Steel packaging solutions have become a cornerstone of sustainability within the material containment industry, offering a closed-loop recycling system that minimizes environmental impact. These solutions are characterized by their high recycling rates and durability, allowing for repeated use without compromising quality or performance. Sustainable steel packaging is tailored to various sectors, including food and beverage, chemicals, pharmaceuticals, and automotive, providing robust protection while being environmentally friendly. The energy-efficient recycling process of steel significantly reduces carbon emissions compared to producing new materials, reinforcing its sustainability credentials. Custom steel packaging options are designed for long-term use, reducing waste and promoting a circular economy by enabling the material to be recycled repeatedly without loss of quality. Companies adopting these sustainable practices not only protect their products but also demonstrate a commitment to environmental stewardship, making steel packaging solutions an ideal choice for businesses focused on safety and sustainability. Leading brands like EcoSteelPack and GreenCan exemplify this transformation with innovative packaging that supports global sustainability goals.

Steel packaging solutions stand at the forefront of eco-conscious material innovations. This article delves into the sustainability and versatility of recyclable steel packaging, highlighting its role as a responsible choice for environmentally aware industries. We explore the lifecycle of these containers, from their production to the reclamation process, emphasizing the significance of sustainable steel packaging design. Custom solutions tailored to eco-conscious brand needs are also examined, revealing how steel’s durability and resilience make it a long-term investment in packaging sustainability. Through case studies showcasing brands leading the charge, we illustrate the tangible impact of innovative steel packaging on reducing waste and promoting circular economy principles.

- Unveiling the Eco-Friendly Side of Steel Packaging Solutions: A Sustainable Choice

- The Lifecycle of Recyclable Steel Packaging: From Production to Reclamation

- Custom Steel Packaging: Tailored Solutions for Eco-Conscious Industries

- Innovations in Sustainable Steel Packaging Design

- The Durability and Resilience of Steel: A Long-Term Packaging Investment

- Case Studies: Brands Leading the Charge with Custom Sustainable Steel Packaging

Unveiling the Eco-Friendly Side of Steel Packaging Solutions: A Sustainable Choice

Steel packaging solutions have emerged as a beacon of sustainability in the realm of material containment, offering significant environmental advantages over alternative options. The lifecycle of steel packaging is notable for its high recycling rates; it can be reused time and again without loss of quality or integrity. This closed-loop system ensures that steel containers remain in circulation, minimizing the need for new materials and reducing waste accumulation. Custom steel packaging solutions are particularly adept at meeting the unique needs of various industries, from food and beverage to chemicals and pharmaceuticals, with a level of customization that maximizes product protection while remaining environmentally sound. The durability and strength of steel make it an ideal material for containers that can endure harsh handling conditions, which in turn extends the life of the packaging and further minimizes environmental impact. Moreover, the energy required to recycle steel is significantly less than that needed to produce virgin materials, making steel a sustainable choice that aligns with modern environmental standards and consumer expectations for responsible product stewardship.

The Lifecycle of Recyclable Steel Packaging: From Production to Reclamation

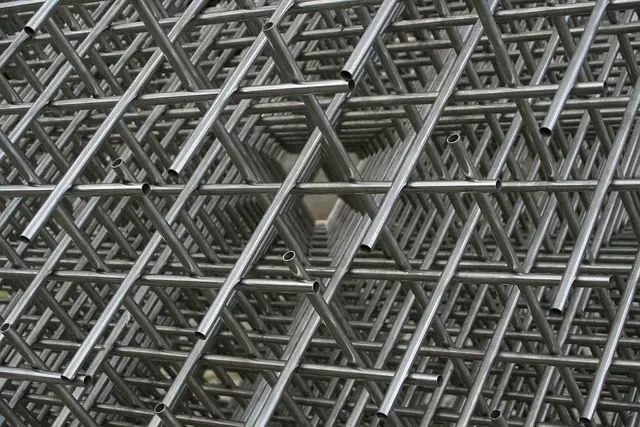

Steel packaging solutions play a pivotal role in the sustainability narrative, offering a closed-loop system that emphasizes the use of materials multiple times to minimize environmental impact. The lifecycle of recyclable steel packaging begins at the production stage where raw materials are processed into high-quality, sustainable steel packaging options. These custom steel packaging solutions are engineered not only for functionality and durability but also for ease of recycling, ensuring they serve their purpose without compromising future recycling efficiency.

Once the steel packaging has served its initial use, it enters the reclamation process. This phase is critical in maintaining the sustainability of steel as a packaging material. The collected steel packaging is sorted and cleaned to remove any contaminants. It is then sent back to manufacturing facilities where it is melted down and transformed into new steel packaging products. This process can be repeated numerous times without degrading the material’s quality, a testament to the robust nature of steel. The closed-loop system ensures minimal waste and exemplifies the circular economy model, where the end of one product’s life marks the beginning of another. The entire process showcases the resilience and adaptability of sustainable steel packaging solutions as they continue to serve society while remaining a key player in environmental conservation efforts.

