guide to Zone Testing in Kitchen Suppression Systems

- Ensuring Fire Suppression Compliance Checks for Commercial Kitchen Safety

Understanding the Importance of Regular Kitchen Suppression System Inspections in Spring Lake

In Spring Lake, maintaining the safety and integrity of commercial kitchens is paramount, especially given the potential risks fire poses to such establishments. Regular kitchen suppression system inspections are a critical component of this safety protocol. These inspections, known as ‘Kitchen Suppression Inspection Spring Lake,’ are not merely compliance checks; they are a vital measure to ensure fire suppression systems function optimally when needed. Business owners and operators must adhere to strict fire suppression compliance checks to safeguard their operations and protect staff and patrons. A well-maintained kitchen suppression system can significantly reduce the risk of fire damage, which is why establishing a consistent inspection schedule is essential. These inspections are conducted by certified professionals who assess the entire system, including all detectors, controls, actuators, and fire suppressant agents, to verify their proper functioning and compliance with local fire codes and standards. By scheduling these inspections during spring or fall, when kitchens transition between high-use periods, businesses in Spring Lake can ensure their fire suppression systems are prepared for the year ahead. This proactive approach not only complies with safety regulations but also offers peace of mind, knowing that in the event of a fire emergency, the kitchen suppression system inspection will have effectively reduced potential harm and damage.

Key Components and Functions of a Kitchen Suppression System

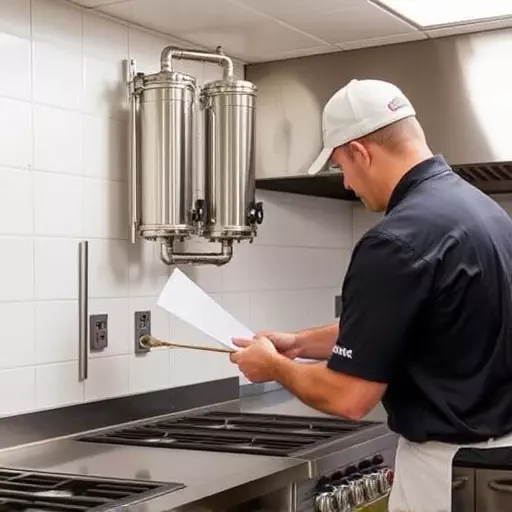

When it comes to safeguarding commercial kitchens from fire hazards, a kitchen suppression system is an indispensable component. These systems are designed with key components such as fire extinguishers, detection devices, and gas-based suppression agents specifically tailored for kitchen environments. The suppression system’s function begins with heat or smoke detection, which triggers an alarm to alert occupants of a potential fire. Upon activation, the system discharges a chemical agent that effectively extinguishes flames without damaging kitchen equipment, which is highly susceptible to fire due to the presence of cooking oils and combustible materials. Regular inspections by certified professionals are crucial to ensure the system’s components are in optimal working condition. Kitchen suppression system inspection in Spring Lake should adhere to strict guidelines set forth by the National Fire Protection Association (NFPA) and local fire codes, ensuring compliance with regulations and providing peace of mind for business owners. These inspections not only verify the functionality of the suppression system but also assess the integrity of related equipment, such as ductwork and exhaust systems, which are critical to the overall effectiveness of the fire suppression setup in a kitchen setting. It is imperative that these systems undergo routine maintenance and inspection to ensure they will perform as intended during an emergency, thereby protecting both lives and property. Regular kitchen suppression system inspection is not just a compliance check; it is a proactive measure that can prevent catastrophic events.

Step-by-Step Guide to Zone Testing in Kitchen Suppression Systems

When conducting a thorough kitchen suppression system inspection in Spring Lake, it is imperative to adhere to a step-by-step approach to ensure fire suppression compliance checks are met. The first step involves a visual inspection of the entire system to identify any visible signs of wear, damage, or improper installation. This includes examining all nozzles, pipes, and fire suppression agents for any leaks or blockages that could compromise the system’s effectiveness. Each component must be checked for proper function, including the detection mechanism, which should be sensitive to different types of fires that can occur in a kitchen environment.

Upon verifying the physical integrity of the system, the next phase is to perform a series of operational tests. These tests ensure that the suppression agents are dispensed correctly and that the system’s activation mechanisms work without delay. This involves triggering the system to confirm that it releases the suppressant evenly throughout the kitchen space. Additionally, it is crucial to validate that the system shuts off as intended after the release of suppressants. After these operational checks, a record of the inspection and test results should be documented, noting any components that require maintenance or replacement to maintain compliance with local fire safety regulations. Regular adherence to this step-by-step guide for zone testing in kitchen suppression systems is vital for ensuring the safety and integrity of the system, thereby protecting both commercial establishments and their patrons from potential fire hazards.

Ensuring Fire Suppression Compliance Checks for Commercial Kitchen Safety

When it comes to commercial kitchen safety, regular inspections of kitchen suppression systems are non-negotiable. In Spring Lake and beyond, adhering to stringent fire suppression compliance checks is vital to safeguard lives and property. These checks ensure that the kitchen suppression system inspection meets the standards set forth by local fire codes and NFPA (National Fire Protection Association) guidelines. The process involves a meticulous examination of the system’s components, including detection devices, control panels, actuators, and agents like wet chemical or dry powder extinguishers. It is imperative to verify that these systems are not only functional but also configured correctly for the specific type of kitchen, considering the unique risks associated with cooking processes involving open flames and hot surfaces. Ensuring compliance is a continuous responsibility that cannot be overstated; it involves periodic maintenance, documentation of each inspection, and updates as per new safety regulations. Kitchen operators in Spring Lake must recognize that compliance is not just about ticking a box; it’s about creating a safe environment for their staff and patrons. By maintaining a well-maintained kitchen suppression system, establishments can significantly reduce the risk of fire damage and ensure the continuity of their business operations should an emergency arise. Regular inspections conducted by certified professionals not only comply with legal requirements but also provide peace of mind, knowing that in the event of a fire, the kitchen has a robust defense mechanism in place.