Automotive packaging design is at a crossroads of innovation and environmental responsibility. As the sector grapples with the challenges of sustainability, Toledo, Ohio emerges as a pivotal player in this transformative journey. This article delves into the intersection of cutting-edge materials and eco-conscious practices, spotlighting how local companies are leading the charge towards greener automotive packaging solutions. From the strategic reduction of waste in supply chains to the benefits of lightweighting, we explore the multifaceted approaches being taken to enhance sustainability within the industry. Join us as we examine the collaborative efforts of automotive manufacturers and packaging designers, and cast a visionary gaze towards the future of automotive packaging design, with particular attention to Toledo’s pioneering role.

- Innovative Materials in Automotive Packaging Design: A Focus on Toledo, Ohio

- The Role of Sustainability in Modern Automotive Packaging Solutions

- Case Study: Eco-Friendly Initiatives in Automotive Packaging Design by Toledo-Based Companies

- Strategies for Reducing Waste in Automotive Supply Chains from Design to Distribution

- The Impact of Lightweighting on Automotive Packaging Sustainability

- Collaborative Efforts: How Automotive Manufacturers and Packaging Designers are Partnering for a Greener Future

- The Future of Automotive Packaging Design: Predictions and Emerging Trends in Toledo, Ohio and Beyond

Innovative Materials in Automotive Packaging Design: A Focus on Toledo, Ohio

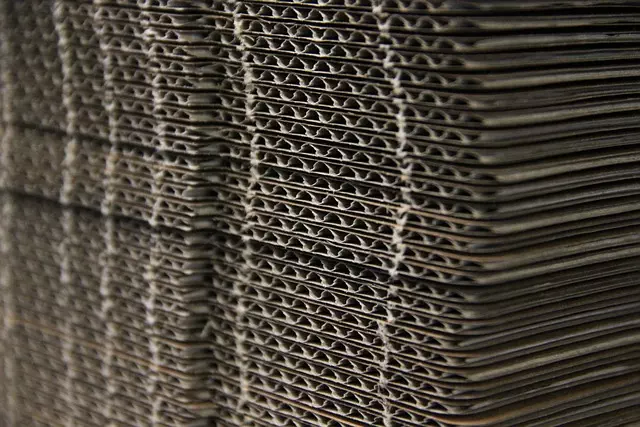

In Toledo, Ohio, the automotive industry is at the forefront of integrating innovative materials into automotive packaging design, setting a precedent for sustainability within the sector. The city’s strategic position in the automotive landscape has fostered an environment where companies are pushing the boundaries of traditional packaging solutions to reduce environmental impact. These advancements are not limited to the vehicles themselves but extend to the very packaging that protects and transports automotive components from production to dealerships. By leveraging locally sourced, recyclable, or biodegradable materials, Toledo-based initiatives are leading the charge in creating eco-friendly packaging designs that minimize waste and conserve resources. The focus on sustainability is evident as manufacturers explore alternatives to conventional plastics, such as plant-based polymers and bio-composites, which offer similar protective properties while being gentler on the environment. This shift towards greener practices not only aligns with global sustainability goals but also positions Toledo as a hub for innovative automotive packaging design.

The significance of Toledo in the realm of automotive packaging design is further underscored by the collaboration between local industry leaders, material scientists, and environmental experts. These partnerships are pivotal in driving research and development efforts that aim to refine packaging solutions to be as efficient and sustainable as possible. The use of advanced simulation software helps in optimizing packaging designs, ensuring that they provide maximum protection without unnecessary excess. Moreover, the commitment to circular economy principles is evident as companies work towards designing packaging that can be fully recycled or composted after use, further reducing the automotive industry’s ecological footprint. Toledo’s proactive stance in adopting sustainable packaging design practices not only benefits the environment but also serves as a model for other regions within the automotive industry to follow.

The Role of Sustainability in Modern Automotive Packaging Solutions

In the realm of modern automotive packaging solutions, sustainability plays a pivotal role in shaping design strategies to meet the evolving demands of the industry. The focus on sustainable practices within automotive packaging design, as exemplified by initiatives from Toledo Ohio and beyond, is driven by the need to mitigate environmental impact while optimizing functionality and efficiency. Designers are increasingly incorporating eco-friendly materials and innovative packaging configurations that reduce waste and energy consumption during production, distribution, and disposal. This approach not only aligns with regulatory standards but also resonates with consumer preferences for sustainable products. The implementation of advanced design methodologies in Toledo Ohio has led to the development of packaging solutions that are not only cost-effective but also minimize the carbon footprint associated with automotive manufacturing processes. By prioritizing sustainability, the automotive industry is paving the way towards a more responsible and future-proof approach to product packaging.

Furthermore, the integration of sustainable practices within automotive packaging design is catalyzing a shift towards circular economy principles. This paradigm emphasizes the reuse, recycling, and recovery of materials, ensuring that the lifecycle of packaging components is as closed-loop as possible. Companies in Toledo Ohio are at the forefront of this movement, experimenting with biodegradable materials, optimizing packaging weight to reduce resource use, and exploring take-back programs for post-consumer packaging. These efforts not only contribute to a cleaner environment but also position the automotive industry as a leader in sustainable innovation, setting a benchmark for other sectors to follow suit. The commitment to sustainability within automotive packaging design is a testament to the industry’s adaptability and foresight in addressing global environmental challenges.

