Steel packaging solutions have become a cornerstone of sustainable logistics, offering robust, reusable, and recyclable containers that reduce environmental impact while ensuring product safety during global transportation. These solutions are engineered with precision to minimize waste and maximize payload efficiency, featuring foam inserts that provide eco-conscious cushioning without compromising on protection. The durability of steel minimizes replacement needs, thus lowering the environmental footprint associated with packaging. Companies adopting these sustainable practices benefit from cost savings, meet corporate social responsibility goals, and showcase a commitment to innovation and environmental care, positioning themselves as leaders in sustainable logistics. The addition of foam inserts further aligns with this sustainability focus, offering a blend of robust product protection and responsible stewardship of the environment, all while meeting the unique needs of different products. These advancements underscore the industry’s dedication to adopting eco-friendly materials and processes, exemplifying how steel packaging solutions contribute to the circular economy and support global sustainability goals.

Steel packaging with foam inserts represents a significant advancement in material handling, merging robustness and eco-conscious design. This article delves into the multifaceted benefits of these innovative solutions, showcasing how they maximize efficiency and sustainability within modern supply chains. We explore the transformative role of steel containers, enhanced by cutting-edge foam inserts that provide superior protection for delicate items. Additionally, we examine the sustainable steel packaging movement, highlighting custom options that cater to a variety of needs. Through case studies and expert insights, we reveal why steel packaging with foam inserts stands out in terms of protection and durability, and how it aligns with the broader goals of environmental stewardship and economic efficiency. Join us as we uncover the practical advantages and design considerations that make these solutions a pivotal choice for businesses prioritizing both performance and planet.

- Maximizing Efficiency and Sustainability with Custom Steel Packaging Solutions

- The Role of Steel Containers in Modern Supply Chains

- Innovative Foam Inserts Enhancing the Protection of Steel Packaging

- Designing Eco-Friendly: The Sustainable Steel Packaging Movement

- Why Steel Packaging with Foam Inserts Stands Out in Protection and Durability

- Customization Options for Steel Packaging to Meet Unique Needs

- Case Studies: Success Stories of Steel Packaging Solutions with Foam Inserts

Maximizing Efficiency and Sustainability with Custom Steel Packaging Solutions

In the realm of logistics and product protection, the adoption of sustainable steel packaging solutions is a pivotal stride in the journey toward environmental responsibility. Custom steel packaging, engineered to fit the precise dimensions of the items they contain, significantly reduces material waste and maximizes payload efficiency. These bespoke containers are not only tailored for optimal protection during transit but also designed with sustainability in mind, often being fully recyclable and reusable. The durability of steel as a packaging material ensures longevity, minimizing the frequency of replacement and the associated environmental impact. Furthermore, the integration of foam inserts within these custom solutions provides cushioning that is both effective and environmentally friendly, further enhancing the protection of goods while upholding sustainable practices.

The benefits of implementing sustainable steel packaging extend beyond mere product security. Businesses leveraging these solutions can experience a reduction in overall packaging costs due to improved material utilization. The robustness of steel packaging also means that fewer resources are required to achieve the same level of protection offered by less durable materials. This shift towards more efficient and sustainable practices not only aligns with corporate social responsibility objectives but also positions companies at the forefront of innovation, demonstrating a commitment to both profitability and planetary health. The strategic use of foam inserts within these packages complements the sustainability narrative, offering a harmonious balance between protection and environmental stewardship.

