This text emphasizes the importance of specialized steel packaging for safely transporting and storing hazardous materials, highlighting its strength, durability, and recyclability. Custom steel packaging, tailored to unique product needs, enhances security and brand image. Sustainable practices in steel manufacturing further reduce environmental impact, making these solutions a popular choice among eco-conscious businesses. By prioritizing durable, customizable, and environmentally friendly steel packaging, companies can ensure compliance, protect products, and contribute to a greener future.

In the realm of hazardous materials management, understanding the unique challenges and critical safety requirements is paramount. This article explores the transformative role of steel packaging solutions in addressing these concerns. From advantages like enhanced durability to sustainable steel packaging as a green alternative, we delve into how customizable options cater to specialized needs. Learn best practices for implementation, ensuring safety measures align with effective custom steel packaging strategies for various hazardous materials.

- Understanding Hazardous Materials and Their Packaging Needs

- The Advantages of Steel Packaging Solutions

- Sustainable Steel Packaging: A Green Alternative

- Customization Options for Specialized Hazardous Materials

- Implementing Steel Packaging: Best Practices and Safety Measures

Understanding Hazardous Materials and Their Packaging Needs

Understanding Hazardous Materials and Their Packaging Needs

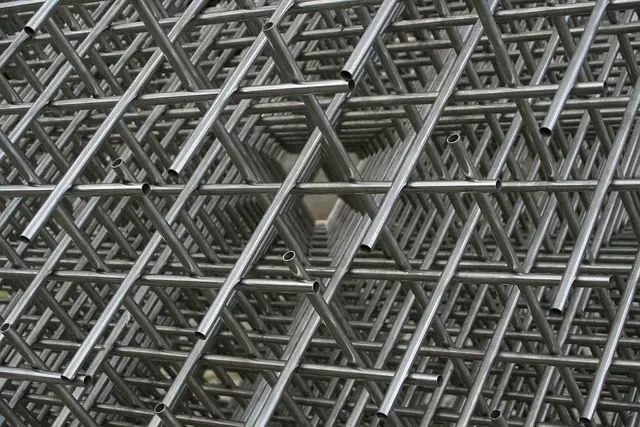

Hazardous materials, including chemicals, fuels, and pharmaceuticals, pose unique challenges when it comes to packaging. These substances demand specialized containment solutions that prioritize safety and compliance with stringent regulatory standards. Steel packaging solutions have emerged as a preferred choice due to their superior strength, resistance to corrosion, and ability to provide robust protection against leaks and spills.

Custom steel packaging plays a pivotal role in meeting the specific requirements of hazardous materials. Sustainable steel packaging options further enhance environmental considerations, offering a balance between safety and ecological responsibility. This versatility in custom steel packaging design ensures that each hazardous substance is securely contained, transported, and stored, minimizing risks to both people and the environment.

The Advantages of Steel Packaging Solutions

Steel packaging solutions offer a range of advantages, especially when it comes to hazardous materials. One of the key benefits is their superior strength and durability; steel can withstand extreme conditions, including high temperatures and pressure, making it ideal for safe transportation. This feature ensures that sensitive and potentially dangerous goods remain secure during transit, reducing the risk of leaks or damage.

Additionally, sustainable steel packaging is an eco-friendly option. Steel is a recyclable material, which means it can be reused multiple times without losing its structural integrity. Custom steel packaging is also a viable solution, allowing manufacturers to design specific containers tailored to their unique products’ dimensions and requirements. This level of customization enhances safety by ensuring the perfect fit, reducing movement inside the package, and providing superior protection for hazardous materials.

Sustainable Steel Packaging: A Green Alternative

In today’s world, where environmental sustainability is a paramount concern, the shift towards eco-friendly steel packaging solutions for hazardous materials is gaining significant traction. Traditional packaging options often contribute to environmental degradation, but sustainable steel packaging offers a promising alternative. This robust and versatile material is not only highly recyclable but also provides superior protection for dangerous goods during transportation. By embracing custom steel packaging, businesses can ensure compliance with safety regulations while reducing their ecological footprint.

The manufacturing process of sustainable steel packaging involves advanced techniques that minimize energy consumption and emissions, making it a greener choice. Moreover, its durability extends product lifespans, reducing the need for frequent replacements. This eco-conscious approach not only benefits the environment but also fosters brand image and appeals to environmentally conscious consumers.

Customization Options for Specialized Hazardous Materials

In the realm of hazardous material transportation and storage, steel packaging solutions offer unparalleled safety and security. One of the significant advantages is their ability to be customized for specialized needs. Custom steel packaging is a game-changer in this industry as it allows manufacturers and shipping companies to address unique challenges posed by different types of hazardous substances. From corrosive chemicals to flammable liquids, these customizable options ensure that each material receives the specific protection it requires.

Sustainable steel packaging has emerged as an eco-friendly alternative, providing both durability and versatility. Customization enables the creation of innovative designs that meet strict regulatory standards while incorporating sustainable practices. This approach not only guarantees the integrity of hazardous materials but also contributes to a greener future by promoting reusable and recyclable steel packaging solutions.

Implementing Steel Packaging: Best Practices and Safety Measures

Implementing Steel Packaging requires a strategic approach, especially when handling hazardous materials. The key lies in choosing the right steel packaging solutions that offer both durability and safety. Opting for sustainable steel packaging is not just an eco-conscious choice but also ensures compliance with environmental regulations. Start by understanding the specific needs of your hazardous materials, including their physical properties and potential risks. Customizing steel packaging to these specifications is crucial; a one-size-fits-all approach may compromise safety.

Consider factors like corrosion resistance, impact strength, and compatibility with handling equipment. Collaborate closely with manufacturers who can provide tailored designs and ensure they adhere to international standards for hazardous material containment. Regular inspections and maintenance of steel packaging are essential safety measures. This includes checking for signs of wear, damage, or corrosion, promptly replacing any defective containers to maintain the highest level of protection throughout their lifecycle.