Case Study: Eco-Friendly Initiatives in Automotive Packaging Design by Toledo-Based Companies

Toledo, Ohio, has emerged as a hub for innovative automotive packaging design, with local companies leading the charge in sustainability. One such company, EcoPac Innovations, based in Toledo, has made significant strides in developing eco-friendly packaging solutions specifically tailored for the automotive industry. Their approach focuses on reducing environmental impact by utilizing biodegradable materials and implementing recycling programs that ensure a minimal carbon footprint. The design process is centered around using renewable resources and cutting-edge technologies to create packaging that not only protects vehicles during transportation but also aligns with the industry’s growing commitment to sustainability. This commitment extends beyond their products, as EcoPac Innovations also partners with regional suppliers to source materials responsibly, further reinforcing Toledo’s role in setting new standards for automotive packaging design.

The initiatives undertaken by Toledo-based companies like EcoPac Innovations are not only reducing waste but are also driving the automotive industry towards a more sustainable future. These companies are pioneering the use of advanced, biodegradable composites that are both durable and compostable, marking a significant departure from traditional packaging materials. The city’s dedication to sustainability in automotive packaging design is evident in the way these local firms prioritize innovation and environmental stewardship. Their efforts not only enhance brand reputation but also meet the increasing consumer demand for eco-conscious products, positioning Toledo as a leader in sustainable automotive packaging design solutions.

Strategies for Reducing Waste in Automotive Supply Chains from Design to Distribution

The automotive industry’s commitment to sustainability has increasingly focused on the lifecycle of automotive packaging from design to distribution. In Toledo, Ohio, and beyond, manufacturers are implementing strategic measures to reduce waste across their supply chains. One such strategy involves optimizing the design of automotive packaging, which is where the journey towards sustainability begins. Innovative designers in Toledo and across the industry are pioneering eco-friendly materials and designs that not only protect vehicles effectively but also minimize excess material use. These designers leverage local expertise and resources to create packaging solutions that are both cost-effective and environmentally conscious. By employing advanced simulation technologies, they can predict and adjust packaging configurations to ensure optimal protection with minimal waste generation. This approach not only streamlines the supply chain by reducing handling and transportation costs but also significantly lowers the carbon footprint associated with production and disposal of packaging materials.

Furthermore, the industry is exploring collaborative efforts with suppliers to further enhance sustainability. By engaging in collaborative design processes, manufacturers and suppliers can jointly develop packaging solutions that are tailored to specific product needs while adhering to sustainable practices. This collaboration extends beyond design to encompass the entire lifecycle of the packaging, including its end-of-life disposal. Through shared knowledge and best practices, the automotive sector is setting new standards for packaging sustainability in Toledo, Ohio, and globally. The industry’s dedication to innovation in automotive packaging design is paving the way for a more sustainable future, where resource efficiency and environmental stewardship are integral parts of the supply chain.

The Impact of Lightweighting on Automotive Packaging Sustainability

Collaborative Efforts: How Automotive Manufacturers and Packaging Designers are Partnering for a Greener Future

Automotive manufacturers and packaging designers are forging strategic alliances in a collective bid to enhance sustainability within the automotive industry’s packaging sector. These partnerships are pivotal in driving innovation, as they leverage the expertise of both parties to create packaging solutions that are not only functional but also environmentally responsible. In Toledo, Ohio, a hub for the automotive industry, these collaborations are taking root, with local designers and manufacturers working hand-in-hand to refine automotive packaging design practices. The goal is to minimize waste and the environmental impact of packaging materials, which often includes plastics and other non-renewable resources. These efforts extend beyond mere compliance with regulations; they represent a proactive stance towards sustainability that aligns with consumer expectations for eco-friendly products and manufacturing processes. By integrating advanced design principles and sustainable materials, these partnerships are setting new standards for the industry, ensuring that packaging serves its purpose without compromising the health of our planet. The synergy between automotive manufacturers and packaging designers in Toledo, Ohio, is a testament to the potential for impactful change when industries unite under a common goal of sustainability. This convergence of expertise not only promotes innovation but also ensures that the packaging solutions developed are scalable and replicable across the industry, leading to a greener future for automotive manufacturing worldwide.

The Future of Automotive Packaging Design: Predictions and Emerging Trends in Toledo, Ohio and Beyond

In Toledo, Ohio, the automotive packaging design sector is poised to undergo significant transformations that will ripple through its broader applications beyond. As sustainability becomes a cornerstone in product development, local designers and manufacturers are increasingly focusing on eco-friendly materials and innovative packaging solutions that align with the automotive industry’s evolving needs. The future of automotive packaging design in Toledo is likely to be characterized by a shift towards biodegradable and recyclable packaging options, reducing the environmental impact associated with traditional packaging materials. This trend is driven by both regulatory pressures and consumer demand for more sustainable practices. Moreover, the integration of smart technology into packaging design is an emerging trend that promises to enhance functionality while providing valuable data on logistics and supply chain efficiency. These advancements in Toledo are indicative of a broader movement towards sustainability within the automotive packaging domain, a movement that is gaining momentum across the nation and globally.

Beyond Toledo, the predictions for the future of automotive packaging design are equally dynamic and forward-thinking. The industry is anticipated to embrace digitalization and circular economy principles, where packaging solutions are designed with end-of-life in mind. This approach not only minimizes waste but also creates opportunities for material recovery and reuse. Additionally, advancements in materials science are leading to the development of new, lightweight, and high-strength packaging materials that offer better protection for automotive components while reducing carbon footprints. As stakeholders continue to prioritize sustainability and innovation, the landscape of automotive packaging design is set to become increasingly sophisticated, with Toledo’s contributions playing a pivotal role in shaping the future of this industry.