The micro etching process in Oak Harbor, Ohio, is a cutting-edge manufacturing technique renowned for its precision and versatility. It involves applying photoresist masks followed by etched solutions or plasma to remove material with nanometer-level accuracy. This capability enables the creation of minuscule components crucial for modern electronics, medical devices, and diverse industrial applications. Micro etching enhances product performance, aesthetics, durability, and sustainability, making it a game-changer in manufacturing sectors demanding intricate, microscopic designs. By offering unparalleled precision, cost-effectiveness, and ecological benefits, micro etching is an indispensable tool shaping today's technological landscape.

“Unleashing precision and innovation, micro etching in Oak Harbor, Ohio, offers a multitude of benefits that revolutionize various industries. This intricate process, with its meticulous attention to detail, enhances materials at a microscopic level, resulting in superior aesthetics and performance. From improving surface finish to enabling miniaturization without sacrificing quality, micro etching ensures corrosion resistance and versatility in material applications. Moreover, it contributes to environmental sustainability, making it a game-changer for modern manufacturing.”

- Understanding Micro Etching: A Brief Overview

- Precision and Accuracy: The Key Advantages

- Enhancing Surface Finish for Improved Aesthetics

- Miniaturization of Components: Shrinking Without Compromising Quality

- Corrosion Resistance: Protecting Materials Over Time

- Versatility in Material Applications

- Environmental Benefits: Sustainability Through Micro Etching

Understanding Micro Etching: A Brief Overview

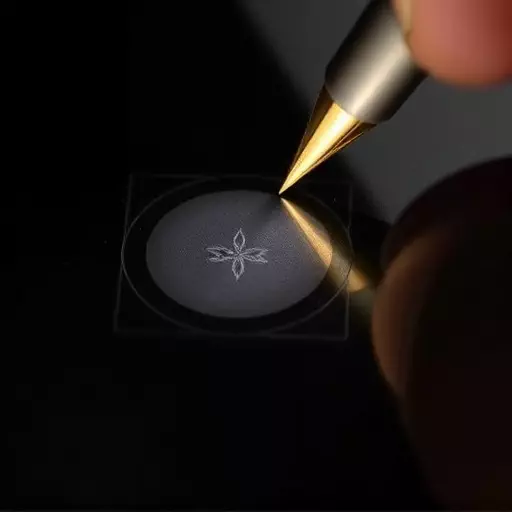

Micro etching is a highly precise manufacturing process that involves the controlled removal of material from a surface using an etched solution or plasma. This method is employed across various industries to create intricate patterns and structures on materials like silicon, glass, and metal. In Oak Harbor, Ohio, for instance, micro etching has become a cornerstone of several advanced technologies, offering numerous benefits that drive innovation.

The process begins with the application of a photoresist mask, which protects specific areas of the substrate while exposing others. This mask is then treated with an etched solution or plasma, precisely removing the unprotected material. The result is a highly detailed pattern achieved at microscopic levels—a feat unattainable through conventional machining methods. Benefits of micro etching include enhanced precision, enabling the creation of minuscule features crucial for modern electronics and medical devices. It also allows for customization on a small scale, catering to diverse applications across industries.

Precision and Accuracy: The Key Advantages

The micro etching process in Oak Harbor, Ohio, is renowned for its precision and accuracy, setting it apart from other manufacturing techniques. This advanced method involves the controlled removal of material on a microscopic scale, allowing for the creation of intricate and detailed patterns. The key advantage lies in its ability to achieve unprecedented levels of precision, often down to the nanometer range. This level of accuracy is vital for industries requiring minuscule features, such as semiconductor manufacturing, medical device production, and advanced electronic components.

By employing micro etching, manufacturers can produce components with enhanced performance and reliability. The meticulousness of the process ensures that every detail is executed precisely, leading to improved functionality and longer-lasting products. Moreover, this technique offers cost-effectiveness for custom projects, as it facilitates the creation of unique designs without significant additional costs. The benefits of micro etching are thus far-reaching, making it an indispensable tool in modern manufacturing.

