Steel packaging solutions have become a key player in securing safety and sustainability for battery storage and transport, offering robust containers that protect against hazards like short-circuiting and overheating. These steel containers are engineered to be durable, resisting corrosion to extend the batteries’ shelf life and minimize environmental risks during disposal and recycling. The focus on sustainable steel packaging emphasizes reusability, waste reduction, and resource conservation, fitting within the circular economy model, where the high recyclability of steel supports a closed-loop system that reduces reliance on new materials and lowers the carbon footprint of packaging production. As the world shifts towards sustainable energy storage, these steel solutions are at the forefront, providing safe and eco-friendly options for various battery types, while complying with environmental regulations. The customizable nature of these steel containers allows them to cater to different battery chemistries and sectors, ensuring they remain relevant amidst advancements in battery technology and the growing demand for green practices in the energy storage industry.

Exploring the transformative role of steel packaging in the battery sector, this article delves into how advanced custom steel packaging solutions are enhancing both the safety and sustainability of battery storage. We will examine the innovative strides in sustainable steel packaging, tailored to meet a range of performance needs, and its significant impact on the evolution of battery technology. The narrative unfolds across three key sections: “Maximizing Battery Safety and Sustainability with Custom Steel Packaging Solutions,” “The Role of Sustainable Steel Packaging in the Evolution of Battery Storage,” and “Innovations in Steel Packaging for Batteries: Tailoring Protection to Performance Needs.” Join us as we navigate the intricacies of this resilient shield for portable energy.

- Maximizing Battery Safety and Sustainability with Custom Steel Packaging Solutions

- The Role of Sustainable Steel Packaging in the Evolution of Battery Storage

- Innovations in Steel Packaging for Batteries: Tailoring Protection to Performance Needs

Maximizing Battery Safety and Sustainability with Custom Steel Packaging Solutions

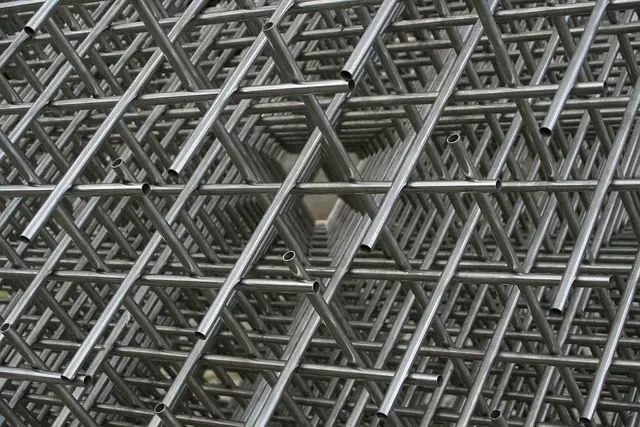

In the realm of battery storage and transport, prioritizing safety and sustainability is paramount. Custom steel packaging solutions offer a robust and reliable alternative to traditional materials, providing exceptional protection against potential hazards like short-circuiting, overheating, or physical damage that batteries might face. These solutions are engineered with durability in mind, ensuring that the batteries within are shielded from external impacts and environmental factors. The use of steel as a packaging material is particularly advantageous due to its inherent strength and resistance to corrosion, which not only safeguards the battery during transit but also extends its shelf life. Moreover, the adoption of sustainable steel packaging is a step towards reducing the environmental impact associated with battery disposal and recycling. These packages are designed to be reused multiple times, reducing waste and conserving resources. The lifecycle analysis of steel packaging indicates that it is highly recyclable and retains its properties even after being recycled, contributing to a closed-loop system where materials are kept in circulation, minimizing the need for virgin resources and lowering the carbon footprint associated with battery packaging production. By investing in sustainable steel packaging solutions, manufacturers and distributors can significantly enhance the safety and sustainability of battery handling, ensuring compliance with stringent regulations while also meeting the growing consumer demand for eco-friendly products.

The Role of Sustainable Steel Packaging in the Evolution of Battery Storage

The transition towards more sustainable energy storage solutions has been a significant driver in the evolution of battery technology. Among the critical components that facilitate this progression is the role of sustainable steel packaging. Steel, renowned for its durability and recyclability, serves as an ideal container for batteries due to its ability to protect the contents from environmental factors while ensuring safety during transportation and storage. Sustainable steel packaging solutions are at the forefront of this shift, offering custom steel packaging options that not only cater to the diverse needs of battery types but also adhere to stringent environmental standards. These solutions are designed with the end-of-life cycle in mind, ensuring that the packaging can be efficiently recycled without compromising the integrity of the materials involved. The adoption of sustainable steel packaging in the battery storage industry not only supports the circular economy by minimizing waste but also aligns with global sustainability goals. As energy demands continue to rise, the importance of safe, reliable, and eco-friendly packaging will become increasingly paramount, and steel packaging solutions are poised to play a pivotal role in this evolving landscape.

Innovations in Steel Packaging for Batteries: Tailoring Protection to Performance Needs

Innovations in steel packaging solutions for batteries have been pivotal in addressing the unique demands of safeguarding energy storage devices while promoting sustainability. The advancements in sustainable steel packaging have led to the development of custom steel packaging options that are tailored to meet specific performance needs, ensuring optimal protection without compromising on environmental responsibilities. These bespoke solutions are engineered to withstand the rigors of transport and handling, offering a robust alternative to traditional materials. The integration of advanced design techniques allows for precise control over the weight and thickness of the packaging, striking a balance between durability and resource efficiency. This not only enhances the safety of battery transportation but also contributes to a lower carbon footprint, aligning with the global shift towards greener practices in manufacturing and distribution. As battery technologies evolve, these steel packaging solutions continue to adapt, ensuring they remain at the forefront of performance and sustainability. The customizability of these steel containers means they can be optimized for various battery chemistries, including lithium-ion, lead-acid, and nickel-metal hydride, accommodating a wide range of applications from consumer electronics to electric vehicles. This adaptability ensures that as the battery industry grows and changes, steel packaging solutions will provide the necessary protection and support for the energy storage needs of today and tomorrow.

In conclusion, the transition to renewable energy sources necessitates advancements in battery storage and protection. The adoption of sustainable steel packaging solutions stands as a pivotal step in this direction, offering unparalleled safety and environmental stewardship. Custom steel packaging not only tailors protection to performance needs but also aligns with global sustainability goals. As the battery industry continues to innovate, these robust packaging options will undoubtedly play a crucial role in ensuring the efficient and safe storage of energy for a greener future.