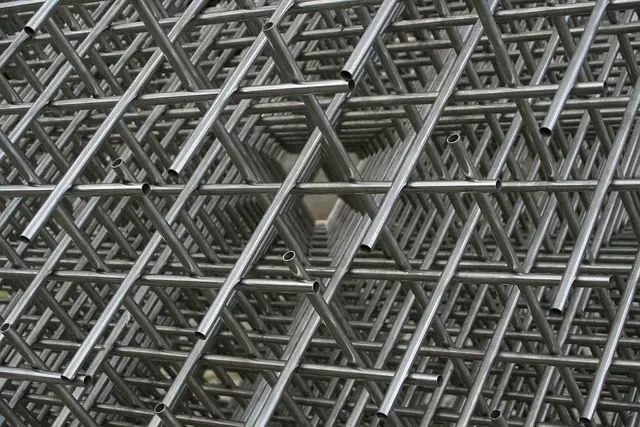

The Role of Steel Containers in Modern Supply Chains

Steel containers have become a cornerstone in modern supply chains, offering robust and reliable packaging solutions that meet the rigorous demands of transportation and storage across various industries. These containers provide an exceptional balance of protection and durability, ensuring that products arrive undamaged, even under challenging conditions. The use of sustainable steel packaging solutions is gaining traction as businesses increasingly prioritize environmental stewardship. Steel’s inherent properties make it highly recyclable and less dependent on non-renewable resources compared to other materials. This sustainability aspect aligns with the growing global commitment to reducing carbon footprints and minimizing waste, making custom steel packaging an attractive option for companies looking to enhance their eco-friendly practices without compromising on the security of their goods. The adaptability of these containers allows them to be tailored to the specific needs of each product, offering a level of customization that ensures optimal protection during transit. As such, steel containers play a pivotal role in the logistics sector, enabling a more sustainable flow of goods from manufacturers to end consumers, thereby solidifying their position as an indispensable element in modern supply chains.

Innovative Foam Inserts Enhancing the Protection of Steel Packaging

Steel packaging solutions have long been celebrated for their durability and sustainability, with sustainable steel packaging emerging as a front-runner in environmentally conscious industries. The integration of innovative foam inserts has further augmented the protective capabilities of these containers. These custom steel packaging options are designed to safeguard delicate contents during transit, ensuring that products arrive intact regardless of handling or shipping conditions. The foam inserts, crafted from advanced materials, provide a shock-absorbing barrier against impacts and vibrations, reducing the risk of damage. This synergy between robust steel containers and precision-cut foam inserts offers a dual-layered defense mechanism that protects goods from various types of physical stress. Moreover, these custom solutions are tailored to fit an array of products, ensuring optimal protection for each item’s unique dimensions and fragility levels. The result is a packaging system that not only upholds the principles of sustainability but also significantly enhances the overall efficiency and reliability of logistics operations. This advancement in steel packaging with foam inserts stands as a testament to the ongoing innovation within the industry, underscoring the commitment to safeguard products while maintaining an environmentally friendly approach.

Designing Eco-Friendly: The Sustainable Steel Packaging Movement

In the realm of sustainable packaging, steel packaging solutions have emerged as a robust and environmentally conscious choice for businesses looking to minimize their carbon footprint. The sustainable steel packaging movement is gaining momentum as companies recognize the inherent benefits of using steel containers over traditional materials. Steel’s exceptional durability and recyclability contribute significantly to its status as an eco-friendly option, with the ability to be reused and repurposed countless times without losing quality or integrity. Custom steel packaging not only offers a high level of protection for products during transit but also aligns with the principles of a circular economy by facilitating easy recycling at the end of its lifecycle. This commitment to sustainability ensures that these packaging solutions can be efficiently reintroduced into the manufacturing stream, reducing waste and conserving natural resources. Furthermore, the lightweight design of modern steel packaging reduces transportation emissions, making it an ideal solution for both environmental stewardship and operational efficiency.

The shift towards sustainable steel packaging is also driven by advancements in technology that enhance the functionality and design of these containers. Customization options allow for tailored solutions that cater to a wide array of product types, ensuring optimal protection during storage and shipping. The use of foam inserts within these steel containers adds an additional layer of security, safeguarding delicate items from shocks, vibrations, and other potential hazards. This integration of innovative materials and design principles underscores the industry’s dedication to creating packaging that is both resilient and kind to the environment. As a result, businesses are increasingly turning to custom steel packaging as a symbol of their commitment to sustainable practices and corporate responsibility.

