In Holland, Ohio, the competitive packaging industry has embraced CNC machining for custom, precise components, enhancing security and product protection. Steel racks with integrated locking mechanisms, enabled by CNC technology, offer optimal storage solutions. This approach streamlines operations, reduces waste, and improves efficiency, meeting modern packaging demands. Custom CNC-machined parts ensure tailored designs for specific products and layouts, deterring tampering and ensuring long-term safety. The benefits of this integration include enhanced security, reliable product protection, improved organization, reduced handling times, and cost-effectiveness.

“In today’s dynamic packaging landscape, the integration of advanced technologies like CNC machining is revolutionizing production processes. This article explores how CNC machining, specifically in Holland, Ohio, enhances the packaging industry with customized solutions. We delve into the creation of unique, secure packaging components using CNC-machined racks with locking mechanisms, offering improved product safety. Furthermore, we analyze the advantages of steel racks for efficient storage and organization, supported by a case study, and discuss future trends shaping packaging solutions.”

- The Role of CNC Machining in the Packaging Industry

- Customization: Creating Unique Packaging Components

- Secure Locking Mechanisms for Enhanced Product Safety

- Advantages of Steel Racks in Package Storage and Organization

- Case Study: Implementing CNC-Machined Racking Systems

- Choosing the Right Materials: Why Steel is Preeminent

- Future Trends: Evolving CNC Machining in Packaging Solutions

The Role of CNC Machining in the Packaging Industry

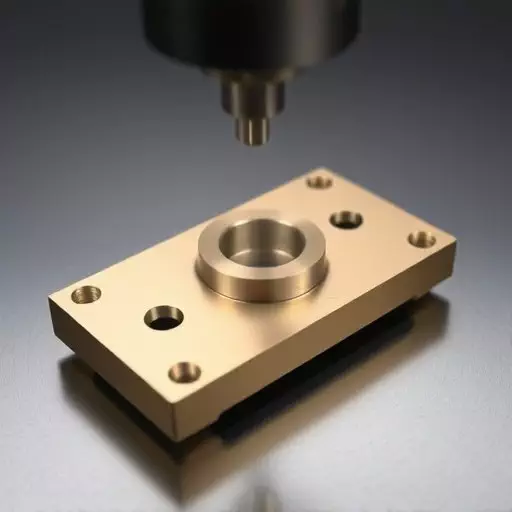

CNC machining plays a pivotal role in revolutionizing the packaging industry with its precision and efficiency. Based in Holland, Ohio, companies are leveraging CNC (Computer Numerical Control) machining to create custom cnc-machined packaging components that cater to specific product requirements. This advanced manufacturing process enables the production of intricate and highly customized parts, enhancing overall product quality and appeal.

The benefits of CNC machining in the packaging industry are manifold. It ensures consistency in part dimensions, leading to improved product reliability and reduced waste. Moreover, CNC machines can handle complex shapes and designs that traditional machining methods struggle with, fostering innovation in packaging design. This technology also allows for rapid prototyping, enabling businesses to test and refine their packaging concepts swiftly, ultimately driving cost savings and competitive edge in the market.

Customization: Creating Unique Packaging Components

In today’s competitive market, businesses are constantly seeking innovative ways to enhance their product presentation and storage solutions. This is where customization plays a pivotal role, especially in the packaging industry. By leveraging advanced manufacturing techniques like CNC machining, companies can create custom cnc-machined packaging components tailored to their unique requirements. Located in Holland, Ohio, many businesses benefit from this technology, enabling them to produce specialized steel racks with secure locking mechanisms that cater to their specific product needs and increase overall efficiency.

Custom CNC machining for the packaging industry offers numerous advantages. It allows for precise engineering of racks and containers, ensuring a perfect fit for various products. This customization results in reduced waste, optimized storage space, and enhanced product security. With CNC-machined components, businesses can create secure locking mechanisms that protect their goods from damage and theft, adding an extra layer of assurance to their packaging system. These benefits contribute to improved customer satisfaction and a competitive edge in the market.

Secure Locking Mechanisms for Enhanced Product Safety

In today’s competitive packaging industry, Holland, Ohio has emerged as a hub for innovative solutions. One such advancement is the integration of secure locking mechanisms in steel racks. These custom CNC-machined components offer unparalleled safety for products, especially in environments where stock manipulation and movement are frequent. By employing CNC machining technologies, manufacturers can produce precise, robust locking systems tailored to specific packaging requirements.

The benefits of this approach are manifold. Custom cnc-machined packaging components ensure a secure fit, preventing accidental or unauthorized access. This is particularly crucial for sensitive or valuable goods. Moreover, the precision engineering of CNC machining enhances overall product quality and reliability, ensuring that packaging remains intact during storage and transportation. Thus, businesses in Holland, Ohio can leverage these advanced locking mechanisms to safeguard their products, ultimately improving customer satisfaction and streamlining operations within the packaging industry.

Advantages of Steel Racks in Package Storage and Organization

Steel racks with secure locking mechanisms offer numerous advantages for package storage and organization, making them a top choice in the packaging industry. One of the key benefits is their durability; steel is an incredibly robust material that can withstand heavy loads and harsh conditions, ensuring your goods remain safe and secure. This is especially valuable in dynamic environments where packages may be frequently moved or exposed to varying temperatures.

Custom CNC machining plays a significant role here, enabling the creation of precise, tailored components for these racks. From intricate locking mechanisms to specific package-holding designs, CNC machining allows for the production of custom cnc-machined packaging components that optimize storage space and prevent damage. This precision engineering enhances overall efficiency in packing processes, offering benefits like improved organization, reduced handling time, and enhanced product protection.

Case Study: Implementing CNC-Machined Racking Systems

Choosing the Right Materials: Why Steel is Preeminent

When it comes to selecting materials for storage racks and locking mechanisms, steel stands out as a preeminent choice, especially when tailored through CNC machining. For industries like packaging in Holland, Ohio, the benefits are clear. Custom CNC-machined packaging components offer unparalleled precision and efficiency, ensuring every rack is designed to exacting standards. This level of customization allows for optimal storage solutions, catering to specific product needs and warehouse layouts.

Steel’s inherent strength and durability make it highly resistant to wear and tear, a critical factor in maintaining security over time. CNC machining further enhances these properties by enabling the creation of intricate locking mechanisms that deter tampering and ensure the safety of stored goods. This combination of advanced manufacturing and robust material translates directly into enhanced operational efficiency for packaging facilities, streamlining processes and reducing costs in the long run.

Future Trends: Evolving CNC Machining in Packaging Solutions