Enhancing Surface Finish for Improved Aesthetics

The micro etching process offers a multitude of advantages for enhancing surface finishes, particularly in the realm of aesthetics. By employing Oak Harbor Ohio’s advanced micro etching techniques, manufacturers can achieve unparalleled levels of precision and detail on various materials. This meticulous process allows for the creation of intricate patterns, textures, and designs that elevate the visual appeal of products.

One of the key benefits is the ability to create smooth, polished surfaces with minimal imperfections. Micro etching enhances the overall aesthetics by reducing surface roughness, resulting in a more refined and visually pleasing finish. This is especially valuable for industries where appearance matters, such as electronics, automotive components, and decorative accessories. The meticulous nature of micro etching ensures that products not only look better but also feel luxurious and high-quality to the touch.

Miniaturization of Components: Shrinking Without Compromising Quality

The micro etching process in Oak Harbor, Ohio, has revolutionized the miniaturization of components, allowing for significant size reduction without sacrificing quality. This advanced technique enables manufacturers to create intricate patterns and structures on various materials, opening up a world of possibilities in diverse industries. By utilizing specialized equipment and precise control, micro etching ensures that even the tiniest details are accurately replicated, making it ideal for producing high-performance components with exceptional precision.

This technology is particularly beneficial for electronics manufacturing, where smaller dimensions lead to more compact and efficient devices. Micro etched components can enhance product aesthetics and functionality, catering to the growing demand for sleek, lightweight, and powerful gadgets. With its ability to shrink sizes while maintaining quality, micro etching plays a pivotal role in keeping up with the rapid advancements in technology, making it a key process in the modern manufacturing landscape.

Corrosion Resistance: Protecting Materials Over Time

Micro etching, a meticulous process based in Oak Harbor, Ohio, offers an array of benefits, one of which is enhanced corrosion resistance. By meticulously carving or engraving materials at a microscopic level, this technique creates a protective barrier that prevents environmental elements from compromising the integrity of the substrate. Over time, as corrosive substances come into contact with the etched surface, they are unable to penetrate the intricate patterns, thus preserving the material’s original properties and extending its lifespan.

This advantage is particularly valuable in industries where materials are exposed to harsh conditions or corrosive substances. Whether it’s in automotive parts, electronics, or aerospace applications, micro etching ensures that components remain sturdy and reliable for extended periods, outperforming traditional manufacturing methods that may fall short in the face of corrosion.

Versatility in Material Applications

The versatility of micro etching is a significant advantage that makes it an attractive option for diverse material applications. This precise process can be applied to various materials, including metals, plastics, and even certain types of glass, allowing for endless possibilities in design and functionality. In Oak Harbor, Ohio, where specialized micro etching services are available, manufacturers and artisans alike take advantage of this technology to create intricate patterns, textures, and structures that would be challenging or impossible to achieve with traditional methods.

One of the key benefits of micro etching is its ability to enhance the performance and aesthetic appeal of materials. For instance, in the medical device industry, micro etching can create delicate channels and patterns on surgical instruments, improving their functionality and sterility. Similarly, in consumer electronics, it enables the production of smaller, more efficient components. Beyond functional enhancements, micro etching adds a layer of visual sophistication, making products more aesthetically pleasing with intricate designs that captivate users.

Environmental Benefits: Sustainability Through Micro Etching

The micro etching process in Oak Harbor, Ohio, is more than just a precision technique; it’s an environmental game-changer. This advanced manufacturing method offers significant sustainability advantages by reducing material waste and minimizing the need for harsh chemicals often associated with traditional fabrication processes. Here, the focus on micro-scale detail results in cleaner, more efficient production, ensuring that every aspect of the process is designed to minimize ecological impact.

Through micro etching, manufacturers can create intricate designs and components while using fewer resources. This not only reduces environmental strain but also contributes to cost savings. The precision involved allows for exacting specifications, eliminating excess material and the subsequent waste disposal issues. As a result, the benefits of micro etching extend far beyond the product itself, making it an eco-friendly choice in the manufacturing landscape.