Custom Steel Packaging: Tailored Solutions for Eco-Conscious Industries

In the realm of eco-conscious industrial practices, custom steel packaging solutions stand out as a beacon of sustainability and innovation. These tailored packaging options are meticulously designed to meet the specific needs of industries committed to reducing their environmental footprint. Sustainable steel packaging, with its robust durability and recyclability, offers an alternative to less eco-friendly materials, providing a reliable container for products that can be repurposed or fully recycled at the end of its lifecycle. The flexibility of custom steel packaging allows businesses to integrate design elements that optimize material usage without compromising on protection or functionality. This not only reduces waste but also aligns with the growing demand for responsible consumption and production patterns, as outlined by the United Nations’ Sustainable Development Goals. By choosing steel over other materials, companies can significantly lower their carbon footprint, as steel packaging is endlessly recyclable without loss of quality, making it a sustainable choice that supports the circular economy. The adoption of such packaging solutions underscores a commitment to environmental stewardship and a forward-thinking approach in the industry.

Innovations in Sustainable Steel Packaging Design

Innovations in sustainable steel packaging design are at the forefront of addressing environmental concerns associated with packaging materials. The shift towards eco-friendly alternatives has led to a surge in the development of steel packaging solutions that prioritize resource efficiency and reduced ecological impact. Sustainable steel packaging, characterized by its high recyclability and low energy requirements during production, is emerging as a preferred choice for industries looking to minimize their carbon footprint. Custom steel packaging options are being engineered to meet diverse needs across various sectors, including food and beverage, automotive, and pharmaceuticals. These bespoke solutions not only enhance product protection but also align with global sustainability goals by optimizing material usage and promoting the closed-loop recycling of steel containers. The durability and reusability of steel packaging make it a resilient choice that can withstand multiple life cycles without compromising integrity, ensuring that each steel package can be recycled repeatedly, thus contributing to a more sustainable future.

The Durability and Resilience of Steel: A Long-Term Packaging Investment

Steel packaging solutions have long been recognized for their exceptional durability and resilience, making them a reliable choice for safeguarding goods across various industries. The robust nature of steel means that it offers unparalleled protection against environmental factors, impact damage, and tampering, ensuring the longevity of the products contained within. This resilience is not just a short-term asset but a long-term investment; steel containers maintain their integrity over time, reducing the need for frequent replacements compared to other packaging materials. Moreover, the sustainability of steel packaging is another compelling advantage. Sustainable steel packaging solutions are designed with an emphasis on minimizing waste and energy consumption throughout the lifecycle of the product. Custom steel packaging, tailored to meet specific needs, can be recycled repeatedly without loss of quality, significantly reducing the environmental footprint associated with traditional packaging options. The recycling process for steel is highly efficient, with the material being transformed into new products again and again, thus saving natural resources and energy. Investing in steel packaging solutions not only ensures product safety but also aligns with global sustainability goals, making it a prudent choice for businesses looking to adopt eco-friendly practices without compromising on protection or performance.

Case Studies: Brands Leading the Charge with Custom Sustainable Steel Packaging

Innovative brands are setting a precedent by adopting sustainable steel packaging solutions, demonstrating a commitment to environmental stewardship and circular economy principles. Companies like EcoSteelPack have emerged as leaders in this domain, offering custom sustainable steel packaging that not only preserves the integrity of the product within but also reduces the carbon footprint associated with packaging production and disposal. Their approach involves designing packaging that can be infinitely recycled without loss of material properties, ensuring a closed-loop system that minimizes waste. Another trailblazer in this space is GreenCan, which has successfully implemented custom steel packaging solutions for a variety of industries, including food and beverage, pharmaceuticals, and personal care products. Their focus on sustainable practices has led to significant reductions in the environmental impact of their clients’ supply chains, highlighting the potential of steel as a versatile and eco-friendly packaging material. These brands are not only transforming the industry with their innovative solutions but also setting a new standard for what it means to package responsibly. Their initiatives underscore the importance of considering sustainable steel packaging as a viable option for businesses looking to make a positive environmental impact.

In conclusion, the shift towards sustainable steel packaging solutions represents a pivotal stride in the right direction for environmental stewardship. The lifecycle of recyclable steel packaging, detailed from production to reclamation, underscores its role as an enduring and eco-friendly option within the packaging industry. Custom steel packaging offers tailored solutions that cater to the needs of environmentally conscious industries, while advancements in design innovation continue to enhance the material’s sustainability profile. Notably, case studies highlighting brands that have embraced this green approach demonstrate the tangible impact and long-term investment value of sustainable steel packaging. As these initiatives gain momentum, it is clear that steel remains a resilient and viable choice for a greener future in packaging solutions.