Why Steel Packaging with Foam Inserts Stands Out in Protection and Durability

Steel packaging solutions have long been lauded for their robustness and ability to provide superior protection to products during transportation and storage. Enhanced with foam inserts, these containers offer unparalleled security against impacts, vibrations, and environmental factors that can compromise product integrity. The combination of steel’s inherent strength and the customizable cushioning properties of foam results in a packaging system that stands out for its protection and durability. Steel’s resilience is not only a testament to its material but also to the sustainable practices embedded within sustainable steel packaging production. These solutions are designed with environmental stewardship in mind, using recyclable materials and energy-efficient manufacturing processes. Unlike some alternative packaging options, custom steel packaging can be repeatedly recycled without loss of quality, ensuring a minimal carbon footprint. The bespoke foam inserts add to the sustainability narrative by providing precise fitting and reducing the need for excessive packaging material. This synergy between steel and foam not only safeguards products but also aligns with contemporary eco-conscious consumer preferences, making it an ideal choice for companies looking to reduce their environmental impact while maintaining high standards of product protection.

Customization Options for Steel Packaging to Meet Unique Needs

Steel packaging solutions offer a robust and sustainable alternative for businesses looking to protect their products during transit. With the rise of environmental consciousness, the demand for eco-friendly packaging options has surged, making sustainable steel packaging a focal point in the industry. Customization is a key aspect of these steel packaging solutions, enabling companies to tailor the packaging to meet their unique needs and product specifications. These custom steel packaging options range from size and shape modifications to incorporating specialized coatings for enhanced protection against environmental factors or compatibility with various products.

The foam inserts within these custom steel packaging designs are engineered to provide unparalleled shock absorption, ensuring that delicate items arrive intact and undamaged. This level of customization ensures that each package can accommodate the specific dimensions and fragility of the contents it houses. The integration of advanced manufacturing techniques allows for precise foam cutting and insertion, which not only protects the product but also reduces waste, further aligning with sustainability goals. These bespoke packaging solutions are not only a testament to innovation in the field of sustainable steel packaging but also underscore the commitment to safeguarding products while honoring environmental responsibilities.

Case Studies: Success Stories of Steel Packaging Solutions with Foam Inserts

In the realm of sustainable packaging, steel packaging solutions with foam inserts have emerged as a robust choice for businesses seeking to safeguard their products during transit while adhering to eco-friendly practices. A prime example of this is the case study of a leading electronics manufacturer that transitioned from traditional plastic packaging to custom sustainable steel packaging. This move not only reduced the company’s carbon footprint but also significantly enhanced product protection, thanks to the precision-engineered foam inserts that are tailored to each product’s unique dimensions and fragility. The results were clear: a marked decrease in damage claims and a notable increase in customer satisfaction.

Another success story comes from the beverage industry, where a well-established brewery optimized its packaging strategy by employing steel cans with custom foam inserts. This change allowed for better stackability and reduced the risk of product deformation during shipping. The steel cans’ superiority in protecting against corrosion and temperature fluctuations, combined with the effective cushioning provided by the foam inserts, ensured that the beverages arrived at retailers in pristine condition. This led to a significant reduction in losses and a substantial improvement in supply chain efficiency. Both cases underscore the benefits of steel packaging solutions with foam inserts, highlighting their role in enhancing product integrity, reducing waste, and promoting sustainability.

In conclusion, the synergy between steel packaging solutions and advanced foam inserts represents a significant leap forward in both efficiency and sustainability within the packaging industry. Steel’s inherent durability and recyclability align seamlessly with the eco-friendly ethos of sustainable steel packaging practices, offering a compelling alternative to less resilient options. The customization capabilities of these solutions ensure that they can meet a wide array of protection requirements, as evidenced by the impressive case studies highlighted. As businesses continue to seek out responsible and protective packaging methods, steel packaging with foam inserts stands out as an optimal choice for safeguarding products during transit. Embracing this dual-pronged approach not only enhances product security but also contributes to a more sustainable future, making it a smart investment for companies prioritizing both performance and planet.